Electronic device, dielectric ceramic composition and the production method

A technology of ceramic composition and electronic components, which is applied in the parts of fixed capacitors, electrical components, dielectrics of fixed capacitors, etc., can solve the problems of deterioration of life under high temperature load, difficulty in thin layering, multi-layering, etc., to ensure sufficient reliability. The effect of sex, large capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

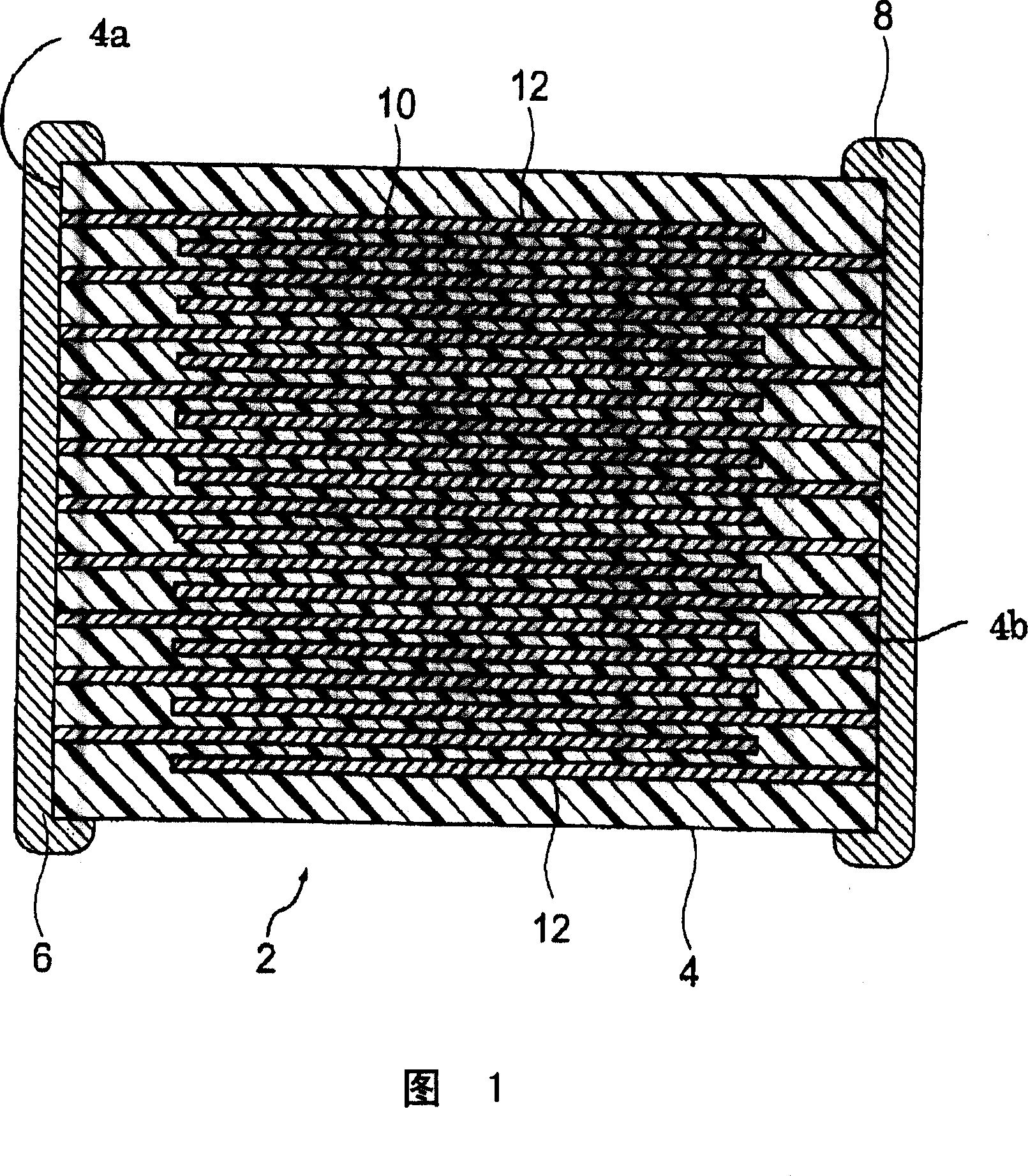

Image

Examples

Embodiment 1

[0104] First, main component raw materials and subcomponent raw materials are prepared. As the main component raw material, BaTiO with an average particle size of 0.2 μm is used 3 . As a subcomponent raw material, MgCO is used 3 (1st subcomponent), (Ba 0.6 Ca 0.4 ) SiO 3 (second subcomponent), V 2 o 5 (the third subcomponent), Y 2 o 3 (4th subcomponent), Tb 4 o 7 (the fifth subcomponent), MnCO 3 (the 6th sub-ingredient). Among them, MgCO 3 and MnCO 3 Oxides are formed upon sintering to be present in the dielectric ceramic composition in the form of MgO and MnO, respectively. (Ba 0.6 Ca 0.4 ) SiO 3 (hereinafter also referred to as BCG) was produced by the following method.

[0105] For BCG, BaCO 3 , CaCO 3 and SiO 2 BCG was produced by wet mixing with a ball mill for 16 hours, drying, and sintering in air at 1150° C., and then wet pulverizing with a ball mill for 100 hours.

[0106] Next, according to the relative 100 moles of BaTiO 3 The compositions of ...

Embodiment 2

[0155] Capacitor samples were produced in the same manner as in Example 1 except that the composition of the subcomponents was set to the composition shown in Table 2, and the same characteristic evaluation as in Example 1 was performed. The results are shown in Table 2.

[0156] Table 2

[0157]

sample

serial number

Subcomponents

**(of dielectric particles

average grain size)

/

(Main ingredient of raw material

The average particle size)

electrical characteristics

No. 4

number 5

4th and 5th

total moles

The molar ratio of

No. 1

2nd

No. 3

number 6

relative dielectric

constant

εr

Dielectric loss

tanδ

X7R Features

high temperature

load life

[h]

CR product

[μF·MΩ]

R1 conversion

R2 conv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com