Engine with breather apparatus

A ventilation device and engine technology, which is applied to engine components, combustion engines, machines/engines, etc., can solve the problems of difficult configuration space, lack of heating effect, and inability to obtain heating, and achieve generalization and easy installation operations. , the effect of reducing heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

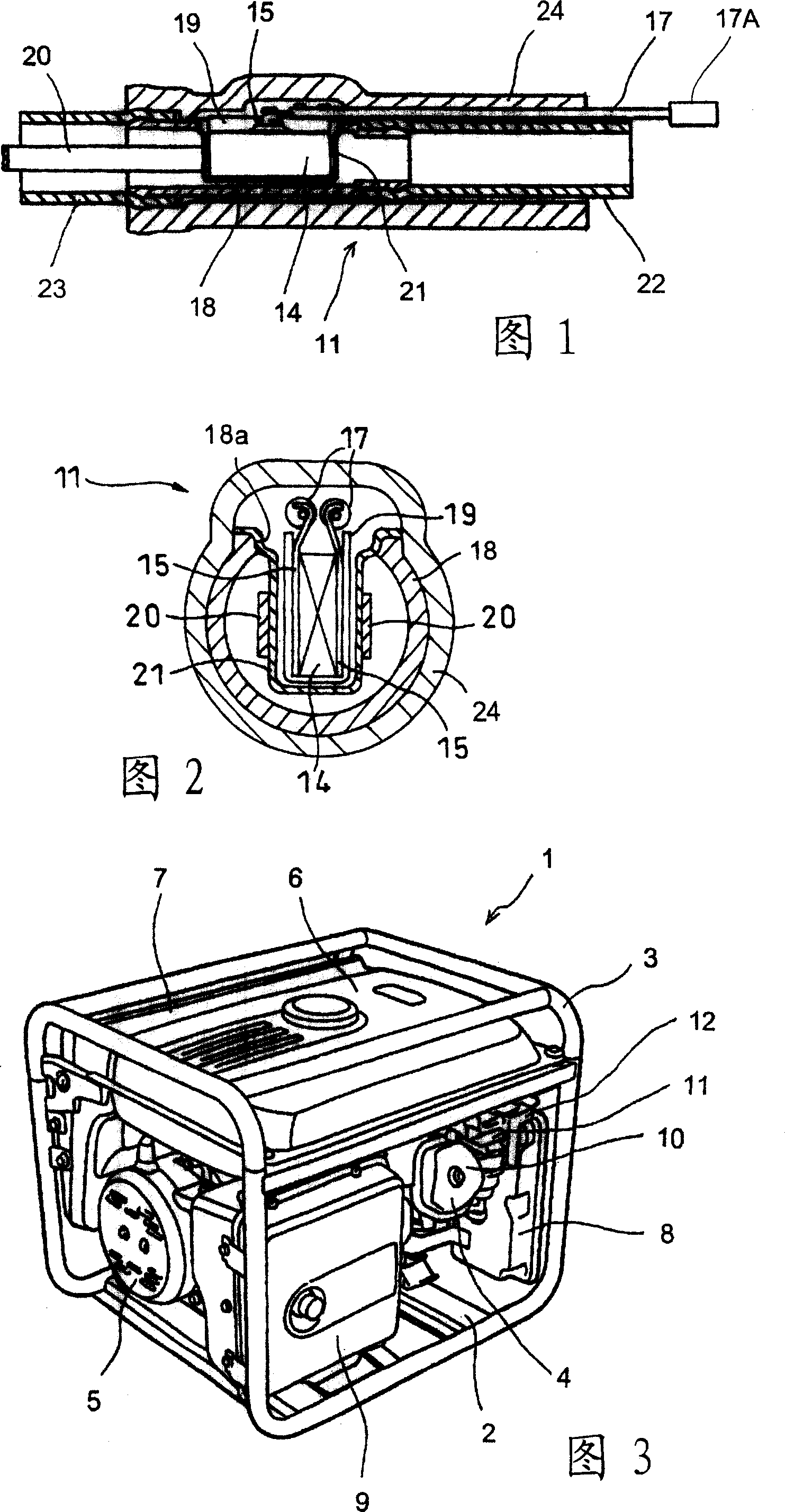

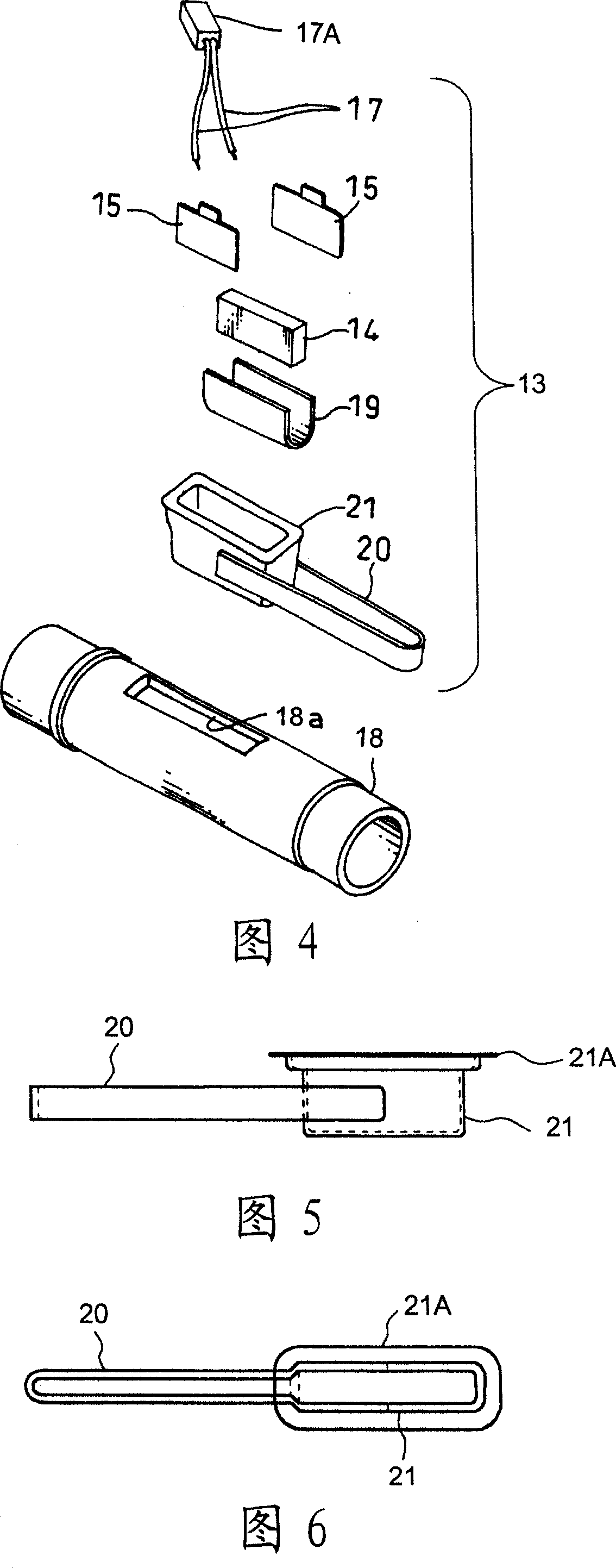

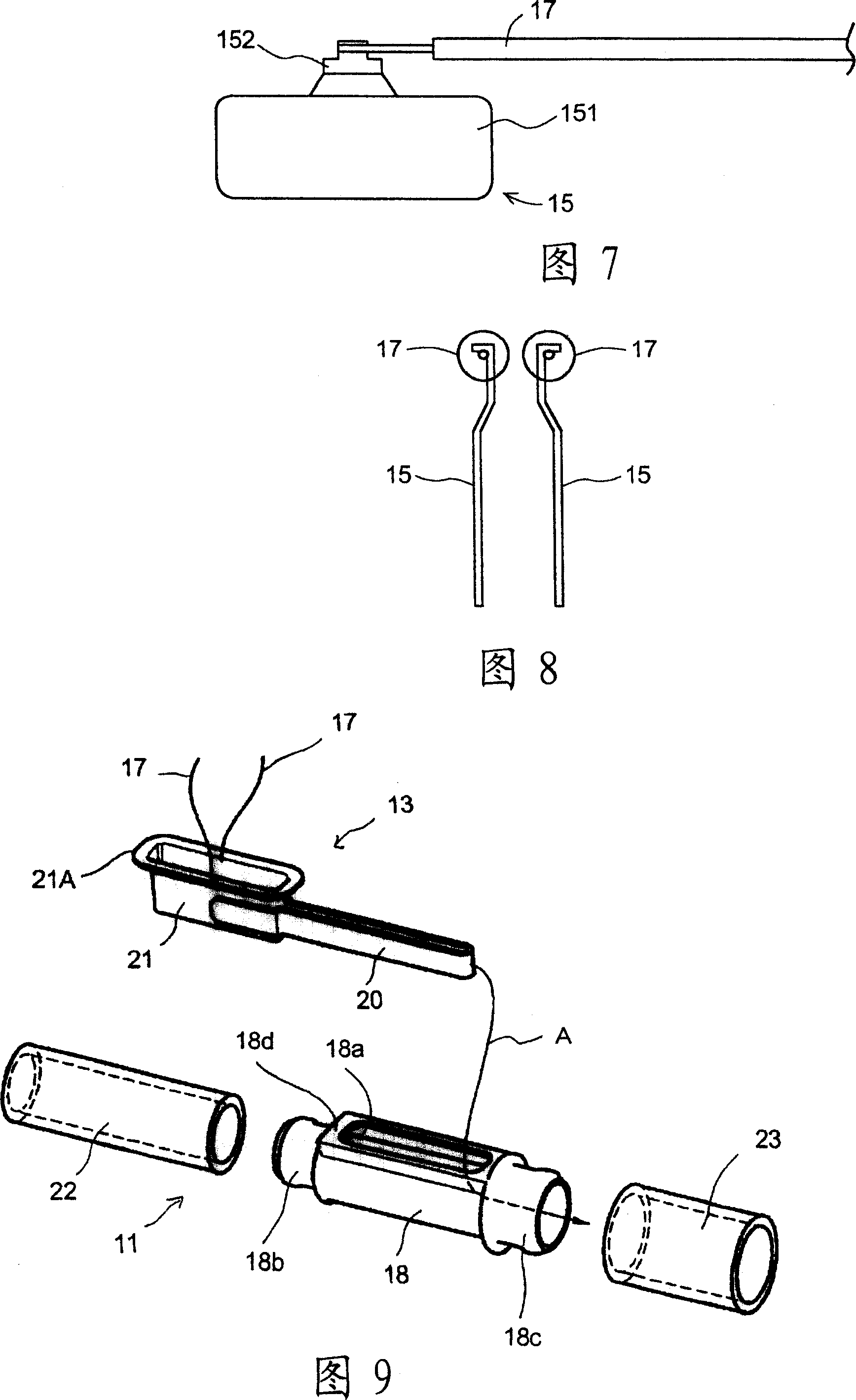

[0042] One embodiment of the present invention will be described in detail below with reference to the drawings. 3 is a perspective view of an engine generator driven by an engine with a breather device according to an embodiment of the present invention. The generator 1 has an engine 4 and a generator main body 5 accommodated at the bottom of a space formed by a bottom plate 2 and a tubular frame 3 . A fuel tank 6 is provided above the engine 4 and the generator main body 5 , and an operation panel 7 is arranged behind the fuel tank 6 . An air cleaner 8 and a muffler 9 are arranged adjacent to the engine 4 . A breather pipe 11 connecting the cylinder head cover 10 of the engine 4 and the air cleaner 8 is provided. The breather pipe 11 passes through a support portion (choke stay) of a chock assembly 12 , and one end of the breather pipe 11 is inserted into a hole formed in the cylinder head cover 10 , and the other end is introduced into the air cleaner 8 inside the housin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com