Positive exciting magnetic integrated converter of outputting-current corrugated minimum

A technology of output ripple and converter, which is applied in the direction of output power conversion device, adjustment of electric variable, conversion of DC power input to DC power output, etc. It can solve the problems of inability to reduce the volume of magnetic parts and improve the output dynamic performance , Minimize the output current ripple and reduce the effect of current ripple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

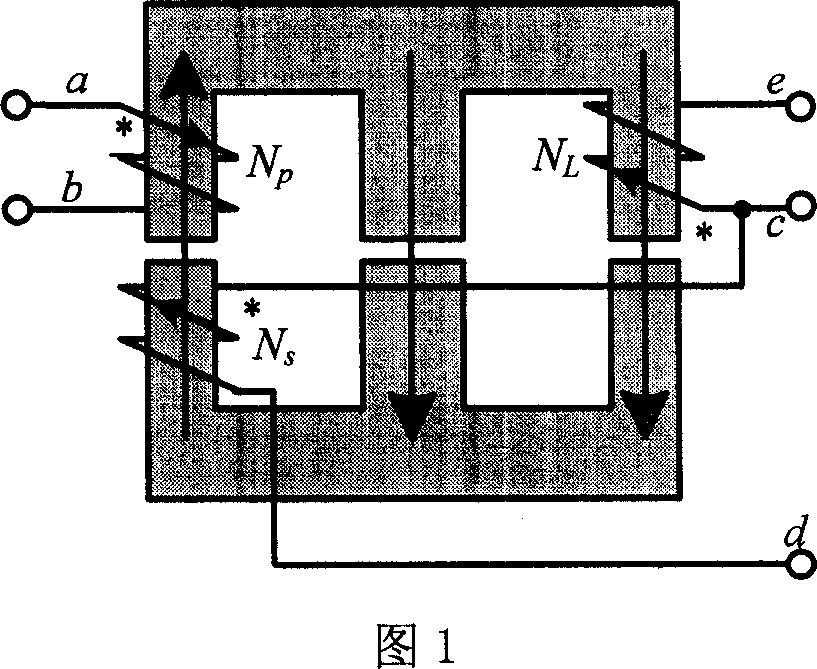

[0018] For an implementation example 1 of an integrated magnetic component using an EE core, refer to FIG. 1 . Primary winding N p , The secondary winding is placed on the side column of the iron core, and the filter inductor winding N L Placed on another iron core side column, point a and point c of the integrated magnetic part are ends with the same name. The iron core is not limited to the EE type.

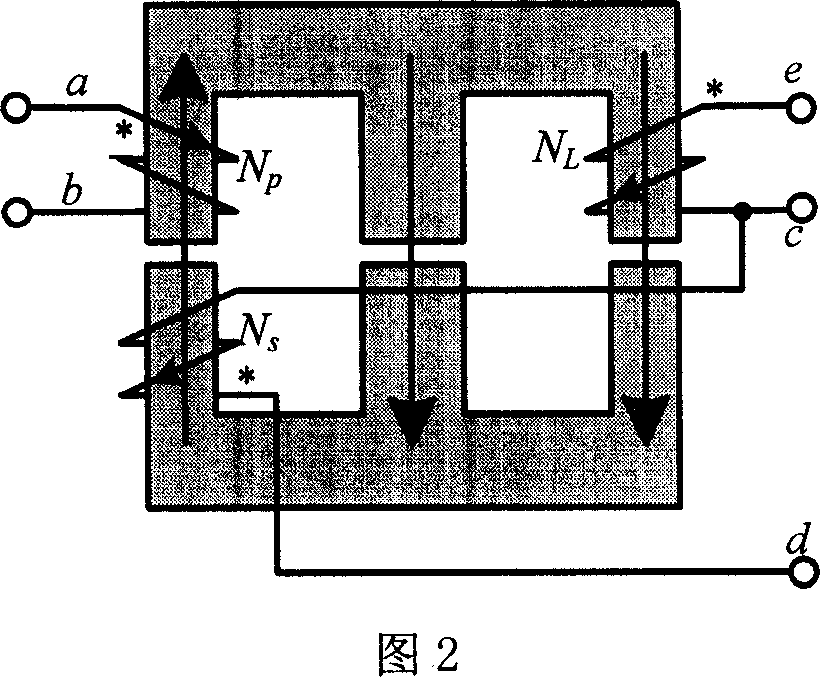

[0019] Refer to the accompanying drawing 2 for the implementation example 2 of the integrated magnetic parts using the EE core. Primary winding N p , The secondary winding is placed on the side column of the iron core, and the filter inductor winding N L Placed on another iron core side column, point a and point c of the integrated magnetic part are different ends. The iron core is not limited to the EE type.

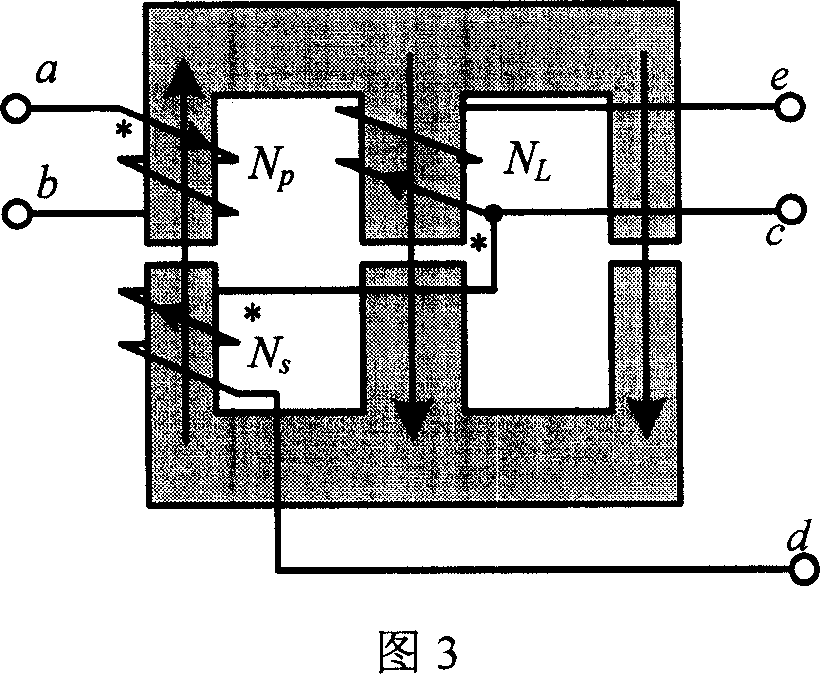

[0020] Refer to the accompanying drawing 3 for the implementation example 3 of the integrated magnetic parts using the EE core. Primary winding N p , The seconda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com