Multi-purpose pressurized capillary electrochromatography apparatus

A capillary electrochromatography and capillary chromatographic column technology, which is applied in the field of multi-purpose pressurized capillary electrochromatography devices, can solve the problems of inflexible flow splitting mode, etc., and achieve the effect of promoting establishment and optimization and increasing flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

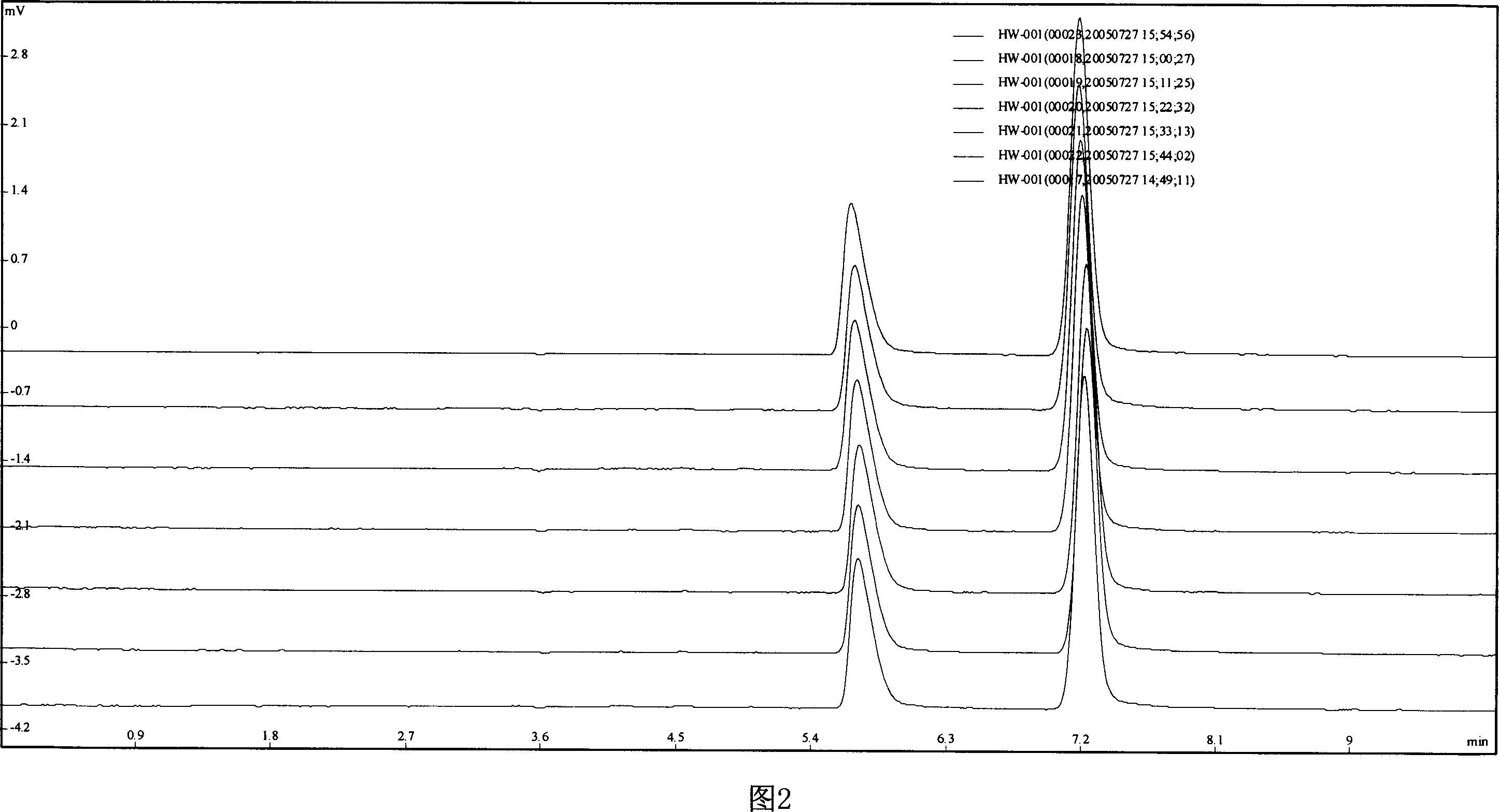

[0009] Fig. 2 is the embodiment 1 of applying the multipurpose pressurized capillary electrochromatography device of the present invention to separate aniline and benzoic acid mixed samples;

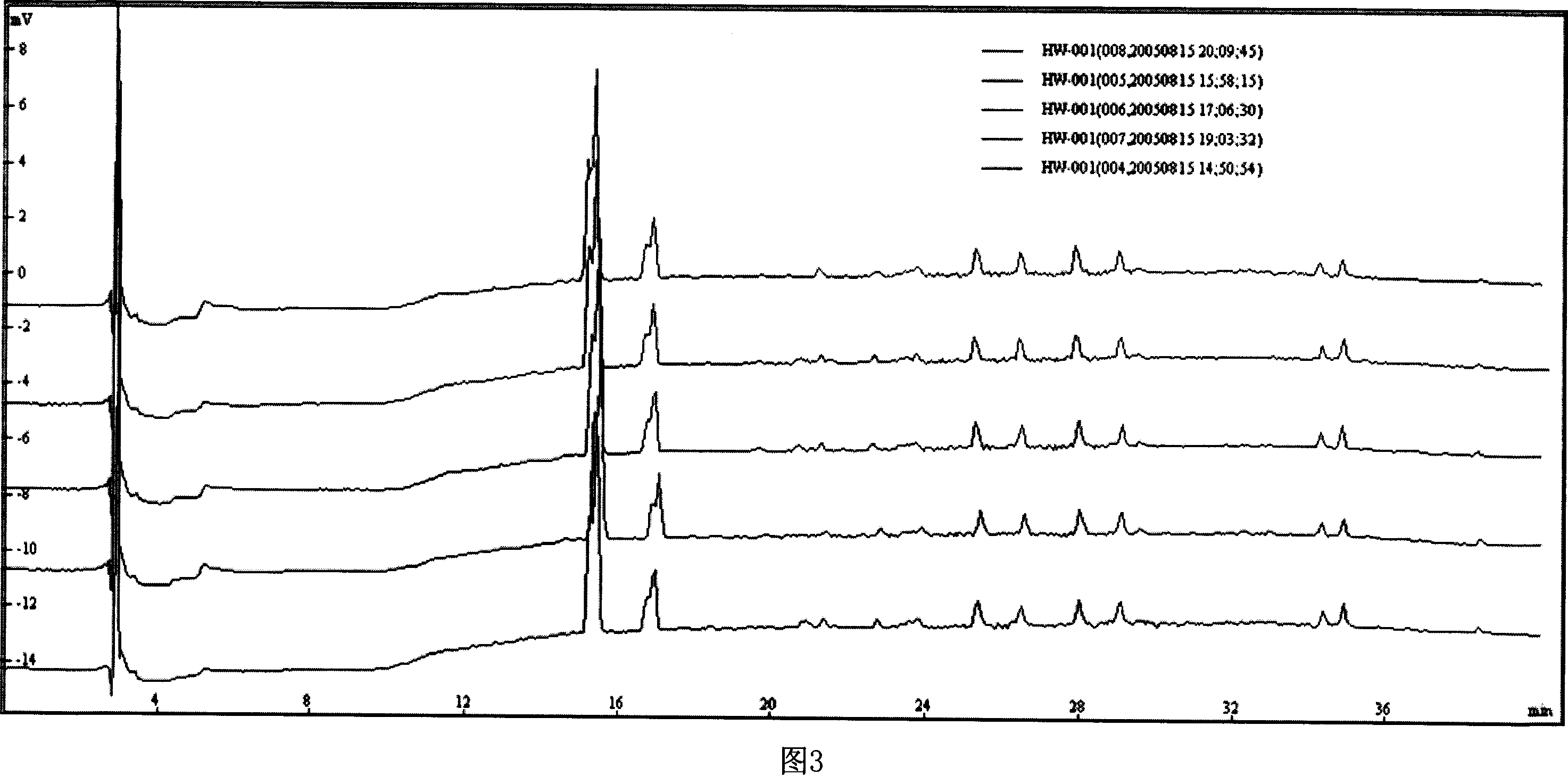

[0010] Fig. 3 is the embodiment 2 of applying the multipurpose pressurized capillary electrochromatography device of the present invention to separate ink samples.

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

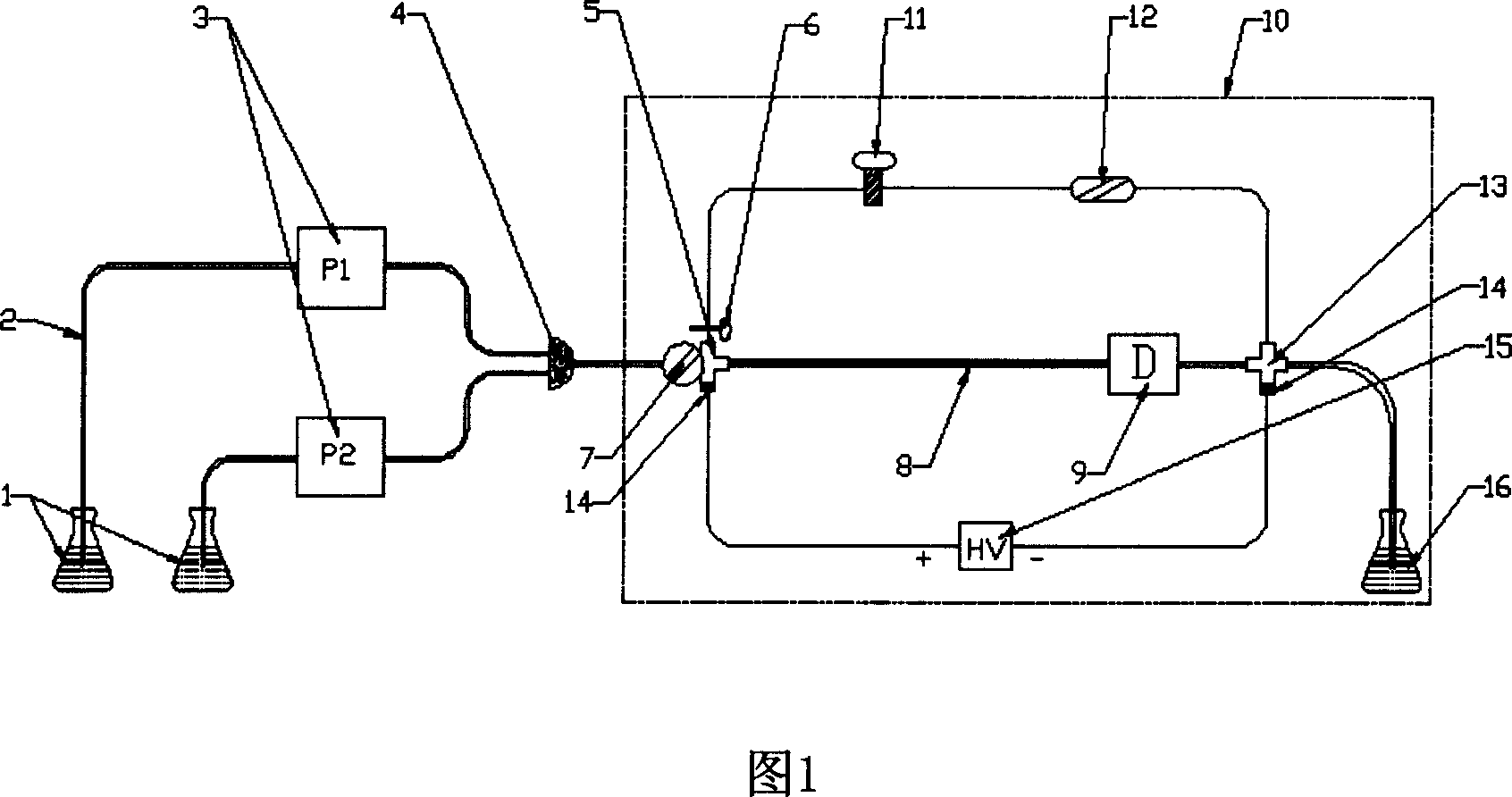

[0012] The multi-purpose pressurized capillary electrochromatography device of the present invention is shown in FIG. 1 , the suction end of the high-pressure pump 3 is passed into the mobile phase 1 through the suction pipe 2 , and its output end is connected with the mixing valve 4 . The mixing valve 4 is connected with the splitter 6 or the injection valve 7 through a connecting pipe, and enters the separation system 10 . The sample pushed by the mobile phase 1 can first pass through the...

Embodiment 2

[0019] Application of the present invention to separate ink samples

[0020] A C18 packed capillary column with an inner diameter of 150 μm, an effective column length of 30 cm, a total length of 50 cm, and a particle size of 5 μm was used to separate ink samples by piezoelectric electrochromatography. Gradient elution was adopted, and the mobile phase was A: 5% acetonitrile + 95% water + 0.05% TFA, B: 100% acetonitrile + 0.05% TFA. Detection wavelength: 214nm, applied voltage -10kV, pressure 9.4MPa.

[0021] The injection was repeated 5 times, the retention time RSD (%) of each peak was within 1%, the maximum retention time RSD (%) of each peak area was 2.5%, and the analysis accuracy of complex samples was guaranteed (Figure 3). The sample is thus finely separated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com