Dual-roving yarn guide for drafting device of weaving machine

A drafting device and yarn guide technology, applied in spinning machines, drafting equipment, textiles and papermaking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

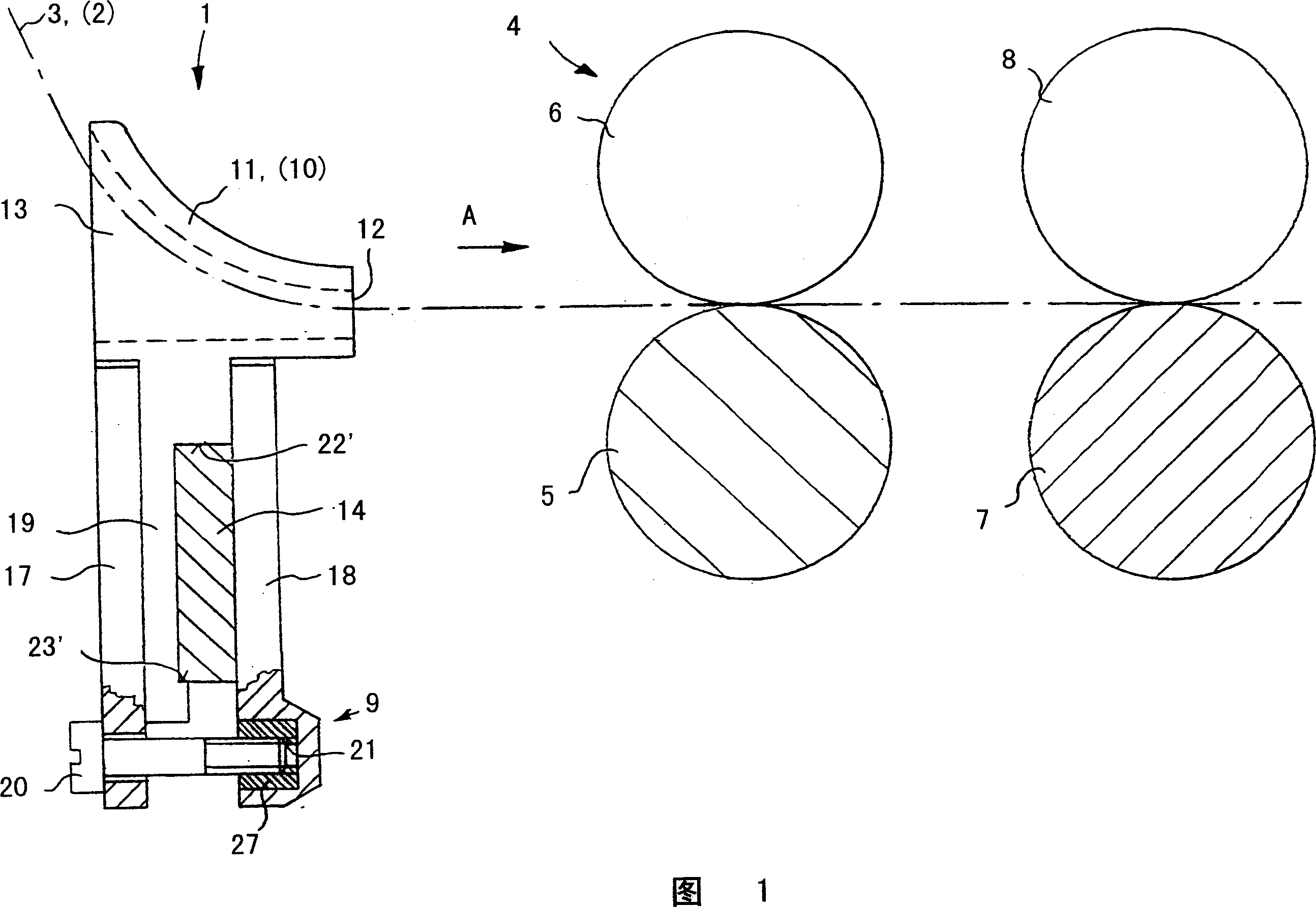

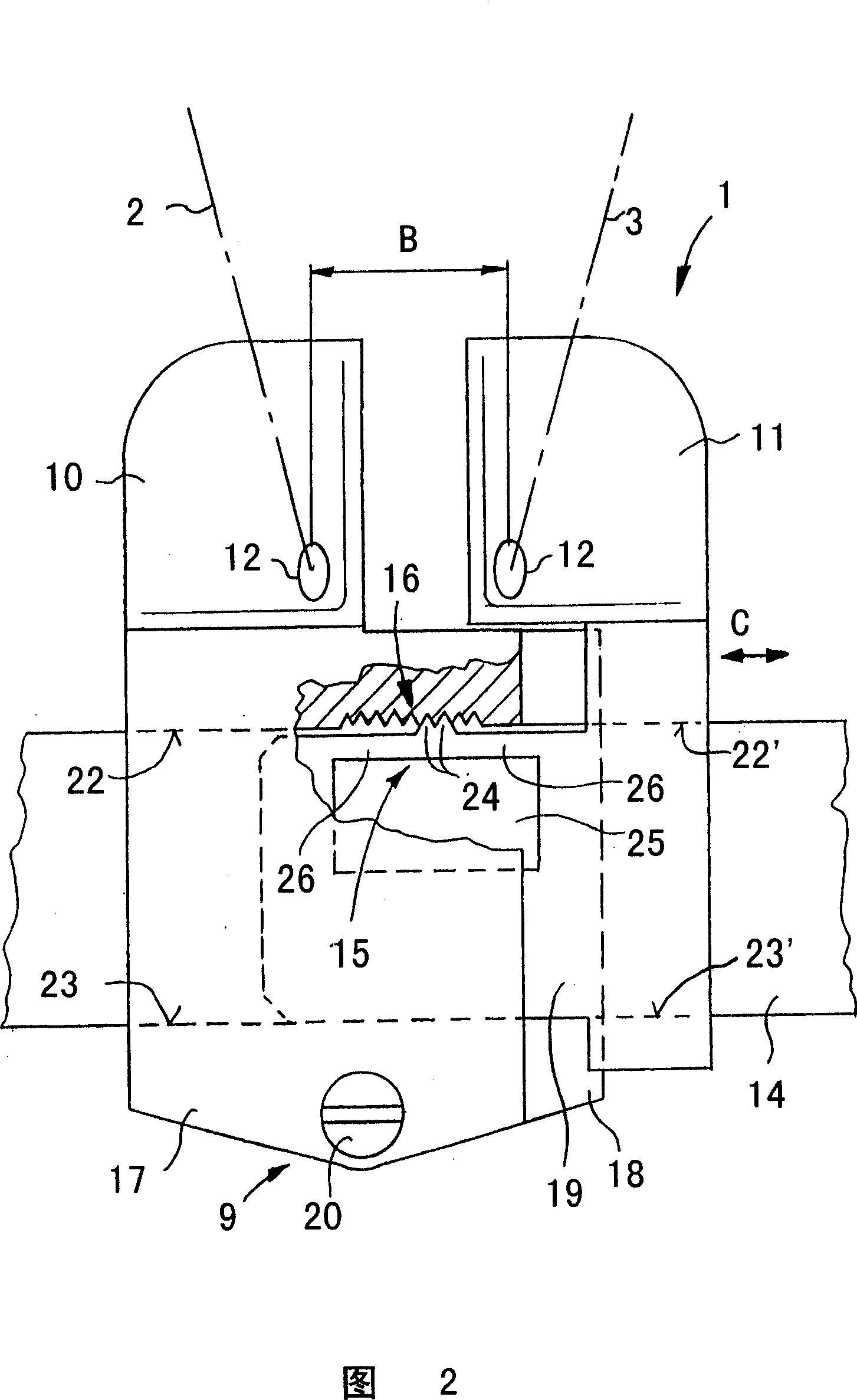

[0018] The double roving guide shown in FIGS. 1 and 2 feeds two fiber strands or rovings 2 and 3 into the drafting device 4 . The drafting device 4 consists of a number of roller pairs, of which only two roller pairs 5 , 6 and 7 , 8 are shown in FIG. 1 . Bottom rollers 5 and 7 are driven and they are under pressure from top rollers 6 and 8 respectively. In the case of the drafting device 4 of the ring spinning frame, the bottom rollers 5, 7 are designed as grooved rollers running through in the longitudinal direction of the machine. The rovings 2, 3 are fed into the drafting device 4 in the transport direction A and drawn to the desired fineness. It is provided in a manner not shown that a compression device can also be provided directly downstream of the drafting device 4 following the pair of delivery rollers, in which compression device the two rovings 2 and 3 are compressed and compacted in separate compression zones. Then the drawn fiber strands are either fed into a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com