Gas-liquid polyphase flow separating rectifying device and measurement device thereof

A rectifier and multiphase flow technology, applied in the field of gas-liquid multiphase flow separation rectifier, can solve the problems of low measurement accuracy, high calibration cost, inability to realize real-time online measurement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

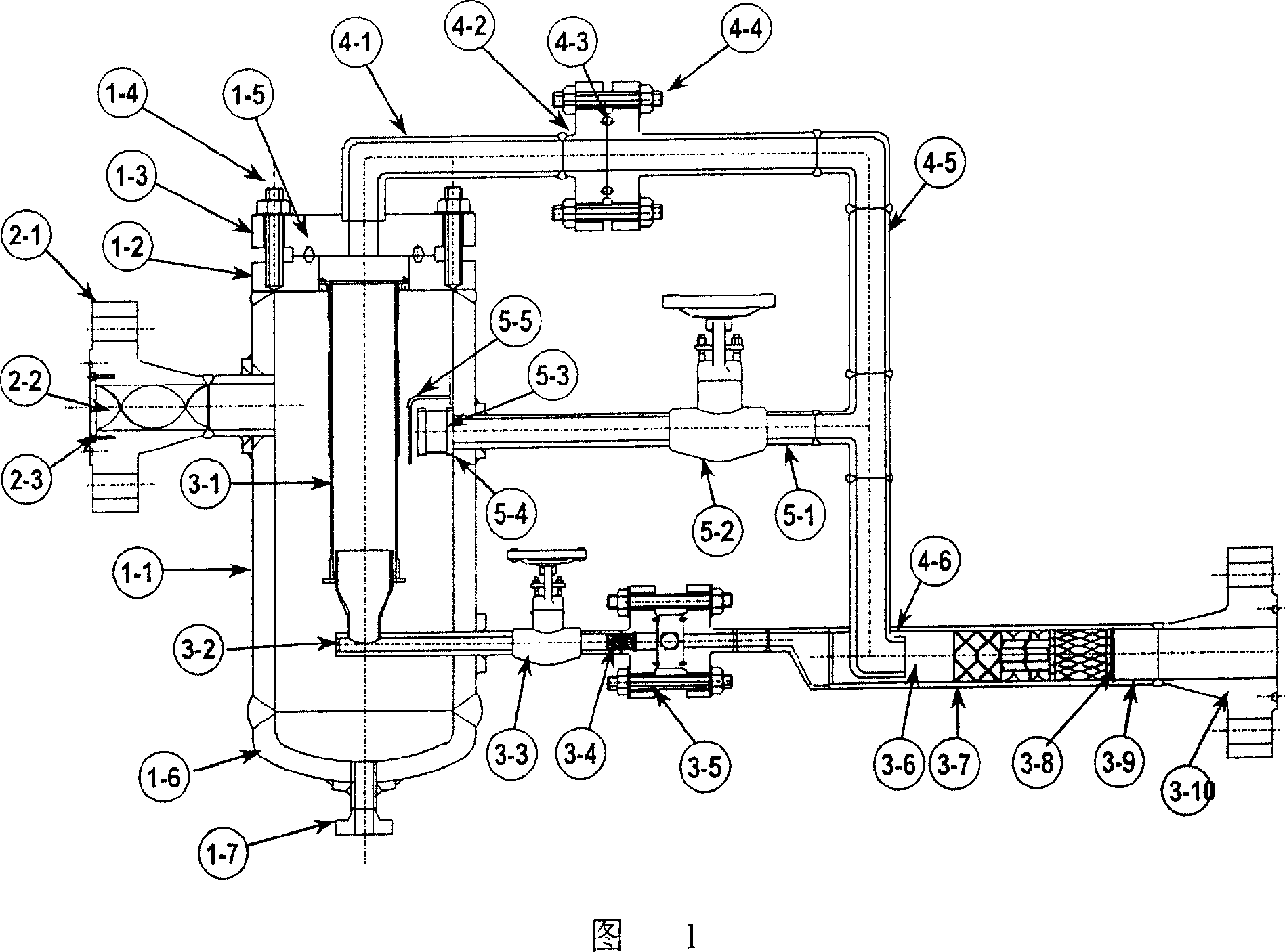

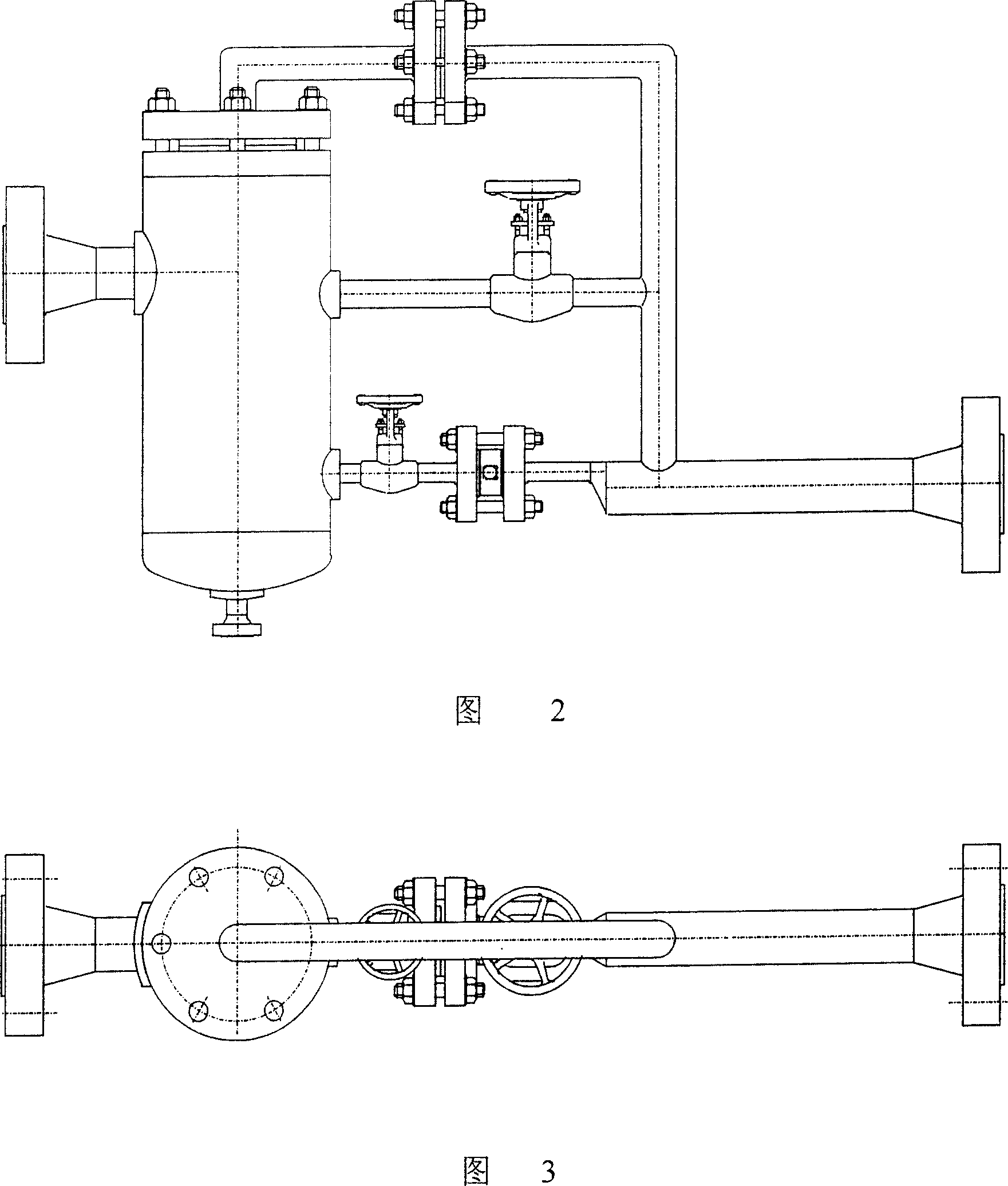

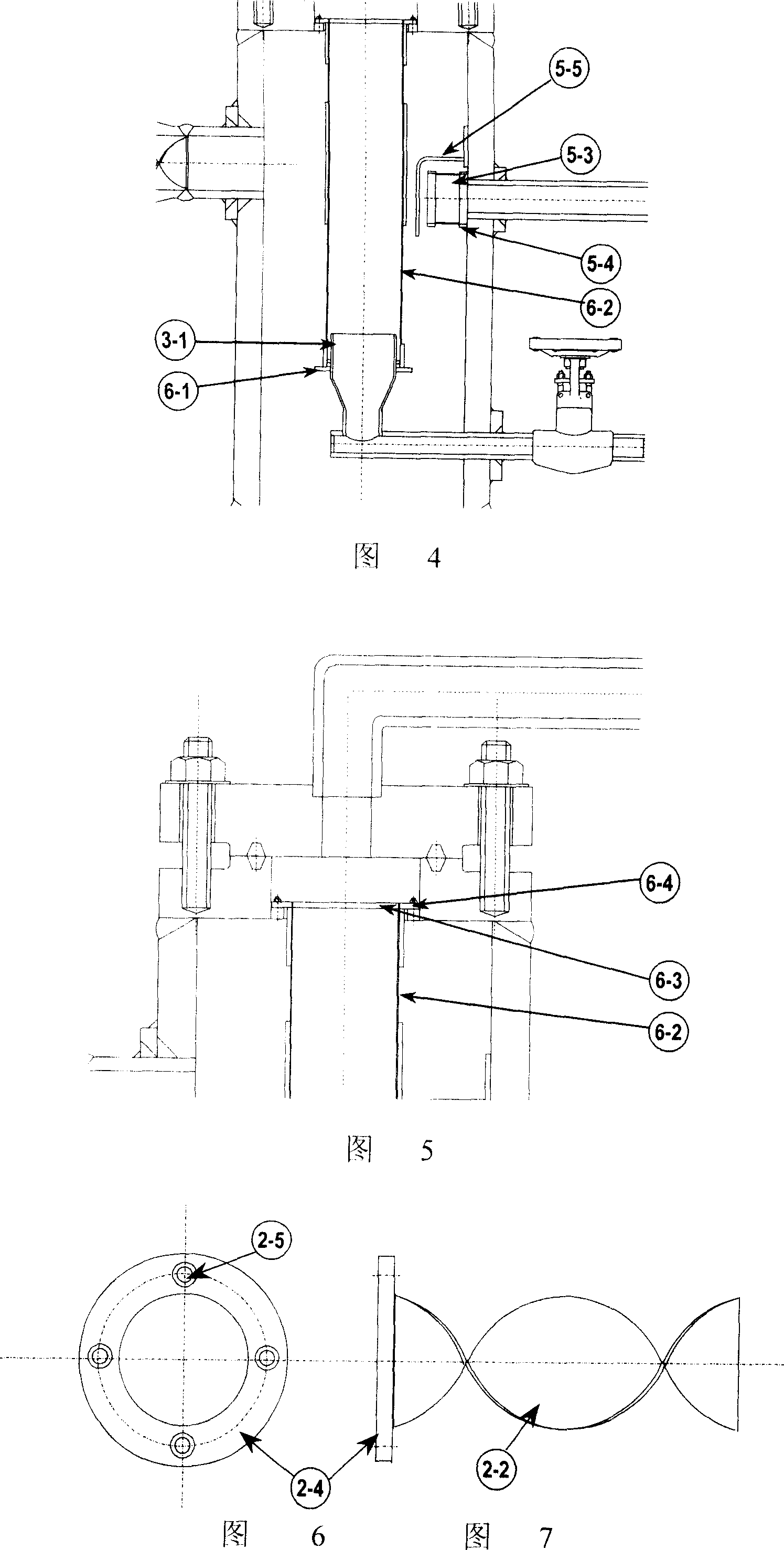

[0077]Referring to Fig. 1, Fig. 2, Fig. 3, Fig. 4, Fig. 5, a gas-liquid multiphase flow separation and rectification device includes a casing (1), and the inside of the casing (1) is a separation chamber, and the casing (1) ) is provided with an introduction tube (2) on the upper side, and the introduction tube (2) is connected with an outer tube for introducing fluid; the lower side of the shell (1) is provided with a liquid collection conduit (3), and the The liquid collection conduit (3) stretches into the bottom of the separation chamber, and the liquid collection conduit (3) includes a filter (6-2), a liquid collector (3-1), a liquid conduit (3-2), a liquid mixing part, gas-liquid mixing section (3-6), gas-liquid rectifying section (3-7), and outlet section; the bottom of the shell (1) is provided with a discharge conduit (1-7); the upper part of the shell is provided with Gas conduit (4-1), the gas conduit includes a bent pipe communicating with the upper part of the hou...

Embodiment 2

[0082] With reference to Fig. 1, Fig. 2, Fig. 3, Fig. 4, Fig. 5, Fig. 6, Fig. 7, in the present embodiment, a constant helix type vortexer is installed in the described introduction pipe, and the rotation angle of the described constant helical monomer is 180 degrees; the introduction section of the liquid conduit is provided with a first helical beam static mixer (3-4), and the helical beam static mixer includes three or more than three helical monomers, Each helical monomer has the same size; the adjacent helical monomers are tangent or approximately tangent to the pipe wall of the pipeline; the helix angle of the helical monomers is 180 Spend.

[0083] The main homogeneous rectifying mixer includes a front thin plate cross mixer and a rear helical bundle static mixer. The secondary mixer is a helical bundle static mixer. The helical bundle type static mixer includes no less than three helical units, and each helical unit is fixedly connected to each other to form a helica...

Embodiment 3

[0087] With reference to Fig. 8, a typical application example of the present invention is to utilize the oil-moisture sensor to measure the oil-moisture ratio in the liquid, utilize the speed sensor to measure the volume flow rate of the mixed fluid and utilize the Venturi principle to measure the components of liquid and gas, thereby realizing A new type of fluid instrument for multiphase fluid measurement. This embodiment has the advantages of simple and compact structure, small volume, low cost, simple explosion-proof safety and the like. And the production verification has been carried out, and the design effect has been achieved. This embodiment consists of two parts, namely a signal collection system and a signal processing system. The signal collection system consists of a special static homogeneous rectifier mixer (3-7) arranged inside the aforementioned fluid outlet pipe, a differential pressure gauge (8) for measuring the pressure difference of the static mixer, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com