Electrically catalyzed process of preparing green fuel dimethyl ether with coarse ethanol product in hydrated proton reactor

A technology of electrocatalytic hydration and crude ethanol, which is applied in the direction of isomerization to prepare ether and ether preparation, can solve the problems of consumption of fossil resources, easy corrosion of metal parts, increased fuel consumption, etc., and achieve the effect of reliable technical route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

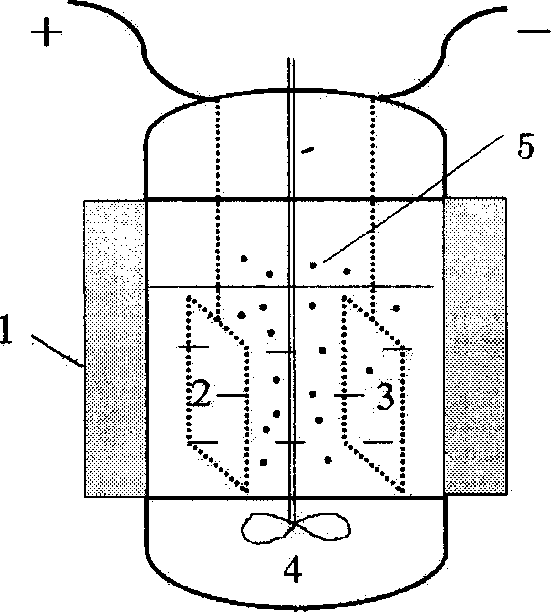

Image

Examples

Embodiment 1

[0039] HZSM-5 (SiO 2 / Al 2 o 3 =50) by NaZSM-5 and 1mol·L -1 After being exchanged four times in ammonium nitrate solution, it was obtained by roasting at 600°C in air for 6h. The Mo / HZSM-5 catalyst was prepared by an equal impregnation method. A certain amount of HZSM-5 molecular sieve was impregnated in a quantitative ammonium paramolybdate solution (pH=6), stirred at room temperature for 30min, dried at 120°C for 10h, and air Calcined at 720°C for 8 hours to obtain Mo / HZSM-5 samples with desired Mo weight percentages of 1, 2, and 5.

Embodiment 2

[0041] Mix ZSM-5 (Si / Al=29, pore average diameter 0.60nm), alumina and Pd salt solution by kneading method, extrude into rods, dry and roast, and grind into 20-40 mesh particles. Catalysts with Pd mass fractions of 0.1%, 0.2%, 0.3%, 0.4%, and 0.5% were obtained.

Embodiment 3

[0043] Catalysts A and B prepared in Examples 1 and 2 were used to react in an electrocatalytic hydrated proton device. Catalyst loading: 1g. After the catalyst is loaded, 10L of 50% ethanol is added, the air is evacuated with an inert gas, the temperature is raised to 100° C. to start the reaction, and voltage is applied to the electrodes. The reaction pressure is 0.4MPa. Equilibrium was reached after 2 hours of reaction, and samples were taken for analysis. Product analysis was carried out by HP 6890D gas chromatograph, and ethanol, dimethyl ether and by-products were analyzed by hydrogen flame ionization detector and Porapak-N chromatographic column. The results are shown in Table 1. The resulting product was separated by compression to obtain dimethyl ether.

[0044] The reaction performance of table 1 bifunctional catalyst

[0045] catalyst

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com