Method of and device for setting carbon, temperature and oxygen detecting probe in steel making converter

A steel-making converter and feeding method technology, applied in the manufacture of converters, etc., can solve the problems of lack of space and place for sub-gun equipment, large space for sub-gun equipment, high investment, maintenance and use costs of sub-gun equipment, Achieve the effects of reducing labor costs, low maintenance costs, and shortening the smelting cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

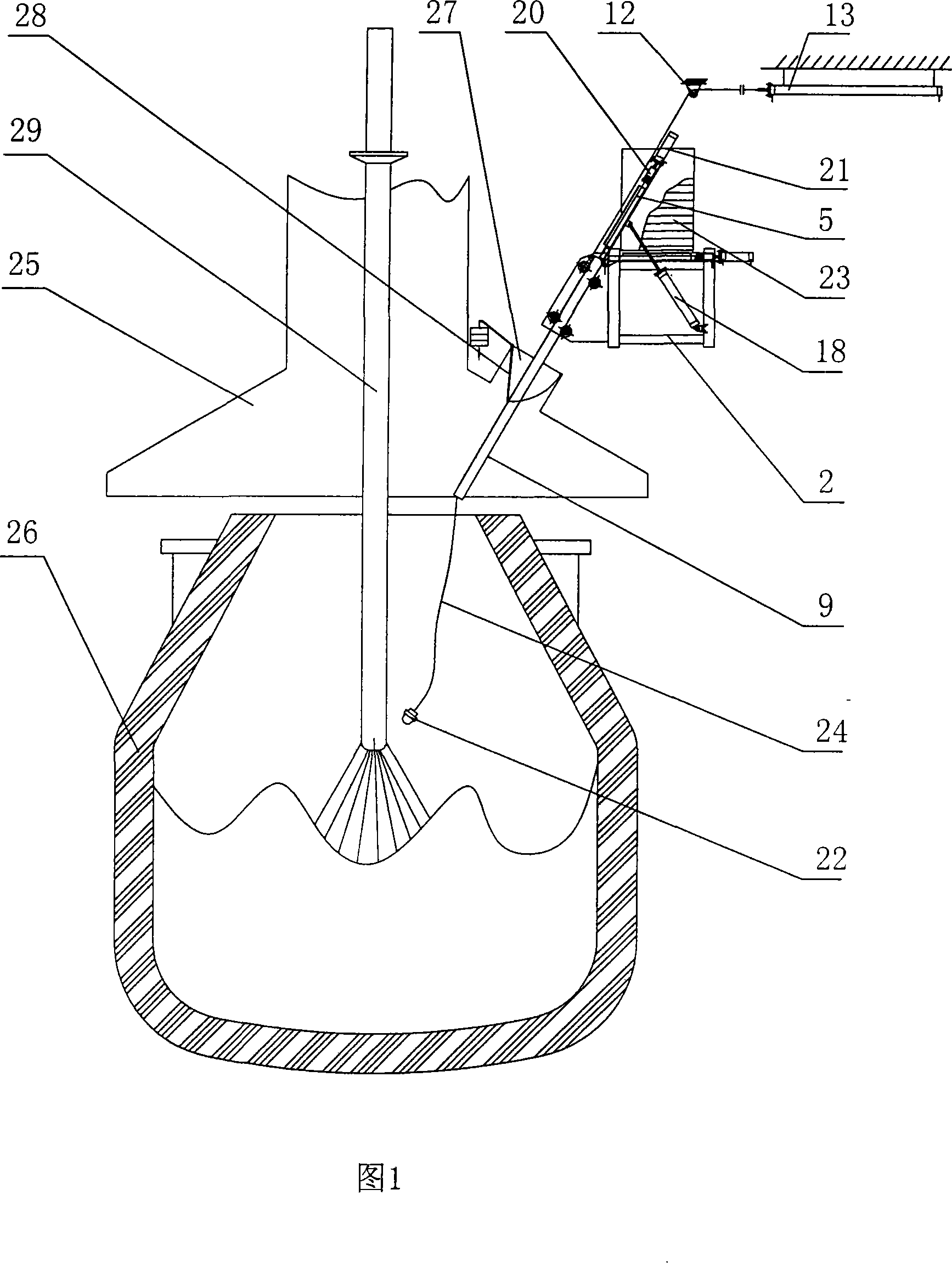

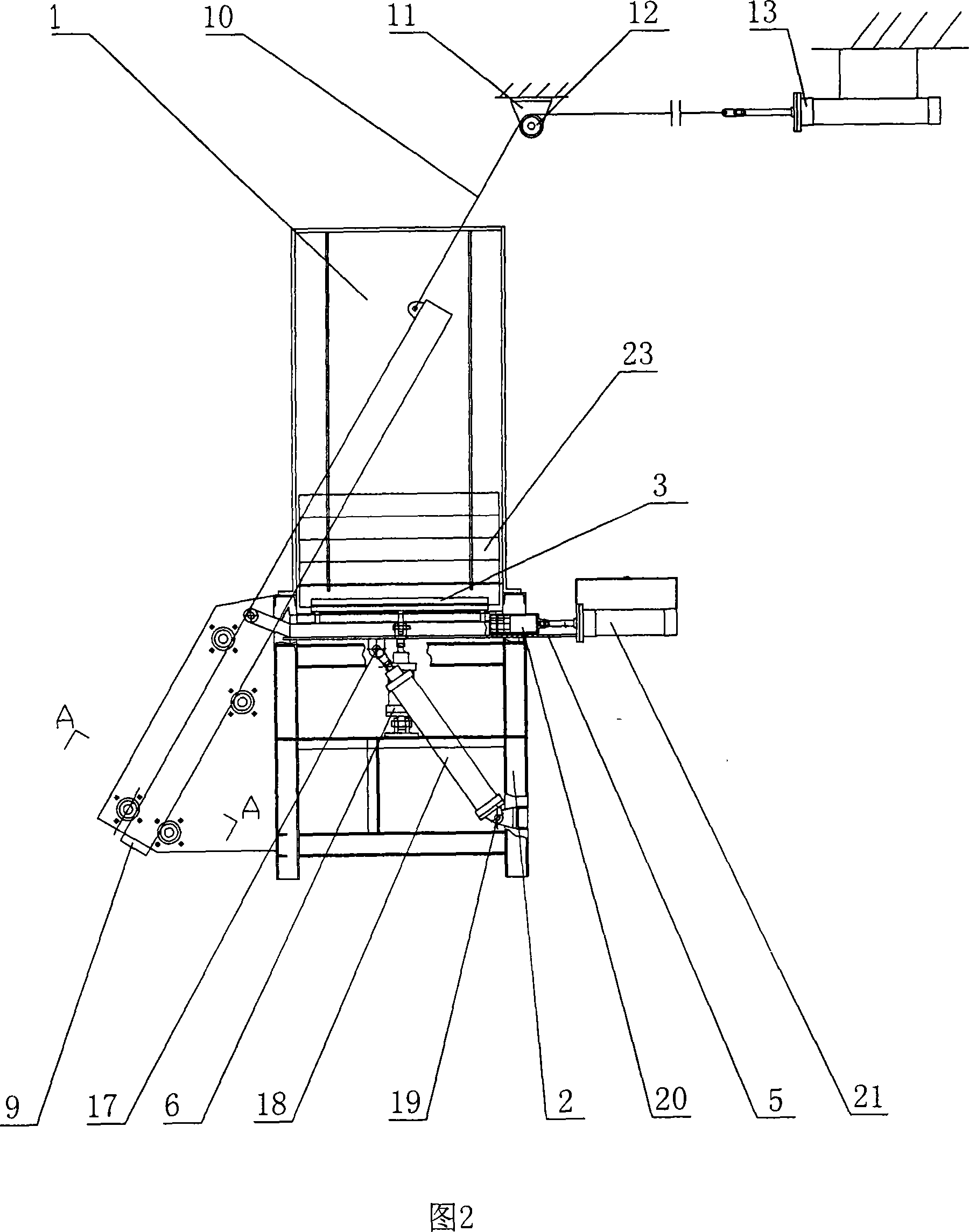

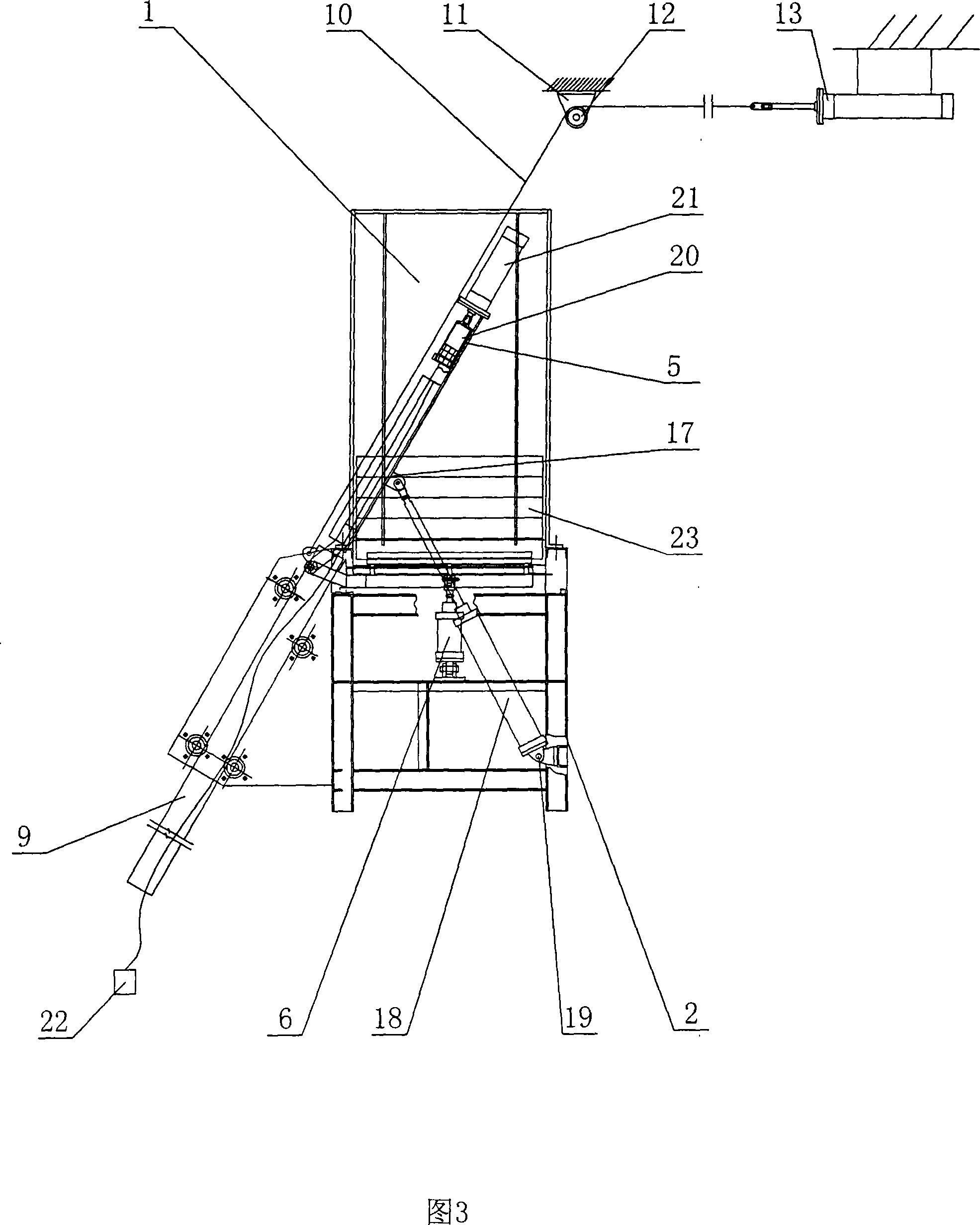

[0025] Shown in the figure is a medium and small steelmaking converter 26, the top of its sealed smoke hood 25 is only provided with an oxygen lance 29, there is no space for arranging sub-lances, and the side wall of the sealed smoke hood 25 is provided with a feeding pipe 27, The inlet of the feeding pipeline 27 is designed with an automatically resettable elastic bumper 28 , and the automatic delivery device for the carbon, temperature and oxygen detection probe of the steelmaking converter of the present invention is installed on the oblique upper side of the feeding pipeline 27 correspondingly.

[0026] The automatic dispensing device includes a frame 2 for fixing various components. A probe bin 1 with an open lower end is installed on the frame 2. A row of cylindrical probe paper tubes 23 are horizontally arranged in the probe bin 1 from bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com