Injection moulding heating method for diamond rope saw and apparatus

A diamond wire saw and heating device technology, applied in electric heating devices, stone processing equipment, stone processing tools, etc., can solve the problems of unstable plastic solidification molding quality, different heating times of steel wire ropes, and inability to heat metal molds, etc., to achieve convenient power supply Heating and injection molding, improving the quality of plastic curing molding, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

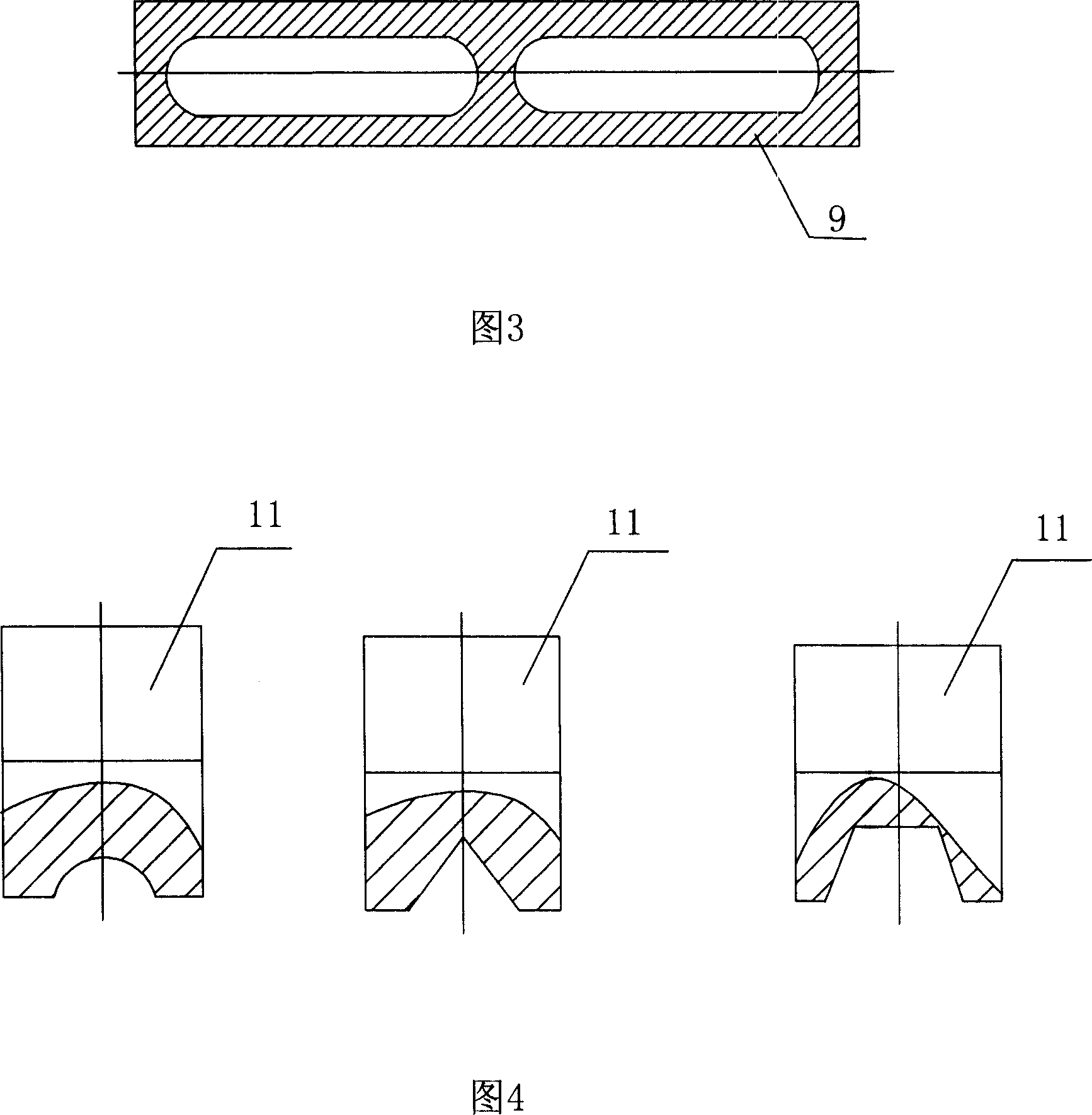

[0021] Non-limiting examples of the injection heating method of the diamond wire saw of the present invention are as follows: the two ends of the wire rope to be injected into the beaded wire rope are energized, and the resistance heat generation of the wire rope is used for self-heating, reaching 40 ° C ~ 100 ° C (according to the properties of the plastic used). ), the power is turned off, and the heated steel wire rope with beads is sent to the injection mold for injection molding. In order to reduce the cooling rate of the plastic in the injection mold, the metal mold is heated with electricity when it is working, and a certain temperature is maintained at 40°C to 70°C.

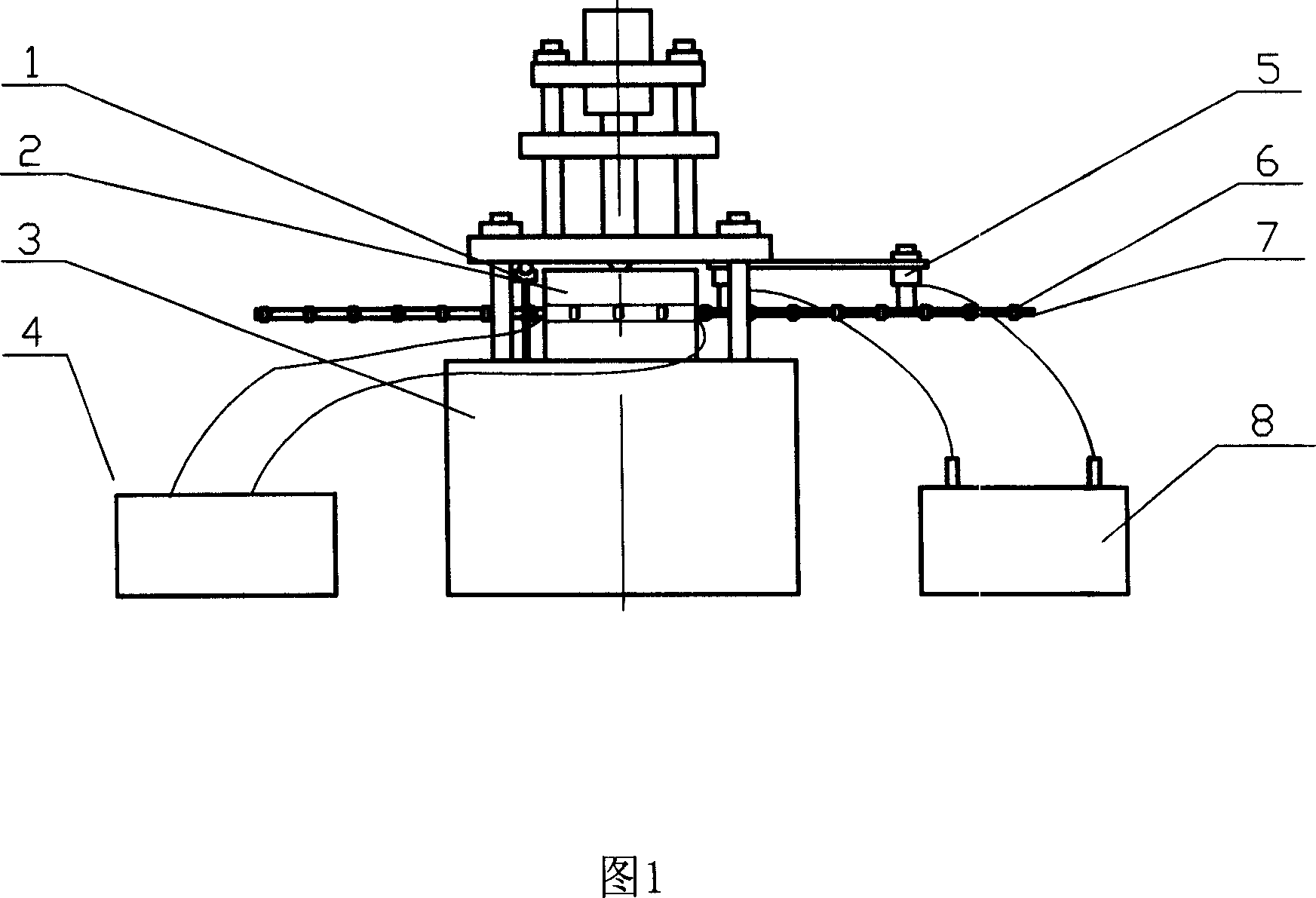

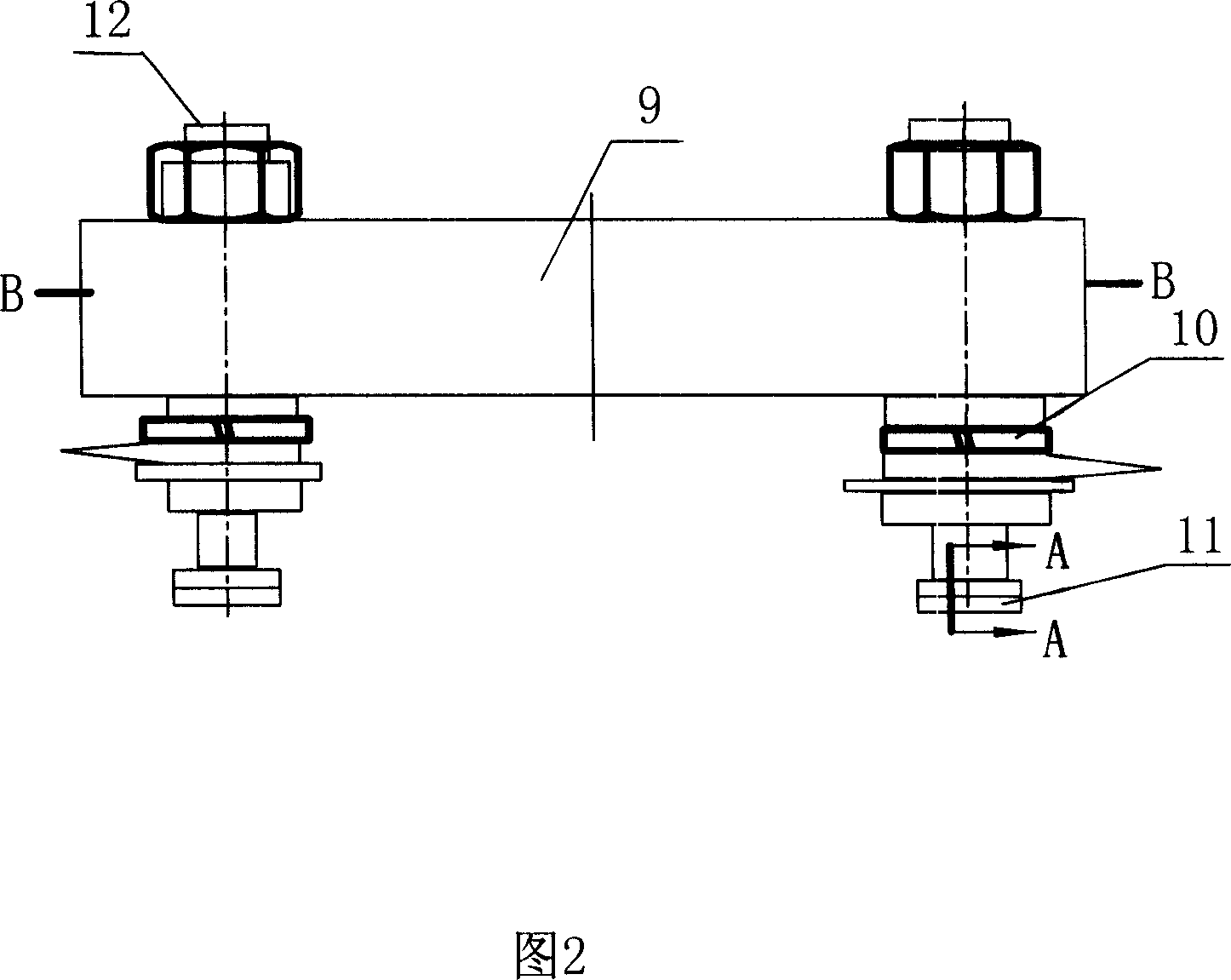

[0022] The embodiment of the wire rope saw injection heating device is shown in Figure 1. The metal injection mold 2 is installed on the operating platform of the injection molding machine 3, and the wire rope 7 with the beads 6 is fed into the mold 2 from the right side of the injection mold. This side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com