A kind of preparation method of silver nanowire grid electrode

A silver nanowire, grid electrode technology, applied in nanotechnology, nanotechnology, cable/conductor manufacturing and other directions, can solve the problem of high annealing temperature, achieve the effect of simple preparation process, optimized preparation process and good support conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

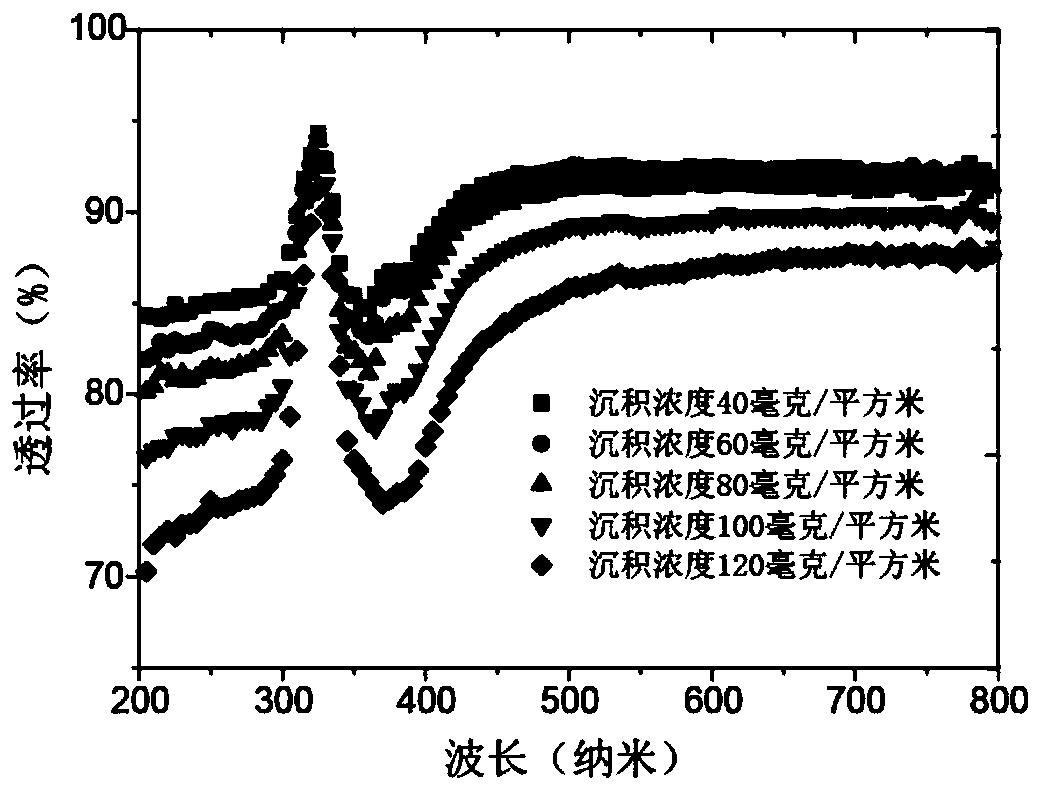

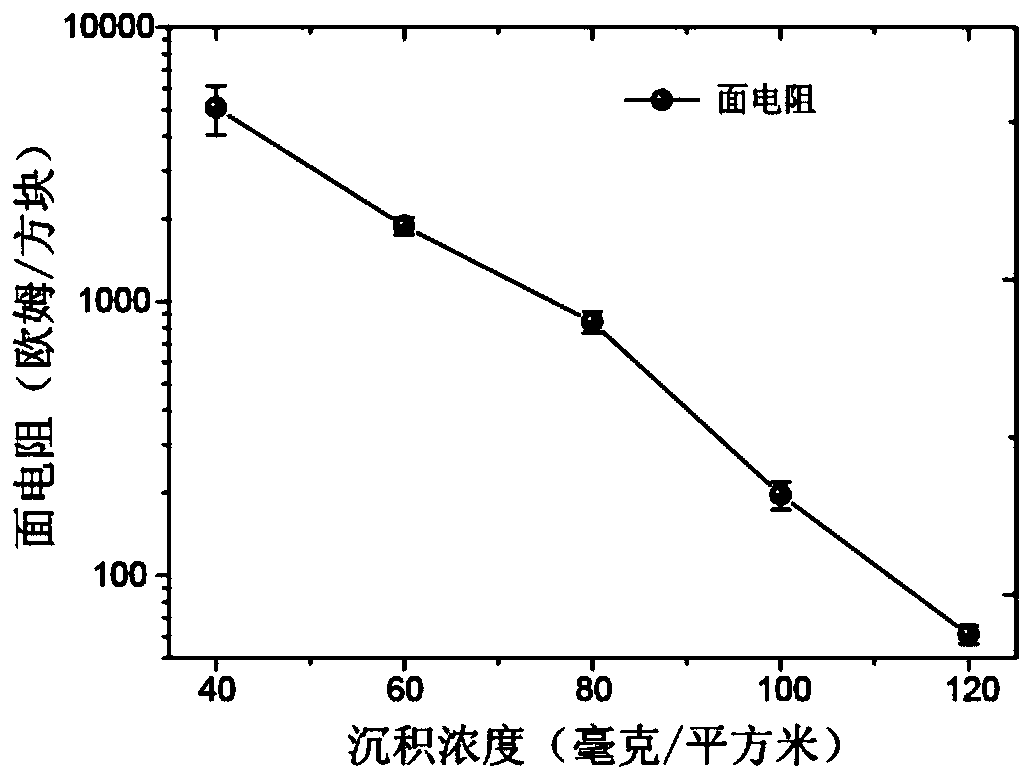

[0036] This example is used to illustrate the preparation method of the silver nanowire grid electrode disclosed in the present invention.

[0037] (1) Clean the substrate, ultrasonically clean it in trichlorethylene, acetone, absolute ethanol, and deionized water, and dry it with nitrogen.

[0038] (2) Take an appropriate amount of silver nanowire suspension in ethanol, add a certain amount of absolute ethanol solution, and dilute the silver nanowire suspension to a concentration of 0.1 mg / ml.

[0039] (3) Specific steps for preparing silver nanowire grid structure by drop coating method: ①According to the size of the substrate, use a 1 square centimeter quartz plate this time, and use a pipette gun to take the silver nanowires diluted to 0.1 mg / ml 10 microliters of the suspension was drop-coated on the substrate, and the solution spread over the entire substrate. After the solution evaporated naturally, the silver nanowires naturally settled on the substrate by their own wei...

Embodiment 2

[0042] This example is used to illustrate the preparation method of the silver nanowire grid electrode disclosed in the present invention.

[0043] (1) Clean the substrate, ultrasonically clean it in trichlorethylene, acetone, absolute ethanol, and deionized water, and dry it with nitrogen.

[0044] (2) Take an appropriate amount of silver nanowire suspension in ethanol, add a certain amount of absolute ethanol solution, and dilute the silver nanowire suspension to a concentration of 0.1 mg / ml.

[0045](3) Specific steps for preparing silver nanowire grid structure by drop coating method: ①According to the size of the substrate, use a 1 square centimeter quartz plate this time, and use a pipette gun to take the silver nanowires diluted to 0.1 mg / ml 10 microliters of the suspension was drop-coated on the substrate, and the solution spread over the entire substrate. After the solution evaporated naturally, the silver nanowires naturally settled on the substrate by their own weig...

Embodiment 3

[0048] This example is used to illustrate the preparation method of the silver nanowire grid electrode disclosed in the present invention.

[0049] (1) Clean the substrate, ultrasonically clean it in trichlorethylene, acetone, absolute ethanol, and deionized water, and dry it with nitrogen.

[0050] (2) Take an appropriate amount of silver nanowire suspension in ethanol, add a certain amount of absolute ethanol solution, and dilute the silver nanowire suspension to a concentration of 0.1 mg / ml.

[0051] (3) Specific steps for preparing silver nanowire grid structure by drop coating method: ①According to the size of the substrate, use a 1 square centimeter quartz plate this time, and use a pipette gun to take the silver nanowires diluted to 0.1 mg / ml 10 microliters of the suspension was drop-coated on the substrate, and the solution spread over the entire substrate. After the solution evaporated naturally, the silver nanowires naturally settled on the substrate by their own wei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com