Energy-saving laver drier

A drying device and seaweed technology, applied in food preservation, food preparation, food science, etc., can solve the problems of increased manufacturing cost and operation, danger, loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

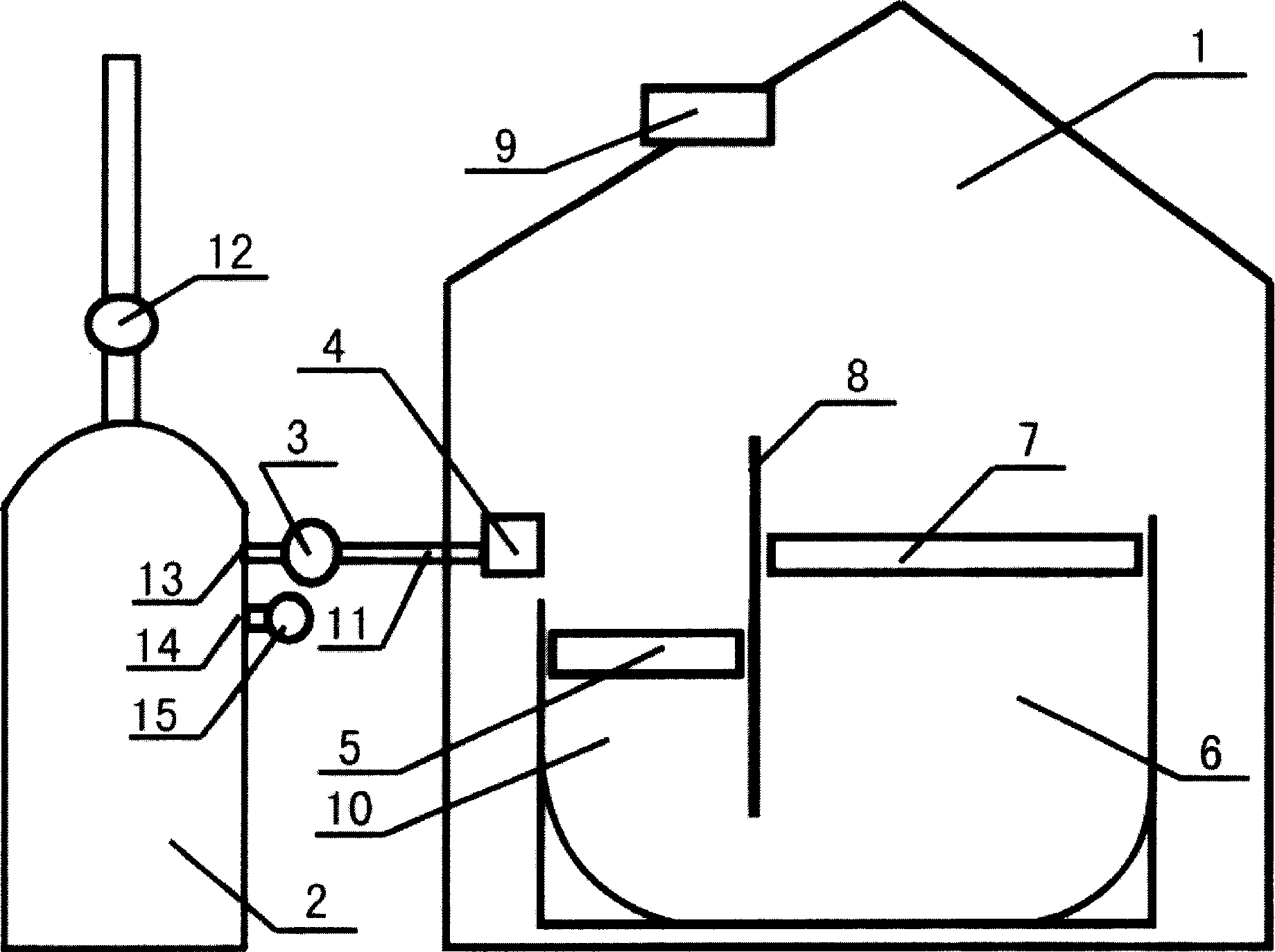

[0010] The cold air enters the hot blast stove 2 through the cold air inlet 14 and is heated by the wind blower 3 through the hot air duct 11 into the hot air distributor 4 above the main wind box 10 of the laver processing unit in the processing workshop 1, or by the cold air inlet 14. Blower 15 sends cold air into hot blast stove 2 heating gained hot air and sends into hot air distributor 4 above the main wind box 10 of laver processing unit in processing workshop 1 by hot blast pipeline 11. The main fan 5 mixes the hot air from the hot air distributor 4 with the air in the processing workshop 1 and blows it to the drying box 6 .

[0011] In order to further improve the drying quality of laver and improve the utilization rate of heat energy, a windshield 8 is set between the main air box 10 and the drying box 6, and the height of the windshield 8 should be 200mm higher than the upper surface of the highest curtain frame 7 in the drying box 6 to 2500mm.

[0012] In order to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com