Rabdosia serra (Maxim.) hara extract, preparing process and application thereof

A technology of Xihuangcao and extract, which is applied in the field of traditional Chinese medicine, can solve problems such as difficult retention, backward preparation technology, and inconvenient administration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

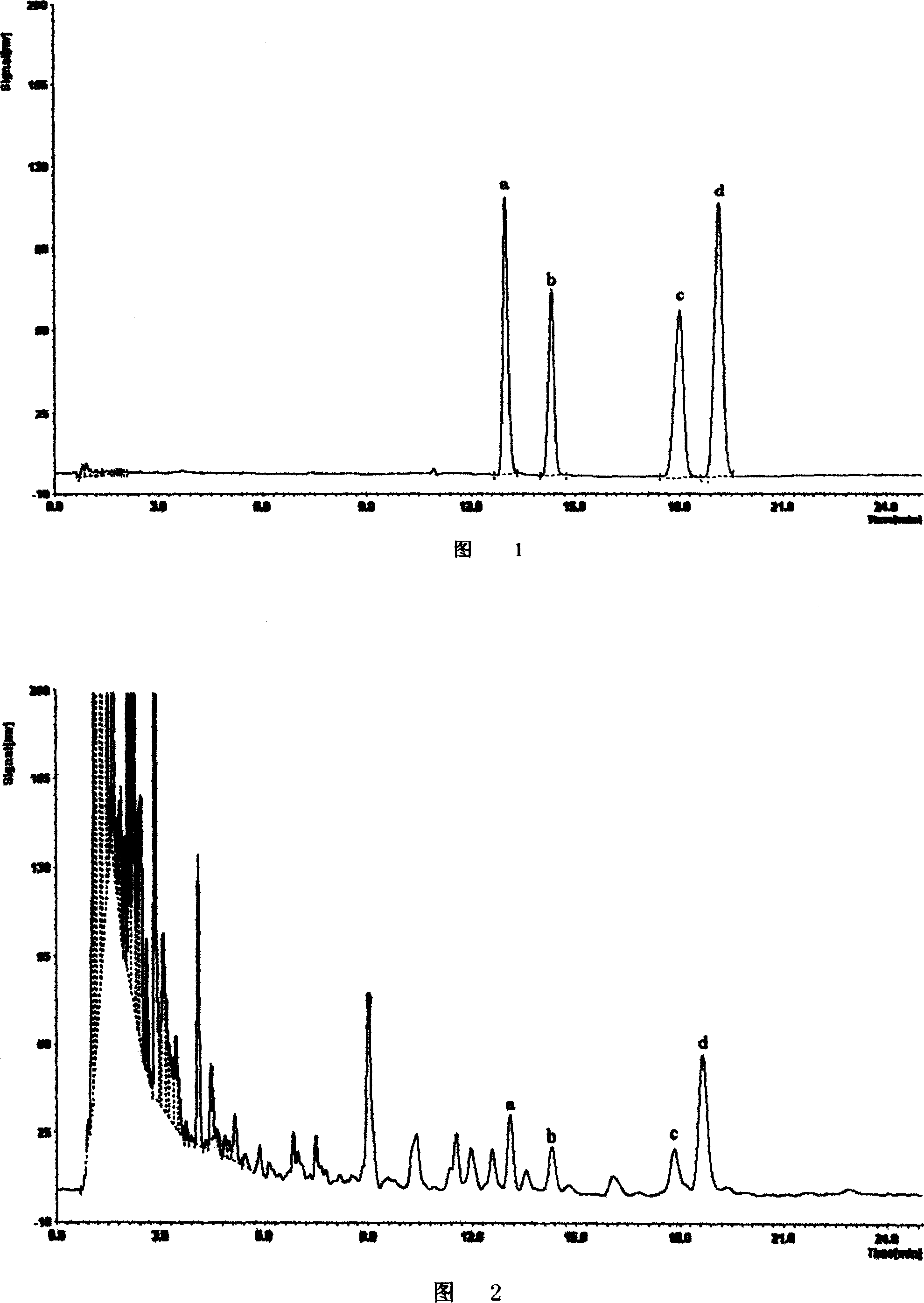

Image

Examples

example 1

[0060] Take 2000g of fresh and dried Xihuangcao, cut into 1-2cm pieces.

[0061] Take a small section of Xihuangcao, add 12 times of water, soak for 12 hours, heat and extract at 100°C for 1.5 hours, filter while hot, add 10 times of water to the dregs, heat and extract for 1 hour, and filter while hot. Combine the two ethanol extracts; concentrate the water extract to contain 0.90g of the original medicinal material per milliliter, ultracentrifuge at 5000rpm at 5-20°C, take the supernatant and add it to the treated AB-8 macroporous adsorption resin (produced by Tianjin Nankai University Chemical Factory), with a flow rate of 2BV / h (column volume per hour) on the macroporous adsorption resin column, after the adsorption is saturated, first use 6BV water to elute with a flow rate of 1.5BV / h, and then sequentially Elute with 5BV of 60% ethanol and 10BV of 80% ethanol at a flow rate of 1BV / h, collect the eluate with a concentration of 80% ethanol, concentrate, and spray dry.

[...

example 2

[0064] Take 1000g of fresh and dried Xihuangcao, cut into 1-2cm pieces.

[0065] Take a small section of Xihuangcao, add 15 times of water, soak for 12 hours, heat and extract at 100°C for 1.0 hour, filter while hot, add 10 times of water to the dregs, heat and extract for 0.5 hour, and filter while hot. Combine the two ethanol extracts; concentrate the water extract to contain 0.74g of the original medicinal material per milliliter, ultracentrifuge at 8000rpm at 5-20°C, take the supernatant and add it to the treated AB-8 macroporous adsorption resin (produced by Tianjin Nankai University Chemical Factory), with a flow rate of 3BV / h (column volume per hour) on the macroporous adsorption resin column, after the adsorption is saturated, first use 6BV water to elute with a flow rate of 0.8BV / h, and then sequentially Elute with 3BV 60% ethanol, 6BV 80% ethanol at a flow rate of 1BV / h, collect the 80% ethanol eluate, concentrate, and spray dry; the resulting extract contains 3.24% ...

example 3

[0067] Take 2000g of fresh and dried Xihuangcao, cut into 1-2cm pieces.

[0068] Take a small section of Xihuangcao, add 12 times of water, soak for 12 hours, heat and extract at 100°C for 1.5 hours, filter while hot, add 10 times of water to the dregs, heat and extract for 1 hour, and filter while hot. Combine the two ethanol extracts; concentrate the water extract to contain 0.90g of the original medicinal material per milliliter, ultracentrifuge at 500rpm at 5-20°C, take the supernatant and add it to the treated AB-8 macroporous adsorption resin (produced by Tianjin Nankai University Chemical Factory), with a flow rate of 2BV / h (column volume per hour) on the macroporous adsorption resin column, after the adsorption is saturated, first use 6BV water to elute with a flow rate of 1.5BV / h, and then sequentially Elute with 5BV 60% ethanol, 8BV 80% ethanol at a flow rate of 1BV / h, collect the 80% ethanol eluate, concentrate, and spray dry; the resulting extract contains 3.81% 2α...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com