Test bench for performance of hybrid power vehicle transmission system

A hybrid electric vehicle and transmission system technology, applied in the field of hybrid electric vehicle transmission system performance test bench, can solve the problems of not being able to measure the individual torque of the engine or ISG motor, not being able to evaluate the fuel economy of the power system, and not measuring the fuel consumption of the system, etc. To achieve the effect of easy control and implementation, simple test scheme and complete functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

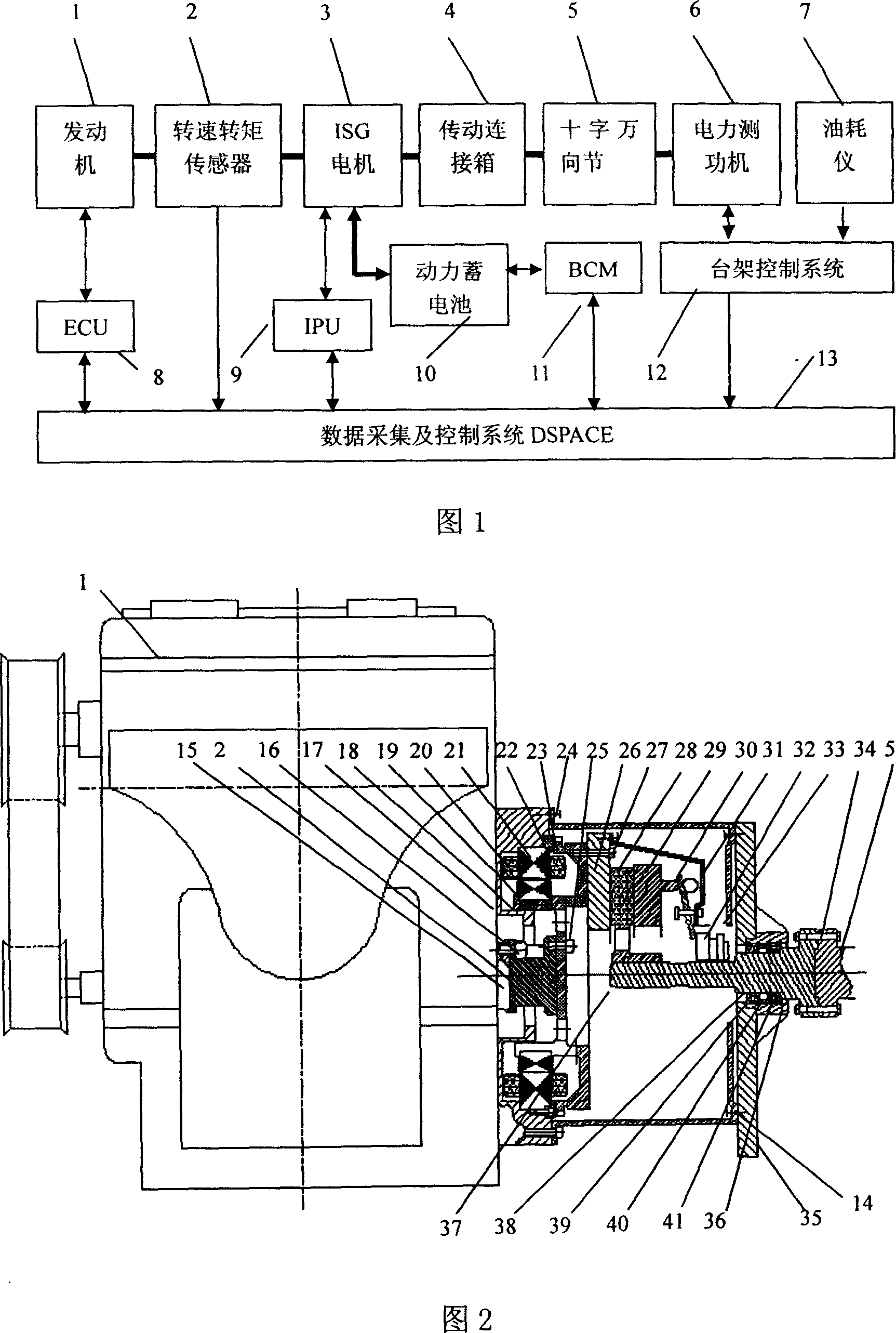

[0012] Fig. 1 has provided the schematic block diagram of structure of the present invention: engine 1 and ISG motor 3 are integrated into powertrain, and rotational speed torque sensor 2 is installed between engine 1 and ISG motor 3, can measure the rotational speed and the torque of engine 1; The powertrain is connected to the electric dynamometer 6 through the transmission connection support box 4 and the cross universal joint 5. The electric dynamometer 6 measures the speed and torque of the engine 1 / ISG motor 3 powertrain; the ISG motor 3 It is connected with the power battery 10 (Ni-MH power battery) through wires, the operation of the engine 1 is controlled by the engine controller ECU 8, the operation of the ISG motor 3 is controlled by the motor controller IPU 9, and the power battery 10 is controlled by the battery management system BCM 11 for management, the loading control of the electric dynamometer 6 and the fuel consumption meter 7 of the system are controlled an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com