Method for extracting genipin and geniposide from gardenia jasminoides

A technology of geniposide and genipin, which is applied in the field of preparation of converting geniposide into genipin, can solve the problems of environmental pollution, cost increase, low purity, etc., and achieves the avoidance of environmental pollution, convenient operation, The effect of simple process

Inactive Publication Date: 2007-09-05

GUILIN NATURAL INGREDIENTS CORP

View PDF0 Cites 18 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The extraction of active ingredients in natural products by this method has certain limitations. The yield of the compounds obtained by the separation is low, the purity is not high, the active ingredients are easily inactivated, and the use of a large amount of organic solvents is likely to cause environmental pollution and increase The investment in safety production is reduced, which leads to the increase of cost

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

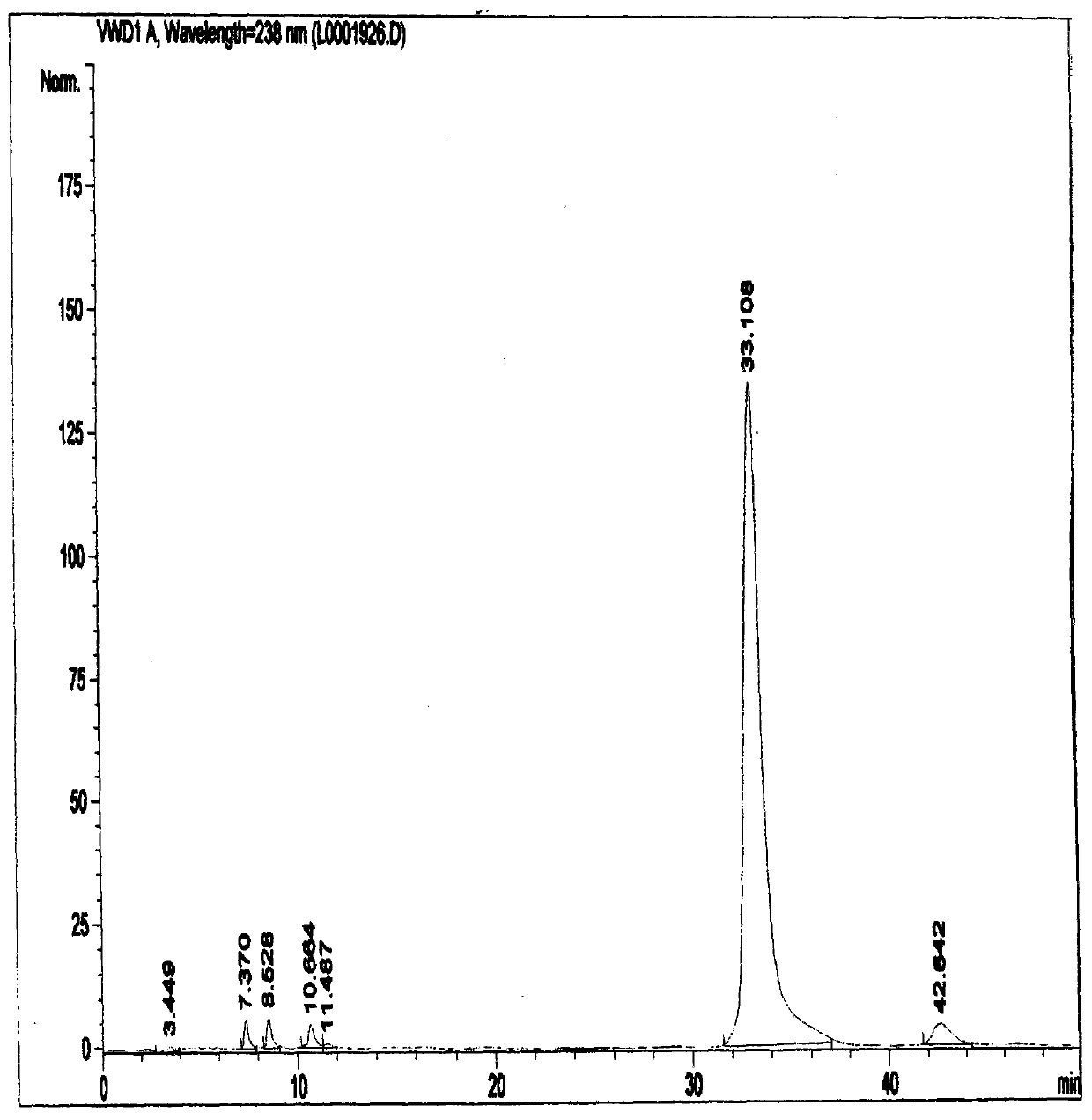

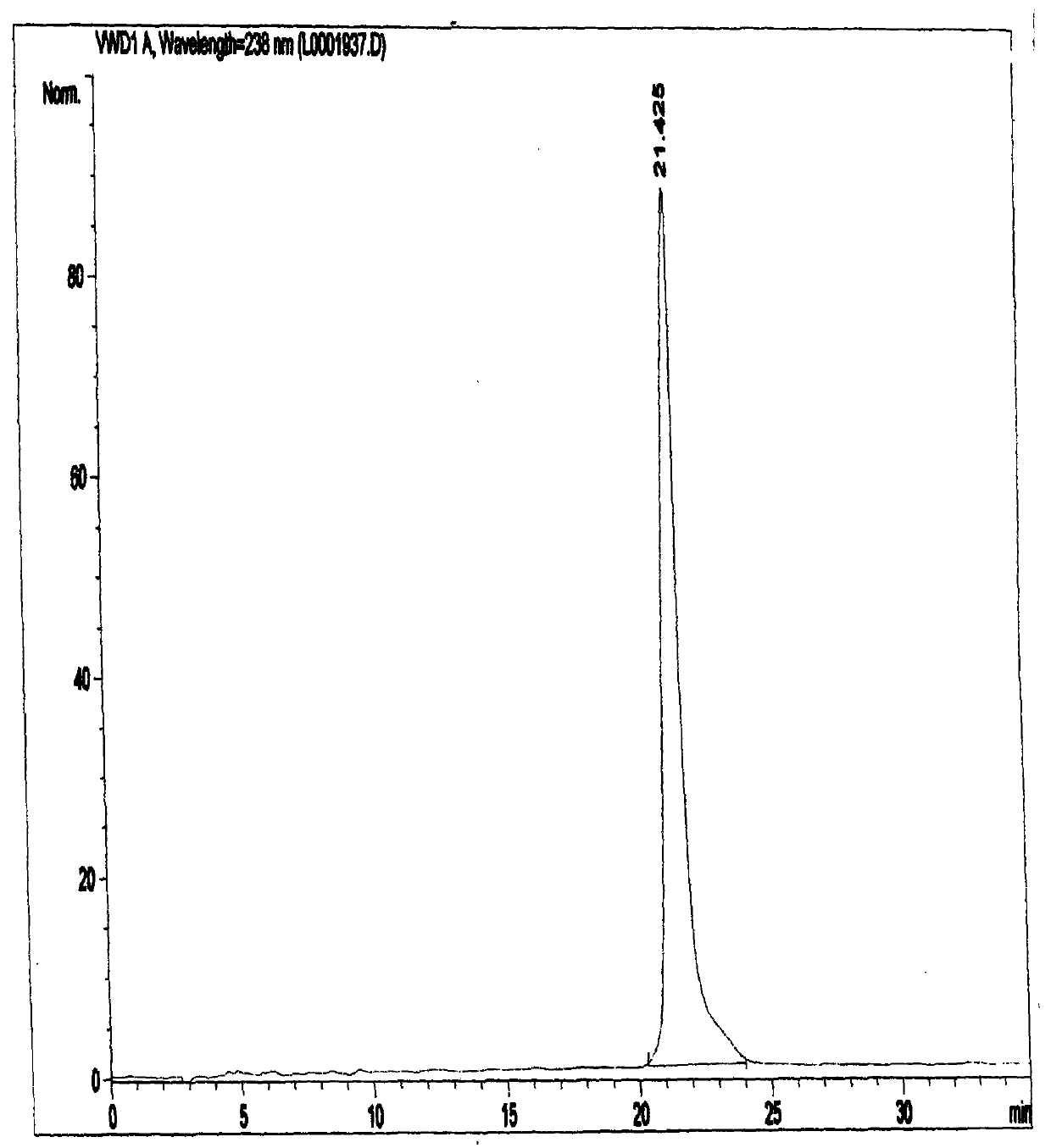

A process for preparing geniposide and genipin from capejasmine fruit includes such steps as extracting, concentrating, chromatography, and freeze-drying to obtain geniposide, or extracting, concentrating, enzymolyzing, chromatography, and freeze- drying to obtain genipin.

Description

technical field The invention relates to a preparation method for extracting geniposide and genipin from gardenia, specifically, to a method for obtaining geniposide from gardenia, and further, converting geniposide into jing The preparation method of Nepin. Background technique Gardenia is the fruit of Gardenia jasminoides Ellis (Gardenia jasminoides Ellis), a plant of Rubiaceae (Rubiaceae), oblong or oval, dark red or yellow-red in color. Gardenia belongs to the first batch of food and medicine dual-use resources promulgated by the Ministry of Health, and is a traditional Chinese medicine. "(Compendium of Materia Medica)" has detailed records: Gardenia has the functions of promoting gallbladder and protecting liver, clearing heat and detoxifying, lowering blood pressure, antibacterial and anti-inflammatory. Traditional Chinese medicine is clinically used to treat jaundice hepatitis, sprains, high blood pressure, diabetes, etc. There are many chemical components in Gard...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C07H17/04C07H1/08C12P17/06

Inventor 孙步祥汤凌志陈振鹏吴柏峰易永基王智慧

Owner GUILIN NATURAL INGREDIENTS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com