A method for making MEMS switch, and MEM device and its making method

An electromechanical device and device technology, which is applied to the manufacture of microelectromechanical system switches and the field of microelectromechanical devices and their manufacture, can solve the problems of scrapped switches and unsatisfactory contact points, and achieve the effects of high yield and lower industrial costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

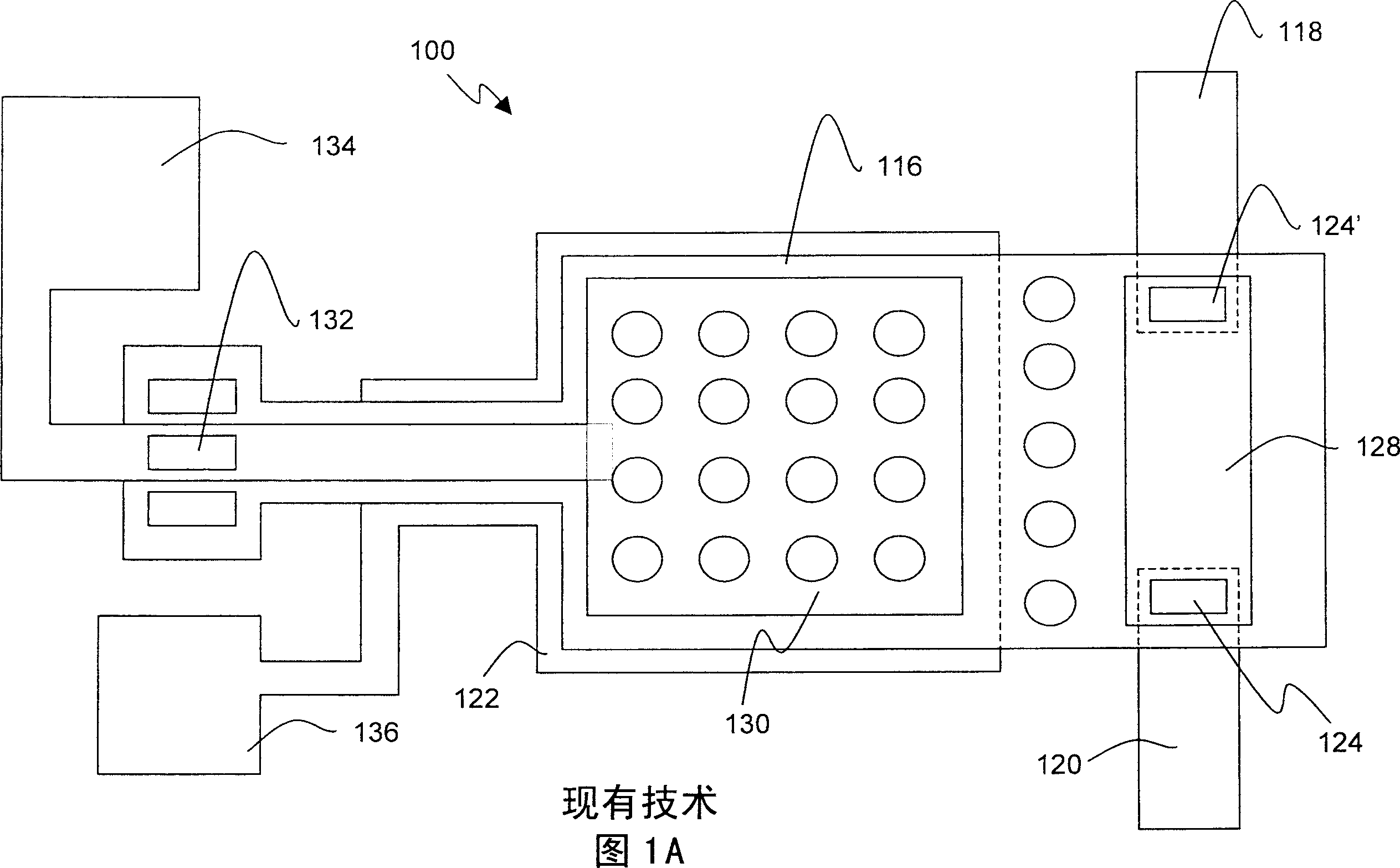

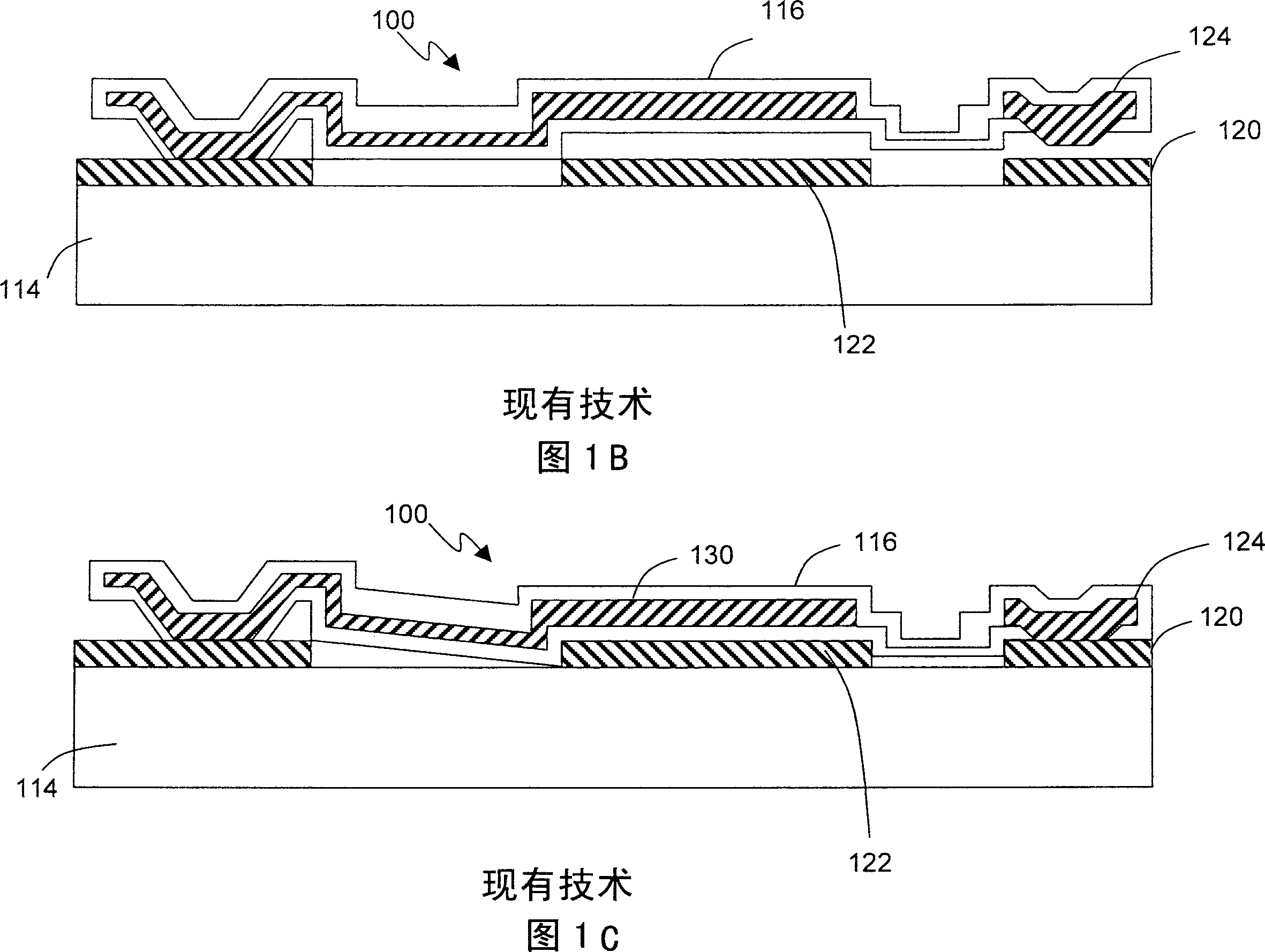

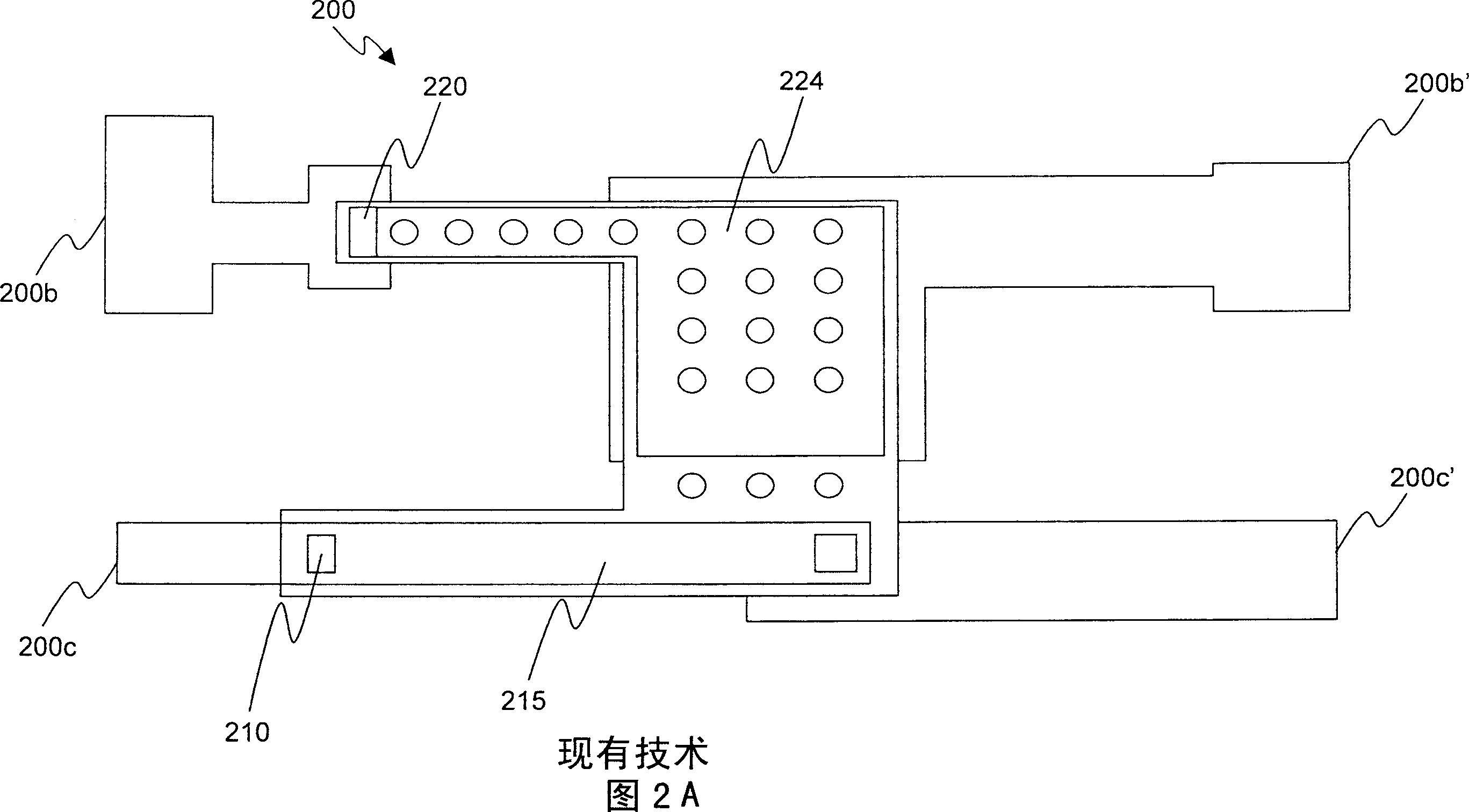

[0075] The invention relates to a production technology for improving the reliability and performance of a microelectromechanical system (MEMS) switch contact point. Specifically, the present invention relates to a planarization process for a cantilever beam, surface passivation of a substrate, and a unique design of metal dimples for making reproducible and durable contact points, as well as a method for making a common A ground plane layer and a set of contact teeth for MEMS technology. The following description, in conjunction with the accompanying drawings, enables one of ordinary skill in the art to make and use the invention and to use it in conjunction with the detailed application. Various modifications (such as use in different applications) will become apparent to those skilled in the art and apply to a wide range. The invention is therefore not limited to the aspects described, but is to be accorded the widest scope consistent with the principles and novel features...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com