Drilling three-dimensional operating platform

A kind of operation platform and three-dimensional technology, applied in the direction of drilling jigs for workpieces, large fixed members, measuring/indicating equipment, etc., can solve the problems of complex angle adjustment, high production cost, and long preparation cycle, and achieve high precision of workpieces , making simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

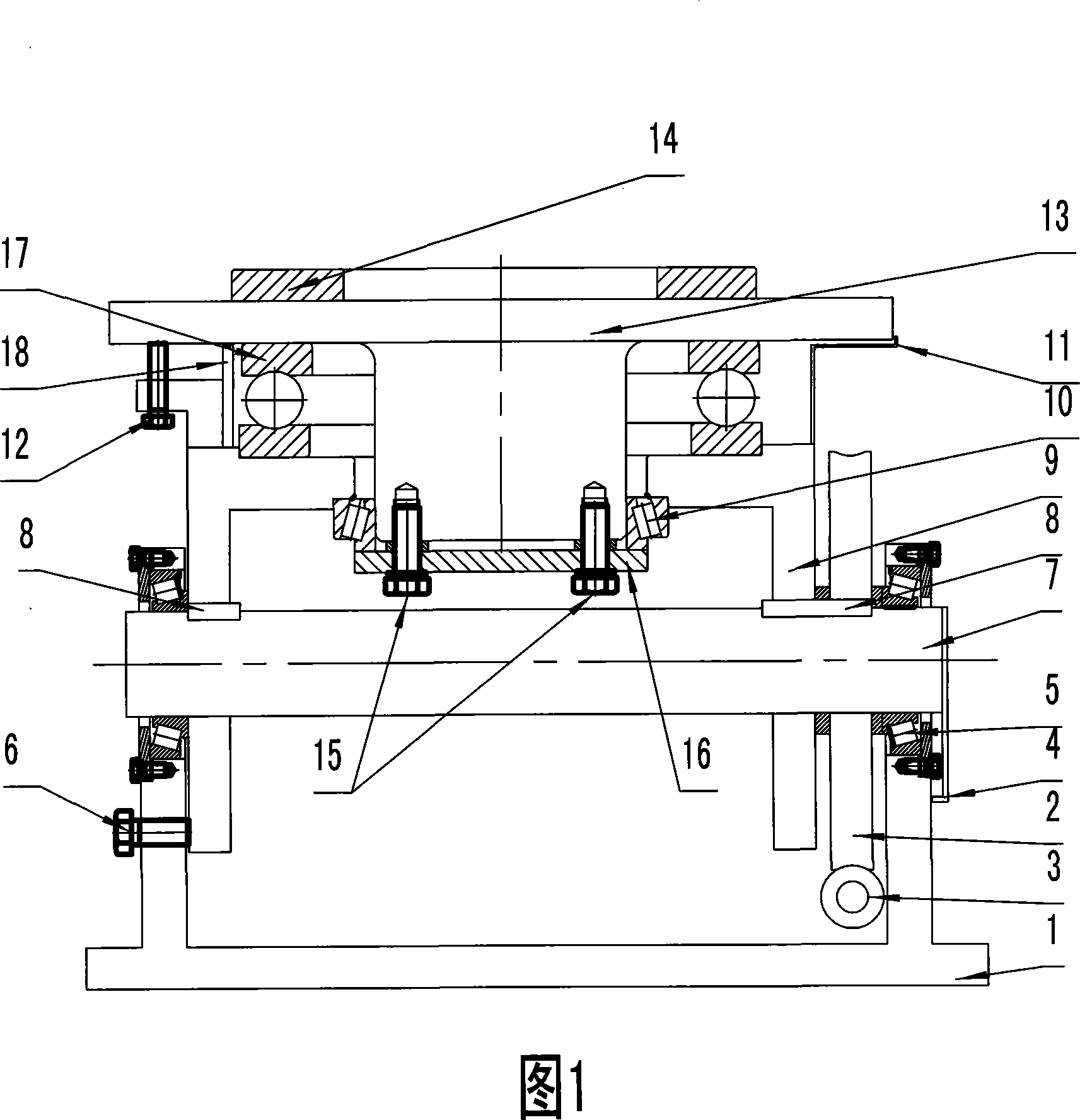

[0053] The practical application of a three-dimensional operating platform for drilling of the present invention will be described in detail below by taking the processing of the cylinder head cooling water hole of a large marine diesel engine as an example.

[0054] The cylinder head of a large marine diesel engine has a cylindrical structure, and 30 cooling water holes should be processed on the ring at the end, and the cooling water holes should be evenly distributed on the end ring. The axis is at an angle of 40 degrees, which requires high machining accuracy when drilling. As shown in FIG. 11 , FIG. 11 is a schematic diagram of the operation of an embodiment of a three-dimensional operation platform for drilling according to the present invention.

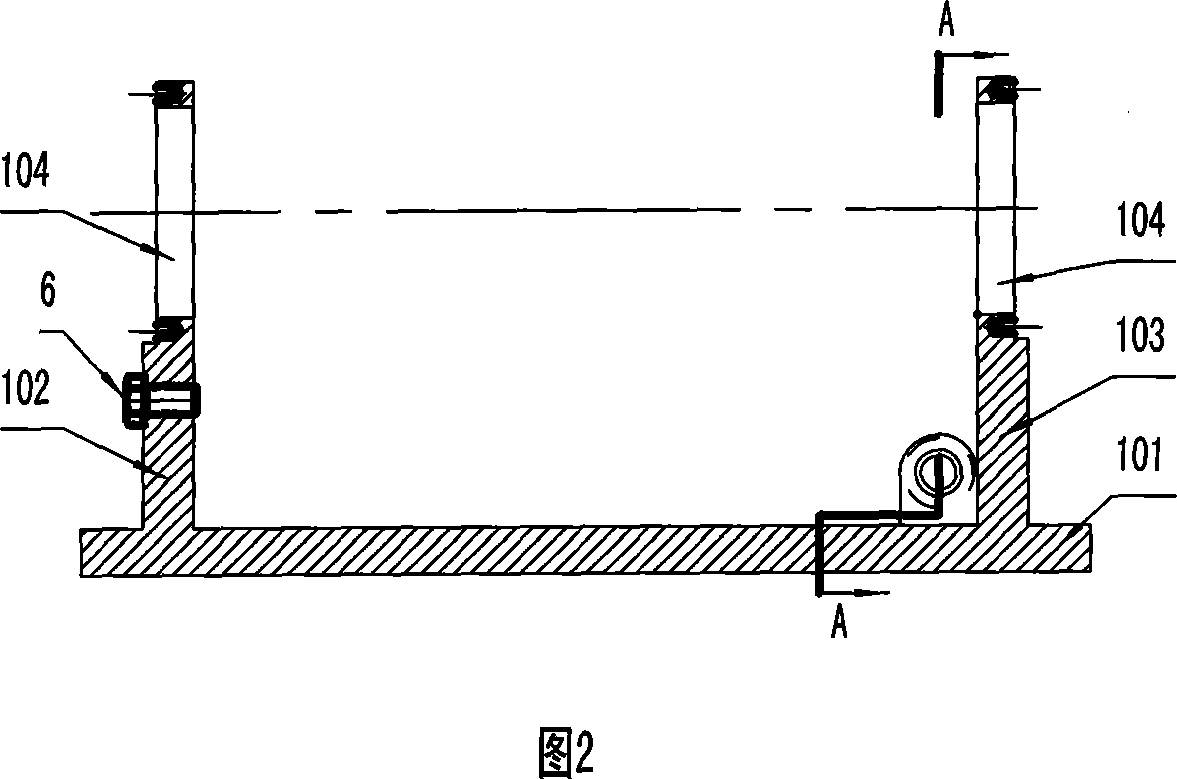

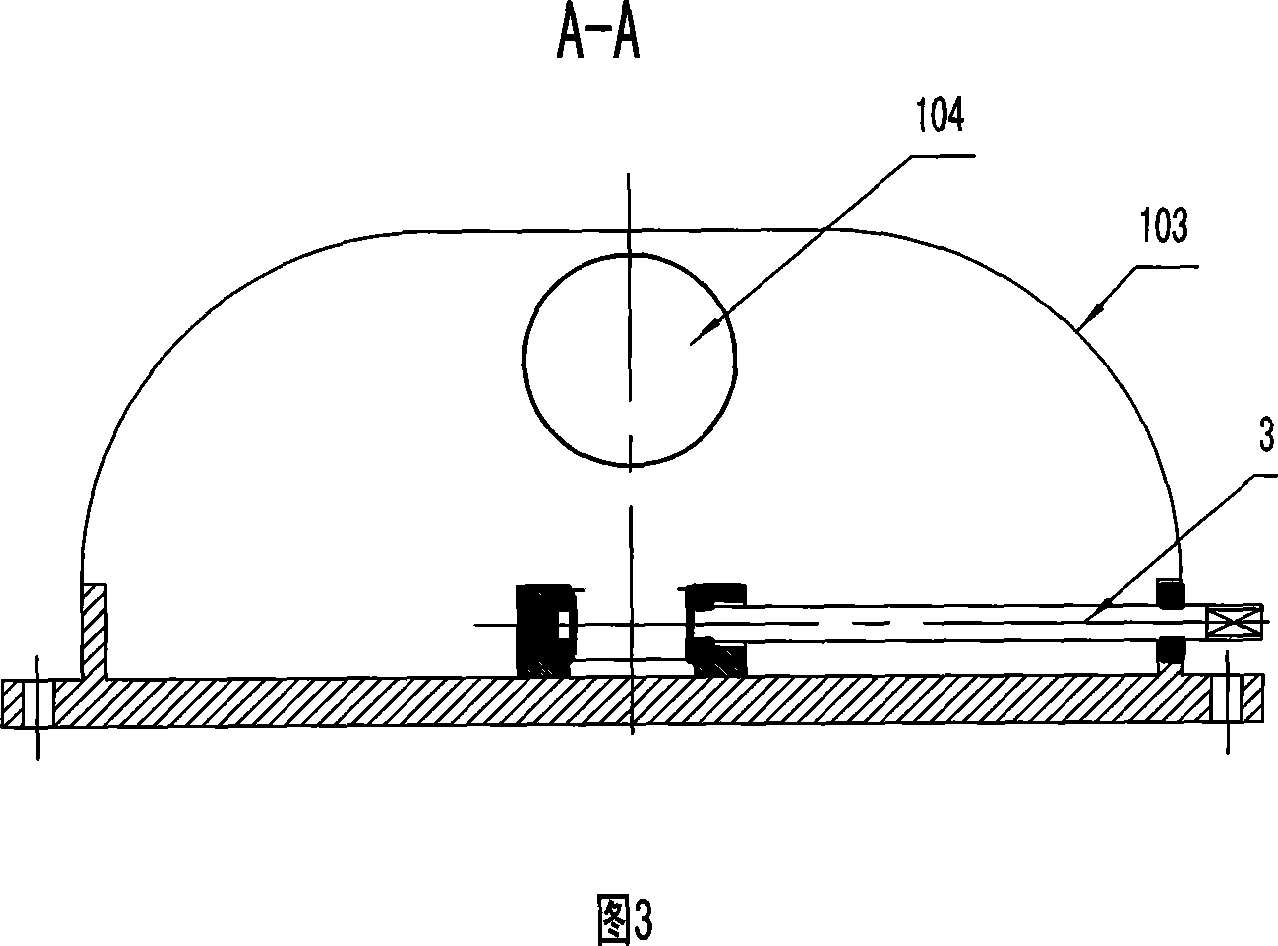

[0055] First, fix the three-dimensional operation platform of the present invention on the workbench of the processing machine tool, fix the base 1 of the three-dimensional operation platform with the anchor bolts of the machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com