Preparing method of 3,4,3',4'-biphenyltetracarbosylic dianhydride

A technology of biphenyltetracarboxylic dianhydride and biphenyltetracarboxylic dianhydride, which is applied in the field of preparation of 3.4.3'.4'-biphenyltetracarboxylic dianhydride, can solve problems such as potential safety hazards and increase the cost of PBDA.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

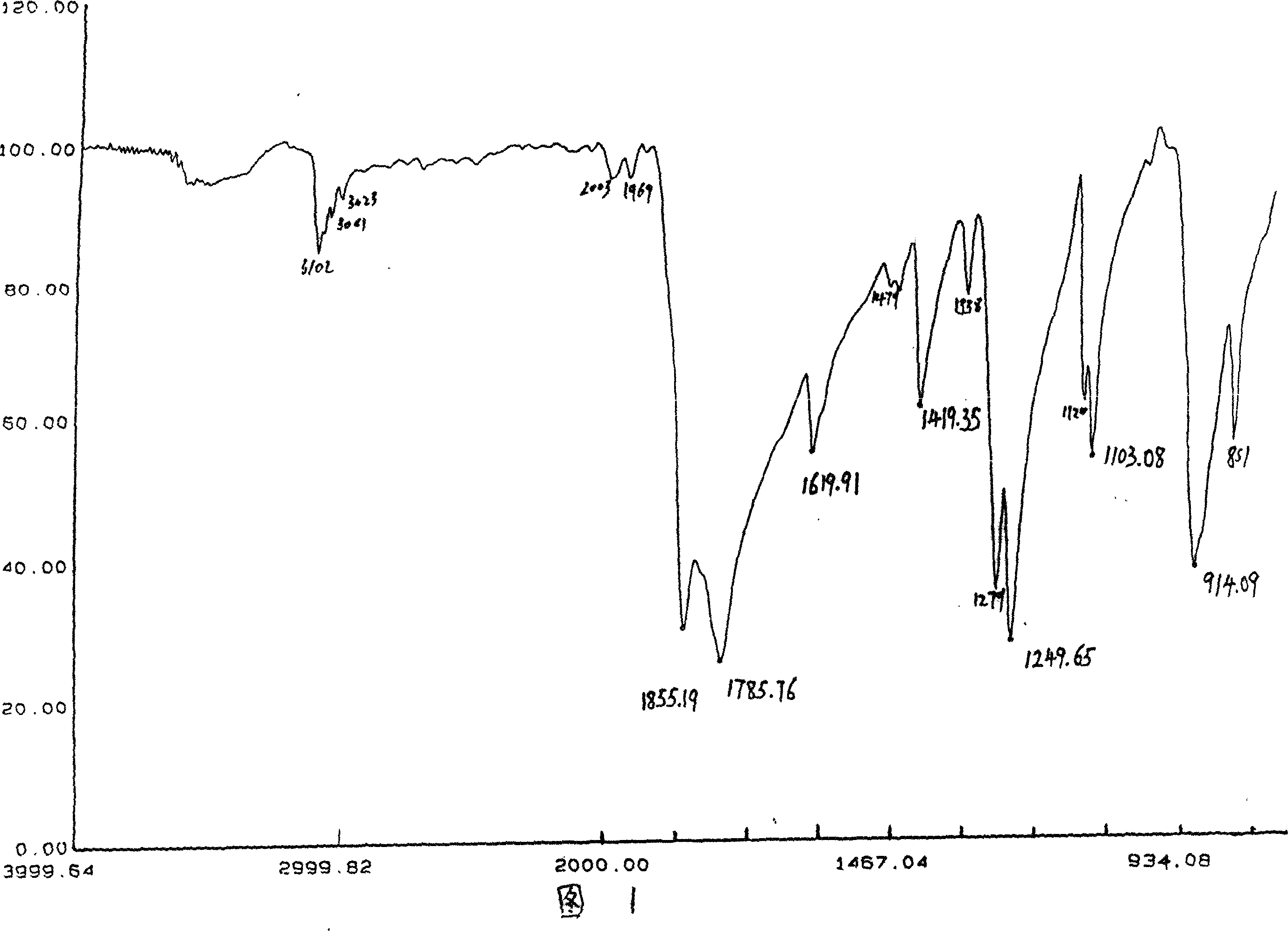

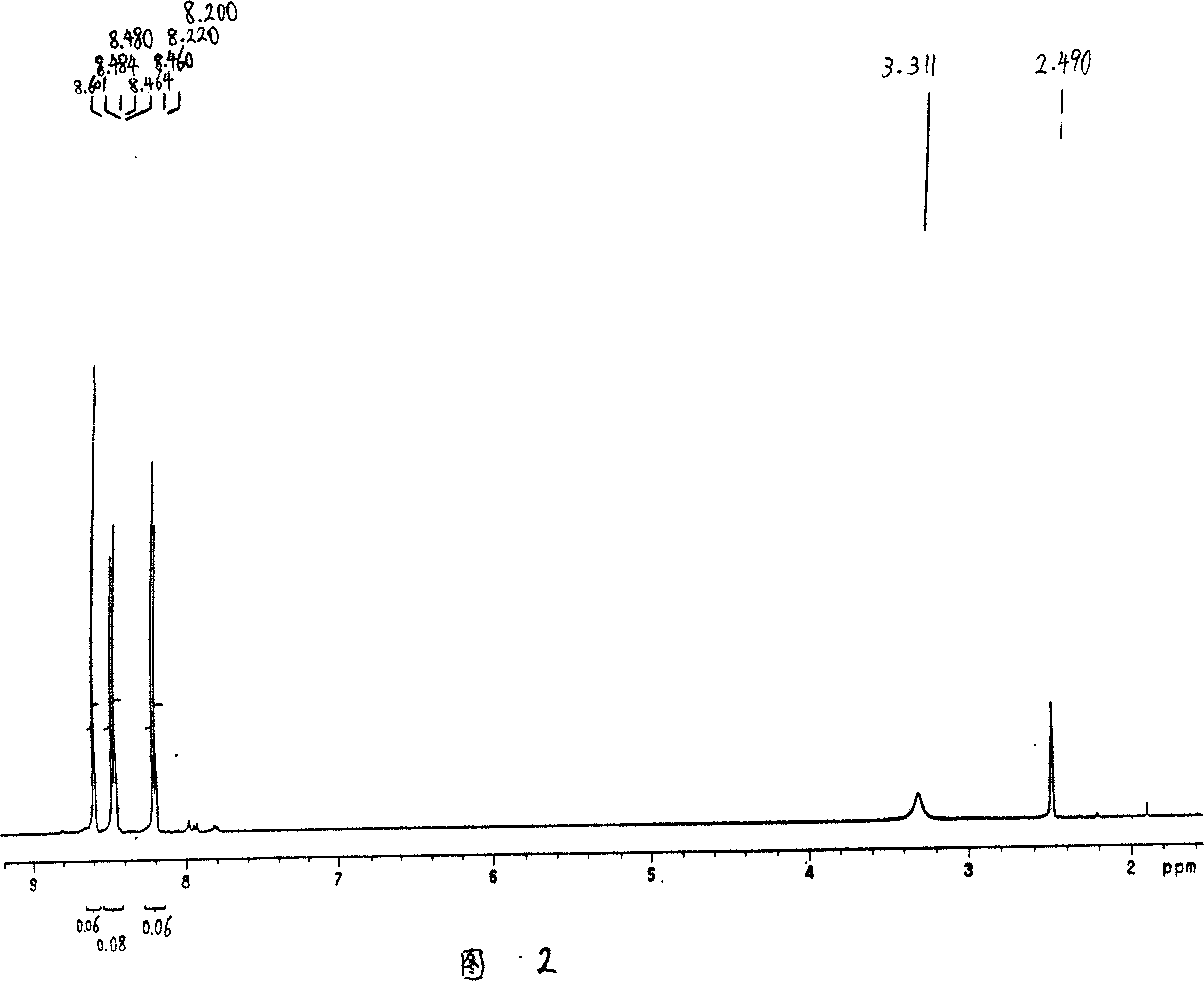

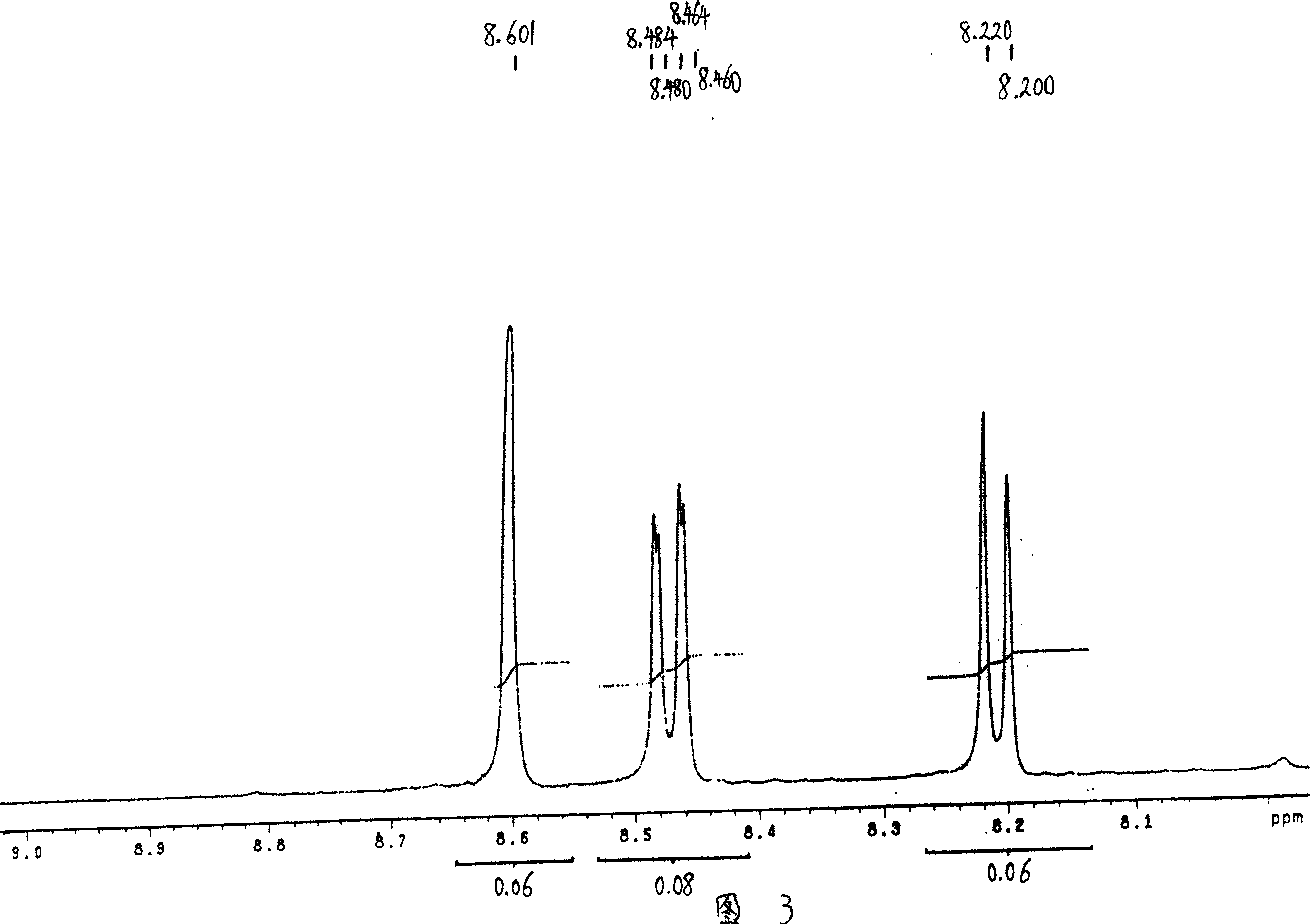

Image

Examples

Embodiment

[0040] The preparation of A, 4-chlorophthalic acid dimethyl ester:

[0041]

[0042] Add 91.2g (0.5mol) of 4-chlorophthalic anhydride, 9.1g of p-toluenesulfonic acid and 800ml of methanol into a 2000ml four-necked flask, and install a reflux condenser, a thermometer, a stirrer and a 250ml dropping funnel. Start stirring, heat the electric heating mantle to reflux, keep reflux for 4 hours, then change the reflux to distillation, every time 100ml of methanol is evaporated, add 100ml of fresh methanol from the dropping funnel, add four times like this, and finally recover all the residual methanol ( The temperature of the kettle bottle must not exceed 80°C), then turn on the water pump to pump under reduced pressure for 1 hour, vent it after cooling down, add 800ml of deionized water and stir for 5 minutes, then transfer to a 1000ml separatory funnel to stand for stratification, separate the water layer, add the oil layer After dissolving 600ml of chloroform, add 300ml of wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com