Automation titrimetric analysis method and uses thereof

A titration analysis and titration technology, which is applied in the field of capacity analysis, can solve the problems that the capacity analysis is simple, fast, intelligent, automatic, large error in titration point results, and lack of operability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Titrate 25.00ml sodium hydroxide sample solution with the hydrochloric acid of 0.2593mol / L (accurate concentration sees Table 2)

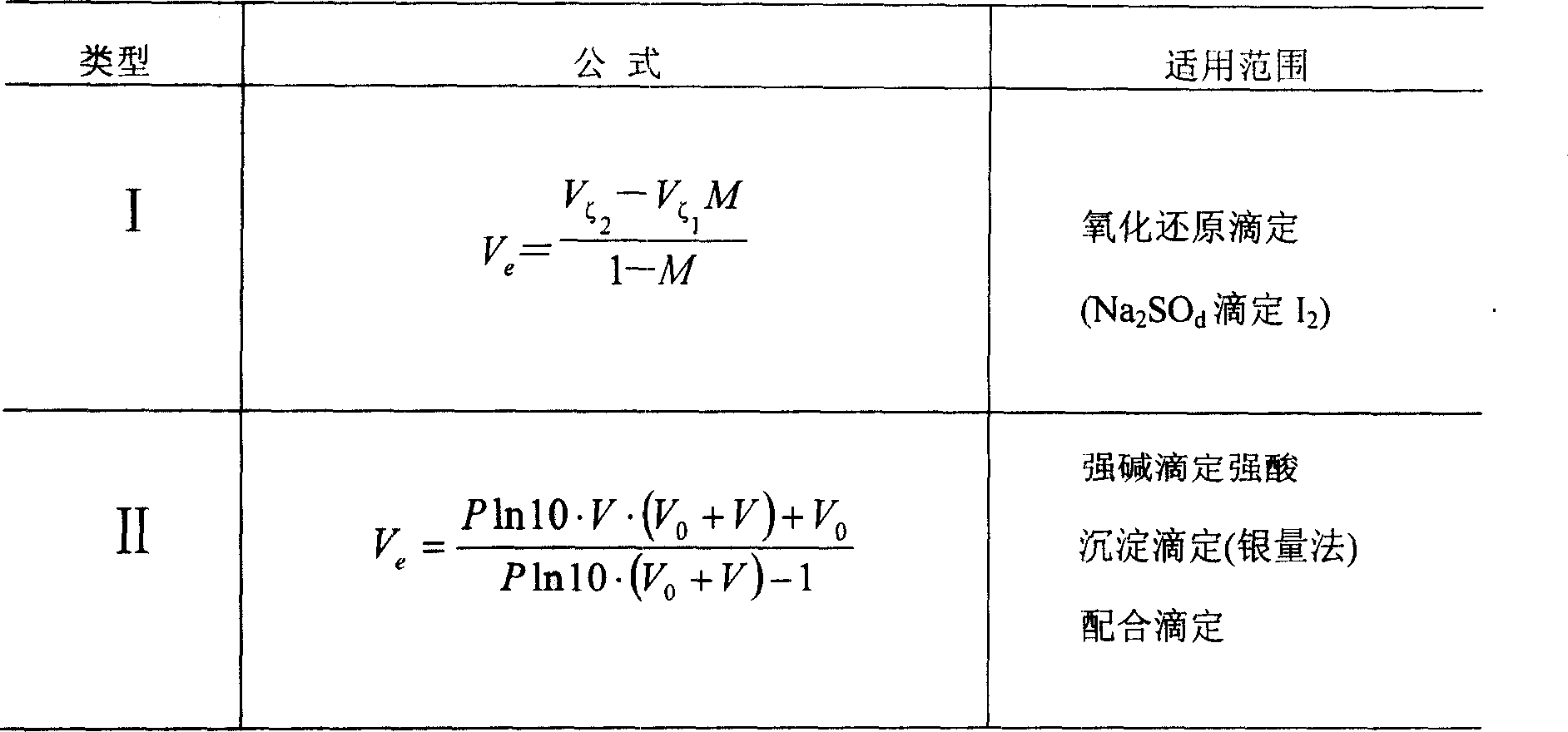

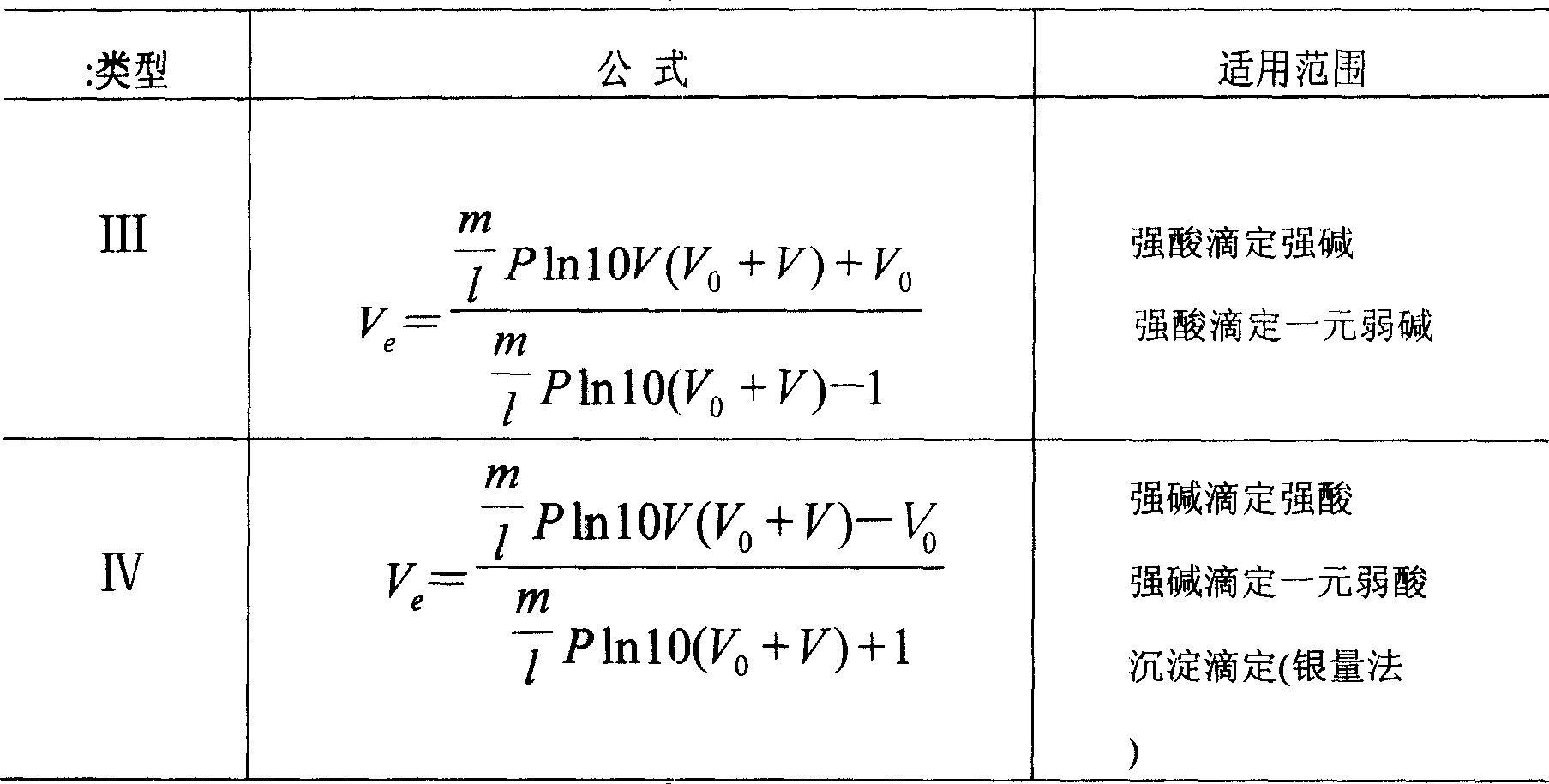

[0042] Operation process: Precisely measure 25.00ml of sodium hydroxide sample solution in a 100ml dry beaker, add a stirring bar, place it on a Metrohm776Dosimat potentiometric titrator, and connect the 827PHlabPH meter and LL Primatrode NTC glass composite electrode (both produced by Metrohm, Switzerland) Connect well, insert the electrode, start the magnetic stirrer, add 29.00ml of hydrochloric acid standard solution at a time, and read the pH after the potential is stable. 1 , then add 0.50ml standard solution, after the potential is stable, read the pH 2 , the above data V 1 、PH 1 ;V 2 、PH 2 Input computer, according to preceding table 1, select titration formula IV, calculate, repeat three titrations, its result and the comparison with existing method (Feng Junxian's two-point titration method, hereinafter referred to as " Feng met...

Embodiment 2

[0046] Titrate 25.00ml sodium chloride sample solution with the silver nitrate of 0.1006mol / L (accurate concentration sees Table 3)

[0047] Operation process: Precisely measure 25.00ml of the sodium chloride sample solution in a 100ml dry beaker, add a stirring bar, place it on the Metrohm776Dosimat potentiometric titrator, put the 827PHlabPH meter and the 6.0430.100Ag Titrode Pt composite electrode (all produced by Metrohm, Switzerland) ) is connected, insert the electrode, start the magnetic stirrer, add 26.00ml of silver nitrate standard solution at a time, and read PX after the potential is stable. 1 , then add 1.00ml standard solution, after the potential is stable, read PX 2 , the above data V 1 、PX 1 ;V 2 、PX 2 , input computer, according to preceding table 1, select titration formula IV, calculate, repeat three titrations, its result and the comparison with existing method (Feng method) are as follows:

[0048] table 3

[0049] sample

Embodiment 3

[0051] With the sodium hydroxide titration 25.00ml acetic acid sample solution of 0.1090mol / L (accurate concentration sees Table 4)

[0052] Operation process: Precisely measure 25.00ml of acetic acid sample solution in a 100ml dry beaker, add a stirring bar, place it on the Metrohm776Dosimat potentiometric titrator, connect the 827PHlabPH meter to the LL Primatrode NTC glass composite electrode (both produced by Metrohm, Switzerland) , insert the electrode, start the magnetic stirrer, add 26.00ml sodium hydroxide standard solution at a time, and read the pH after the potential is stable. 1 , then add 1.00ml standard solution, after the potential is stable, read the pH 2 , the above data V 1 、PH 1 ;V 2 、PH 2 , input computer, according to preceding table 1, select titration formula IV, calculate, repeat three titrations, its result and the comparison with existing method (Feng method) are as follows:

[0053] Table 4

[0054] Sample

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com