Large-flow immediately-heating water-drinking machine

A water dispenser, instant heating technology, applied in the directions of fluid heaters, water heaters, beverage preparation devices, etc., can solve the problems of increased structural complexity, complex product structure, decreased reliability, etc., to reduce the possibility of scaling good heat transfer effect, obvious energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

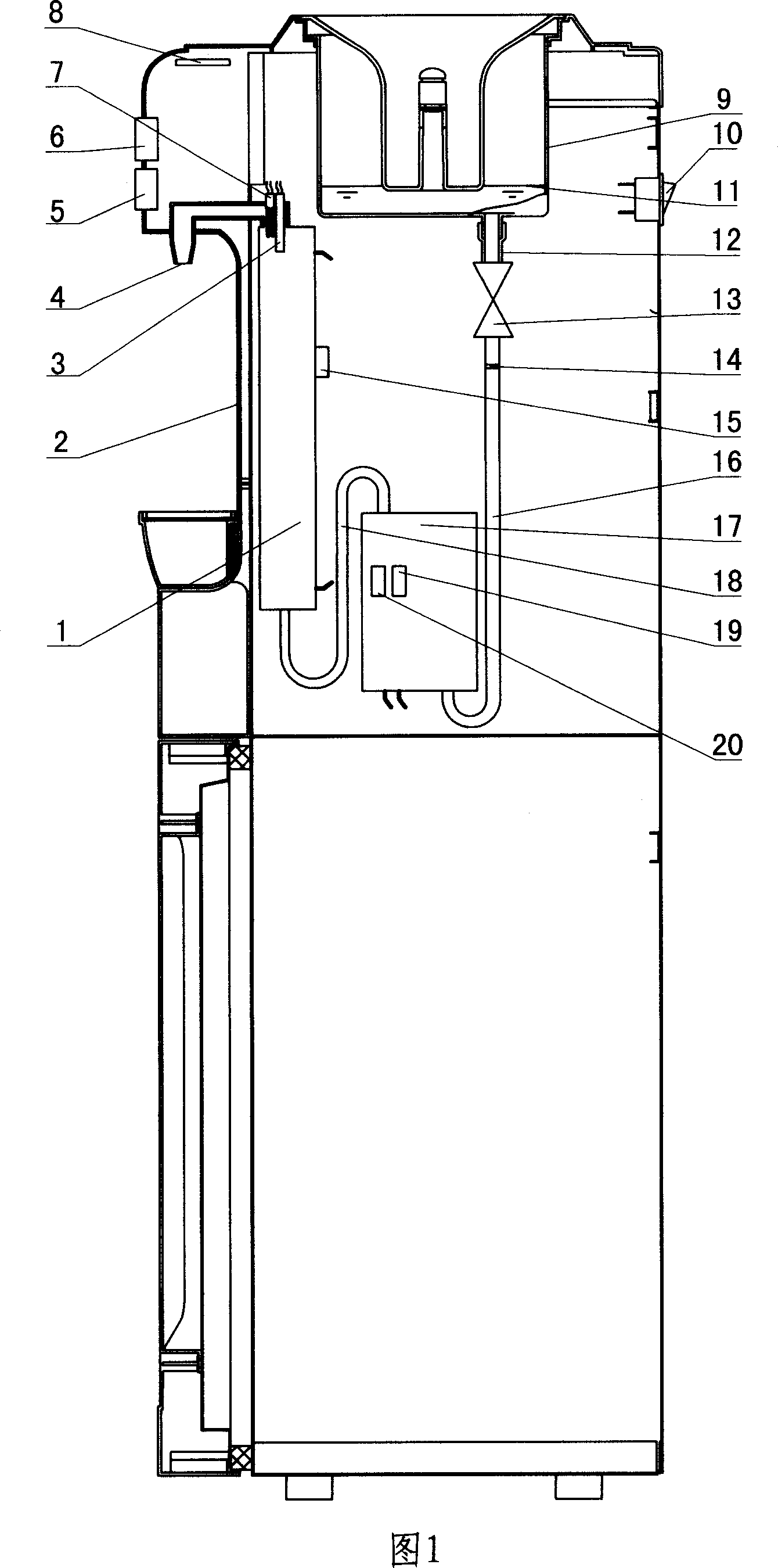

[0046] Embodiment 1: As shown in FIG. 1, the large-flow instant water dispenser of the present invention includes a water dispenser bucket 9, and on the pipeline between the water outlet 12 of the water dispenser bucket 9 and the water outlet 4 of the water dispenser, connect There are valves 13, throttling devices, pipeline electric heaters 1 and container electric heaters 17. The pipeline electric heater 1 is installed vertically inside the water dispenser housing 2, the water outlet is on the top, and the water inlet is on the bottom. The drinking water is heated to the power above the set temperature (for example, 85°C); the inner diameter of the water pipe in the pipeline electric heater 1 is not less than 15 mm, and its water outlet is connected to the water outlet 4 of the water dispenser; the valve 13 can be It is manual or automatic. Considering the convenience of automatic control, a normally closed solenoid valve is preferred; the water level 11 in the water bucket ...

Embodiment 2

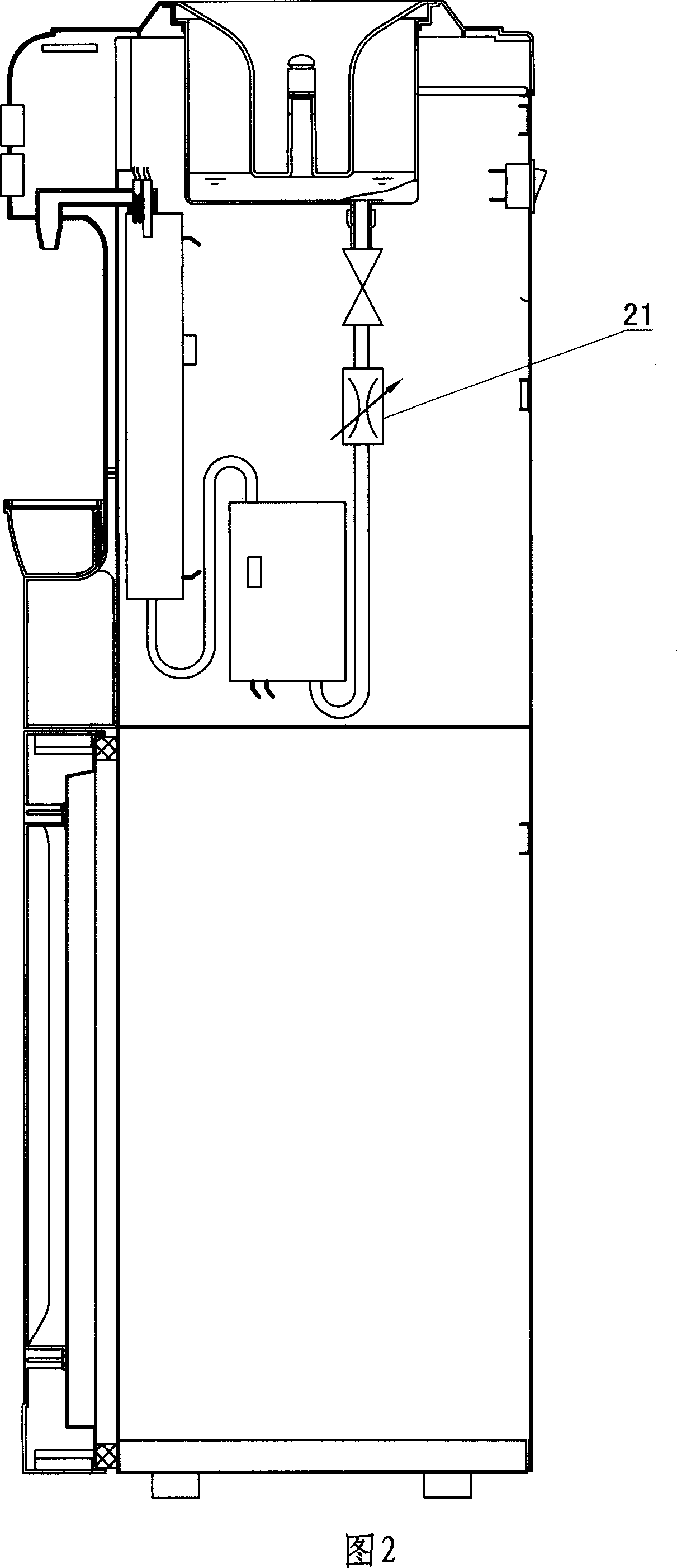

[0051] Embodiment 2: As shown in FIG. 1 and FIG. 2 , the throttling device in this embodiment is an adjustable throttle valve 21 that can adjust the flow rate, and other parts are the same as in Embodiment 1. The throttling valve 21 matches the power of the pipeline electric heater 1, and the outlet water temperature can reach above 95° C. at the minimum flow rate, and above 70° C. at the maximum flow rate. It is convenient for users to obtain hot water of different temperatures according to their needs.

Embodiment 3

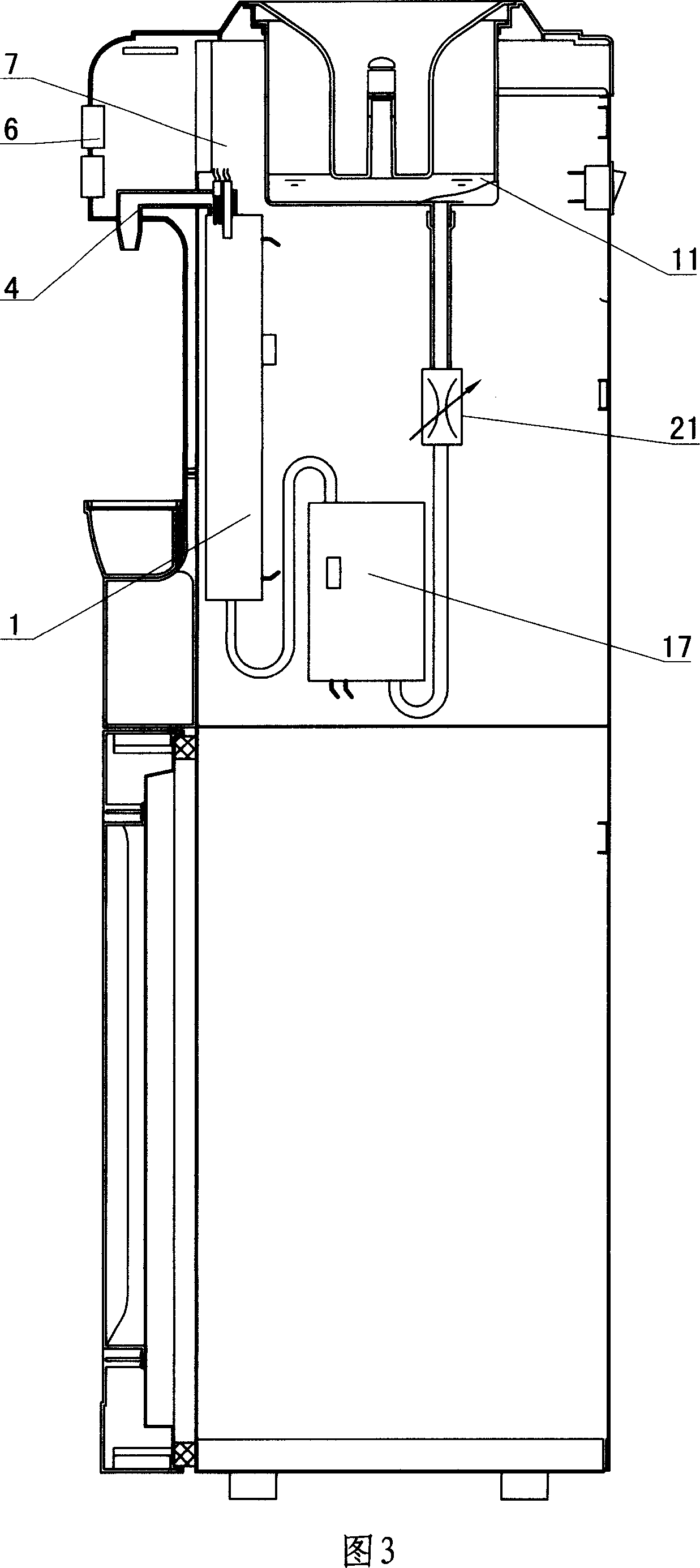

[0052] Embodiment 3: As shown in FIG. 1 and FIG. 3, this embodiment is a simplified structure of the present invention. On the pipeline between the water outlet 12 of the bucket and the water outlet 4 of the water dispenser, no valve is provided, and the housing of the water dispenser There is no thermostat on the body. In this case, the water level 11 in the bucket should be slightly lower than the highest position of the outlet pipeline of the pipeline electric heater 1. When the pipeline electric heater 1 is not powered on, because the water level in the bucket is lower than the highest position of the outlet pipeline of the pipeline electric heater 1, no water will come out from the hot water outlet 4 of the water dispenser; after the pipeline electric heater 1 is powered on, the When the water is heated and expands, the water level will be higher than the water level in the water bucket of the water dispenser, and hot water will start to come out from the 4 hot water outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com