Cloth-plastic hot-water bag and processing method

A hot water bottle, cloth plastic technology, applied in the processing of cloth hot water bottle, cloth hot water bottle, medical care and general life heating fields, can solve the problems of discomfort, short service life, easy to break and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

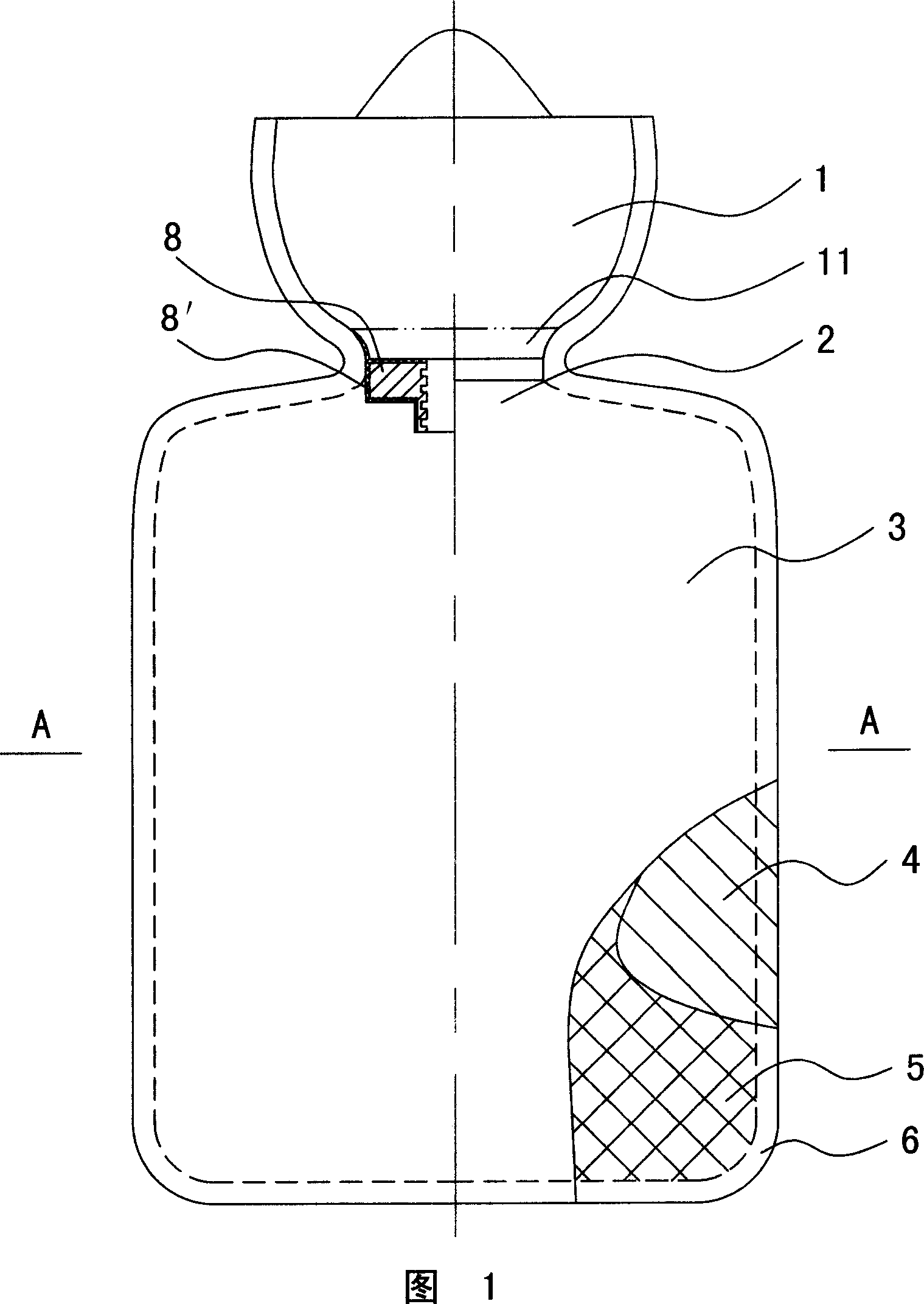

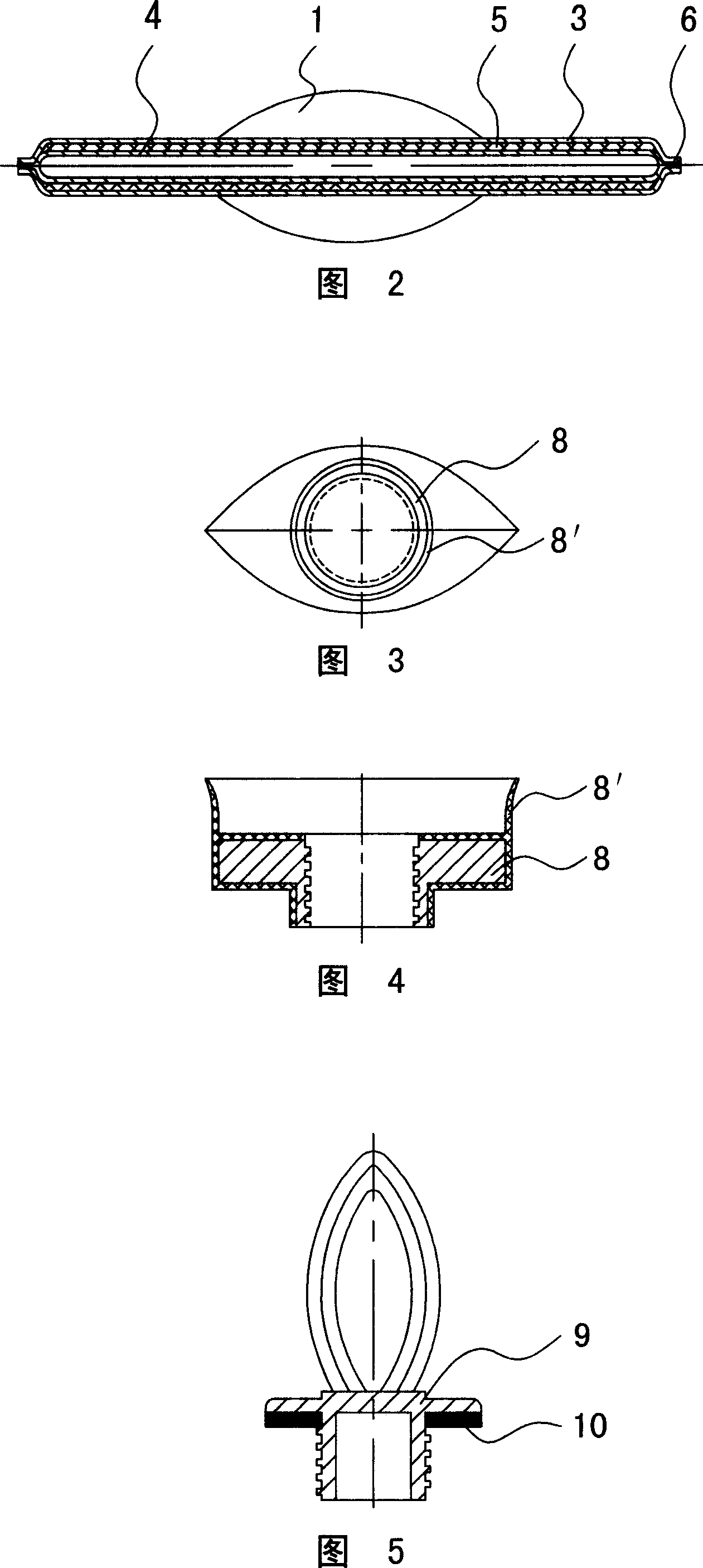

[0024] The present invention relates to a cloth-plastic hot water bag and a processing method thereof. The cloth-plastic hot water bag is composed of a bag body, a bag opening 1 and a bag plug 2. As shown in FIGS. 1-5 , the bag body has an inner layer 4, an outer layer 3 and a thermal insulation Layer 5 is composed of three layers, and there is an adhesive edge 6 on the edge of the bag body. The bag plug is composed of a threaded plug seat 8 and a threaded plug cover 9. Its main technical feature is that the outer wall of the threaded plug seat 8 has a composite Layer 8', as shown in Figure 1 and Figure 4, and the threaded plug cap 9 has a sealing gasket 10, as shown in Figure 5. The inner layer 4 is made of polyvinyl chloride film or other similar materials, and the outer layer is made of polyester cloth lamination, which has high strength and can be printed with various patterns, so that the hot water bag has a beautiful appearance. And heat insulation layer 5 is installed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com