A blocking technology of SF6 gas insulation power device leakage

A technology for power equipment and gas insulation, applied to electrical components, switchgear settings, switchgear, etc., can solve problems such as SF6 leakage, threats to safe operation of equipment, and poor quality and effect of plugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

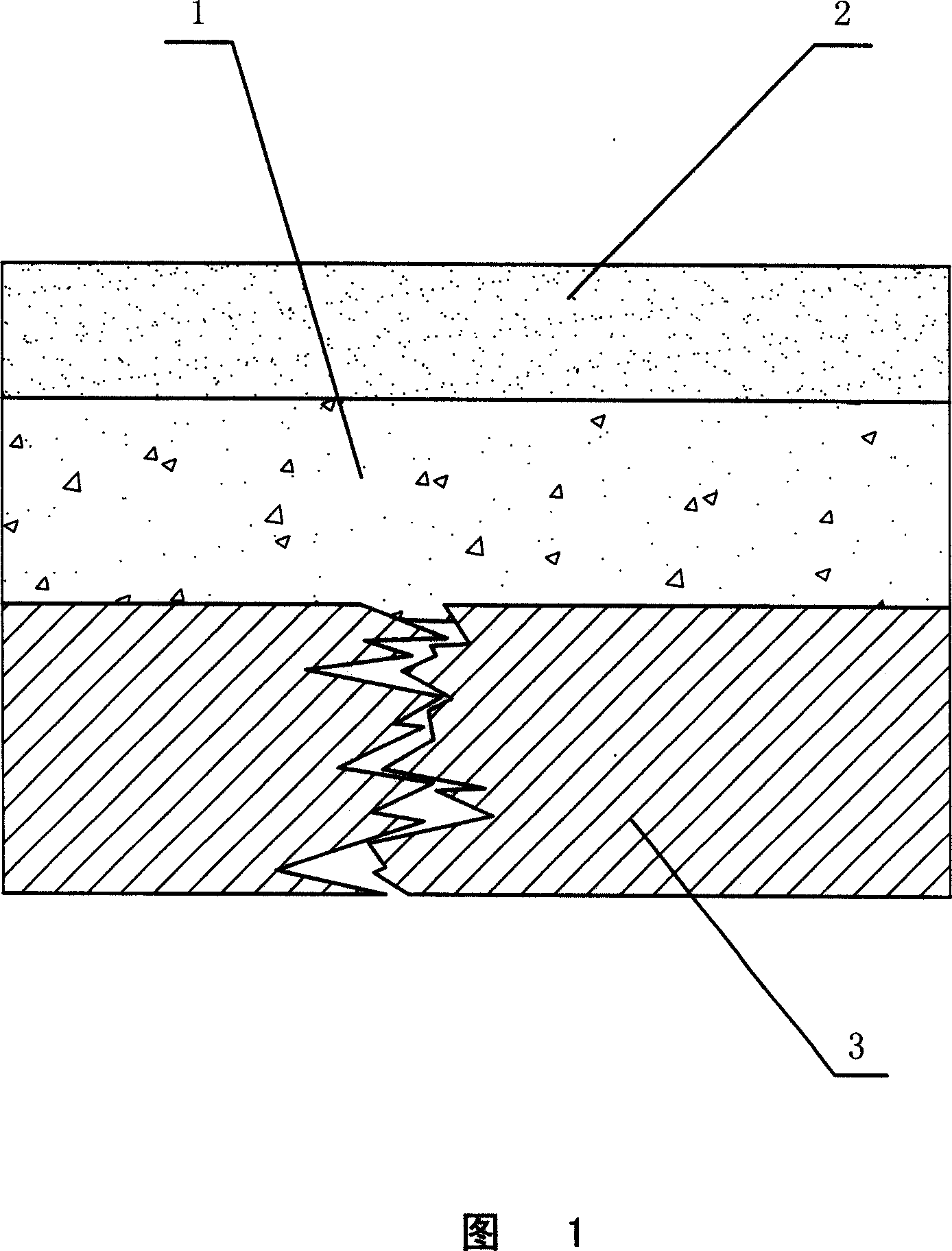

[0056] The process of on-site sealing is briefly described as follows: ① For the metal bonding surface, use 500 mesh metallographic sandpaper to polish, and then use acetone to clean the surface; for electrical ceramics, do not use sandpaper to polish the surface of electrical ceramics, and only use alcohol or acetone to wipe; ② The base material and the nano-powder are uniformly mixed in a certain proportion for later use; ③ The above mixture and the curing agent are uniformly mixed in a certain ratio according to the curing time requirements to form a mixed material 1 for later use; ④ Use a special tool to evenly coat the mixed material 1 adhesive on the blocked surface of the leakage part 3; ⑤ After the adhesive is mixed with inorganic fillers, it is easy to absorb water. Apply a layer of plugging material 2 according to the mixture of base material: curing agent = 1: 1, to prevent the bonding surface of the mixture 1 from being damp and causing the bonding material to age. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com