Copper/zinc/silicon alloy, use and production thereof

An alloy, cu-zn-si technology, applied in the field of copper-zinc-silicon alloys, can solve the problems of uneven material, mechanical properties changes, expensive and other problems, and achieve the effect of low corrosion rate and high corrosion resistance

Active Publication Date: 2007-08-22

DIEHL METAL STIFTUNG & CO KG

View PDF3 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This oxide scale adheres only loosely to the metal and can be easily peeled off, and is distributed throughout the production facility, with the result that these are disturbingly contaminated

Cleaning the production equipment is very expensive and laborious, resulting in high production costs

Another disadvantage of the currently known Cu-Zn-Si alloys is that the mechanical properties of the material vary in the direction of the long workpiece due to the inhomogeneity of the material

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0020] An embodiment will be explained in more detail with reference to the drawings and the following description. In this attached drawing:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

A Cu-Zn-Si alloy includes, in % by weight, 70 to 80% of copper, 1 to 5% of silicon, 0.0001 to 0.5% of boron, up to 0.2% of phosphorus and / or up to 0.2% of arsenic, a remainder of zinc, plus inevitable impurities. Products using the alloy and processes for producing the alloy are also provided. The alloy is distinguished by an improved resistance to oxidation and by uniform mechanical properties.

Description

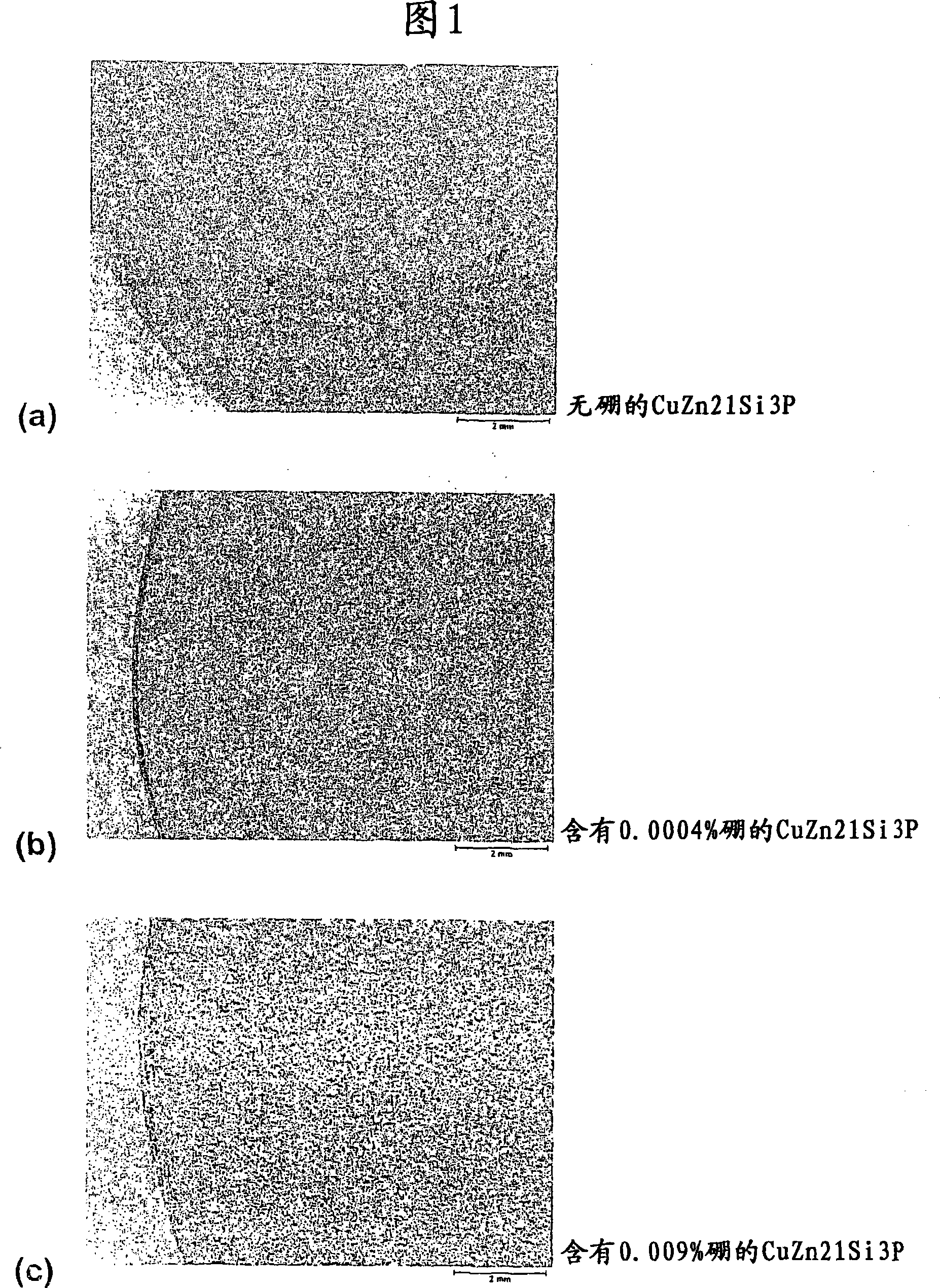

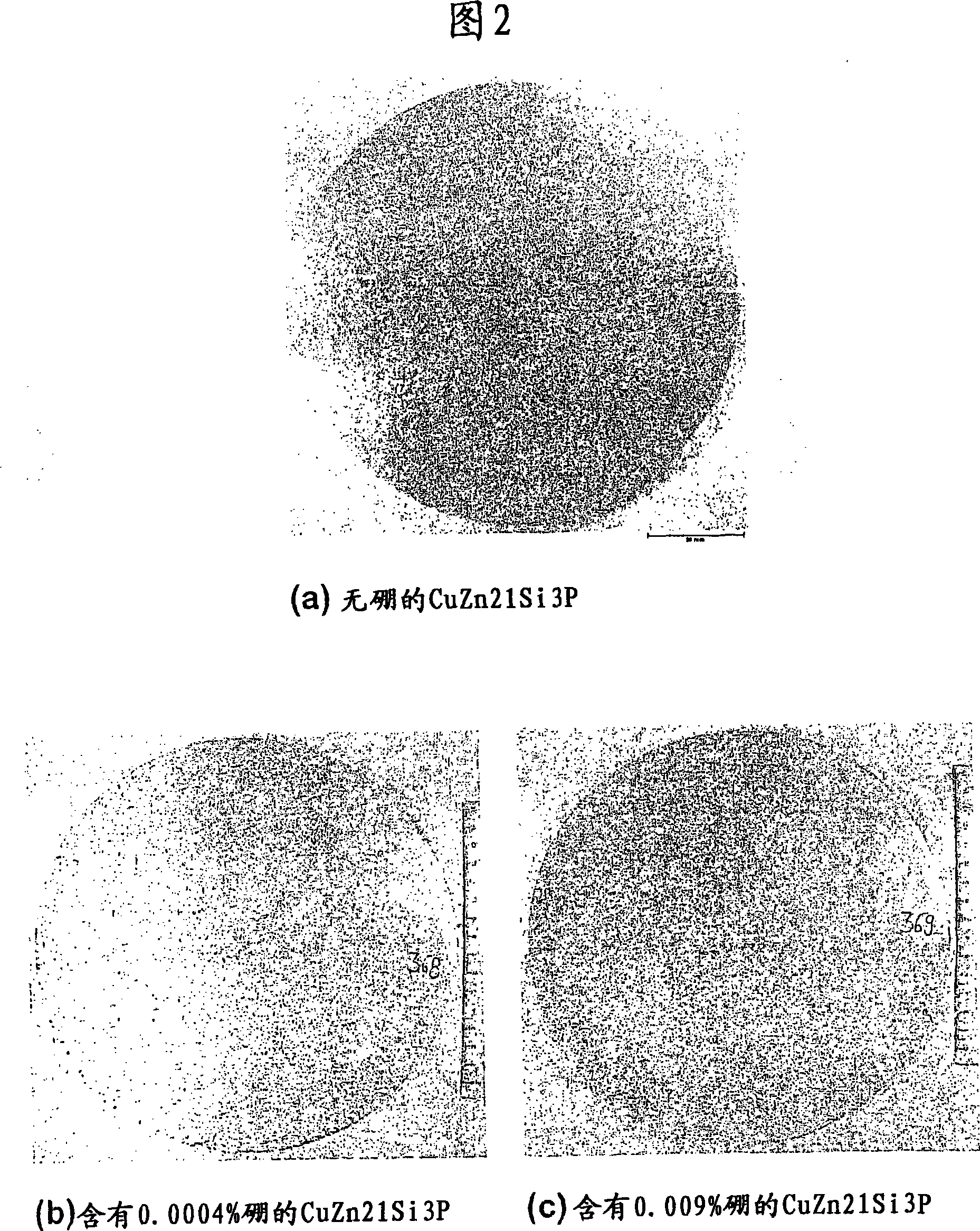

technical field [0001] The present invention relates to copper-zinc-silicon alloys and the use and preparation of such copper-zinc-silicon alloys. Background technique [0002] The immediate requirements for copper-zinc-silicon alloys are that they are dezincification resistant and machinable. To date, good machinability of such brass alloys has been achieved by the addition of lead, as described, for example, in EP 1 045 041 A1. Recently, however, lead-free brass alloys having good machinability have also been developed, as described, for example, in EP 1 038 981 A1 and DE 103 08 778 B3. Both lead-free and lead-containing Cu-Zn-Si alloys tend to oxidize and form scale layers at temperatures between 300°C and 800°C. This scale layer adheres only loosely to the metal and can be easily peeled off and is distributed over the entire production plant, with the result that these are disturbingly contaminated. Cleaning the production equipment is very expensive and laborious, re...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C9/04

CPCC22C9/04C22C9/10

Inventor H·施特罗布尔K·施瓦姆H·迈尔N·加格U·雷克塞尔K·马斯塔勒

Owner DIEHL METAL STIFTUNG & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com