Photocatalyst and its preparing process

A photocatalyst and catalyst technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as poor stability and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

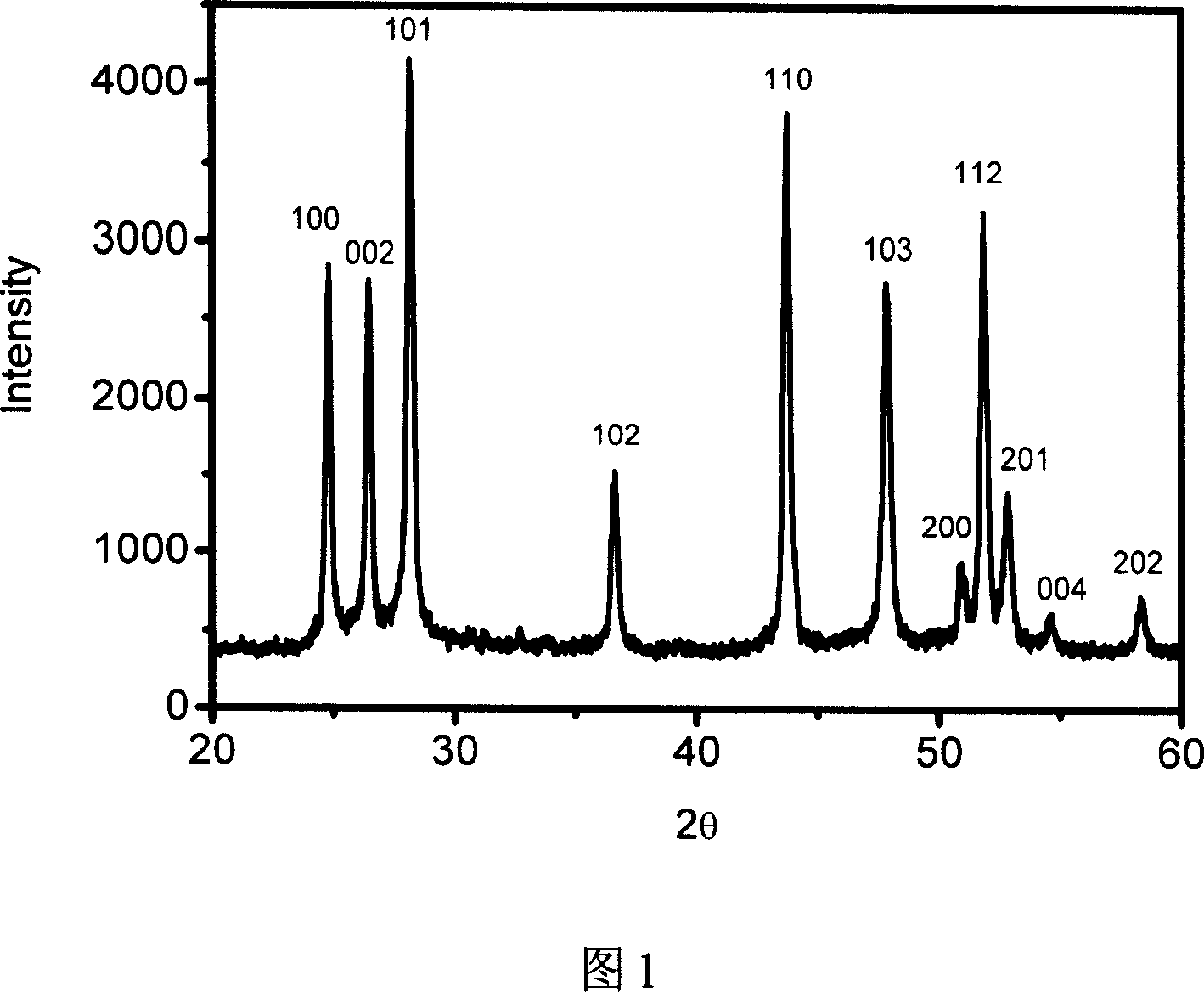

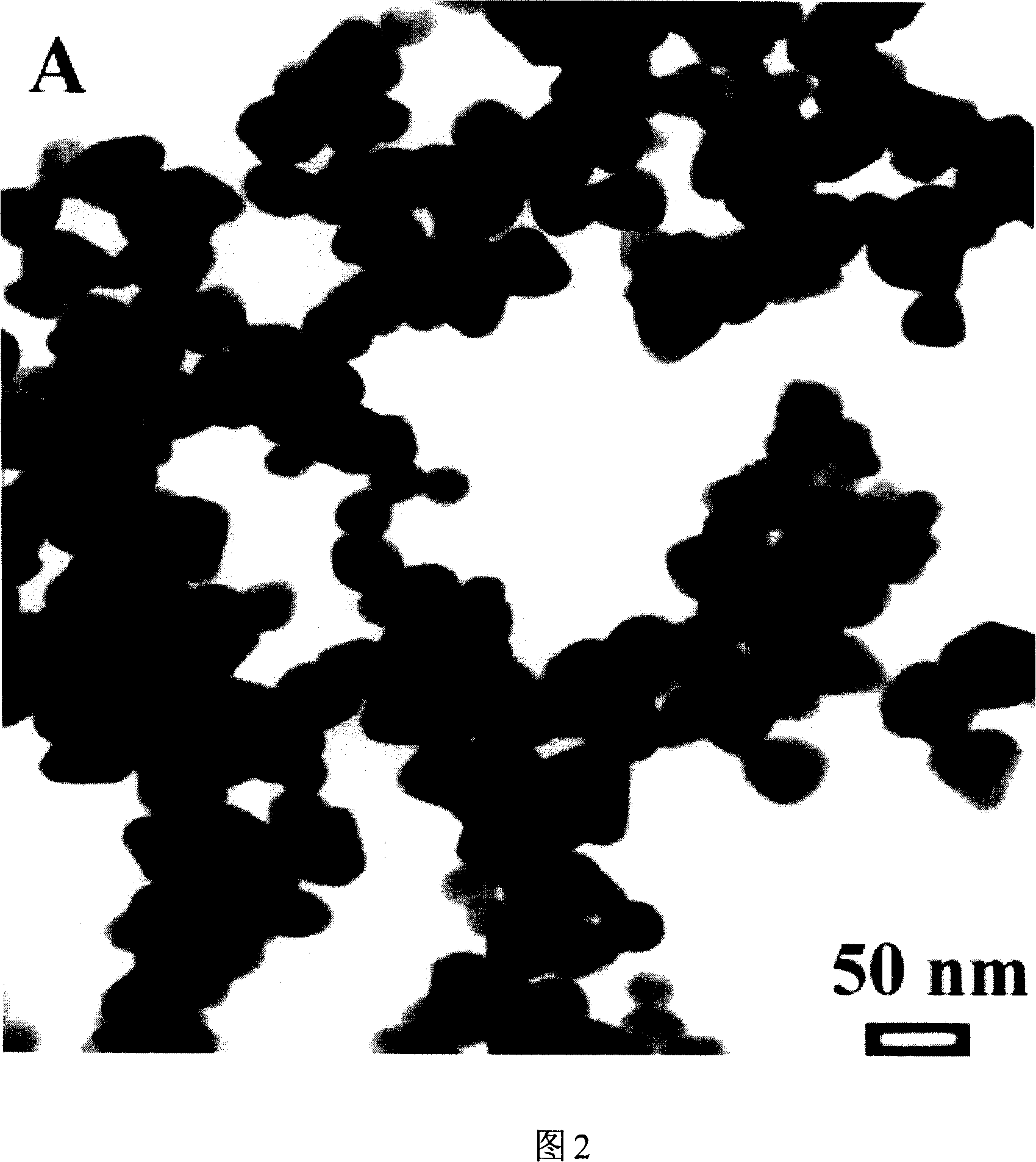

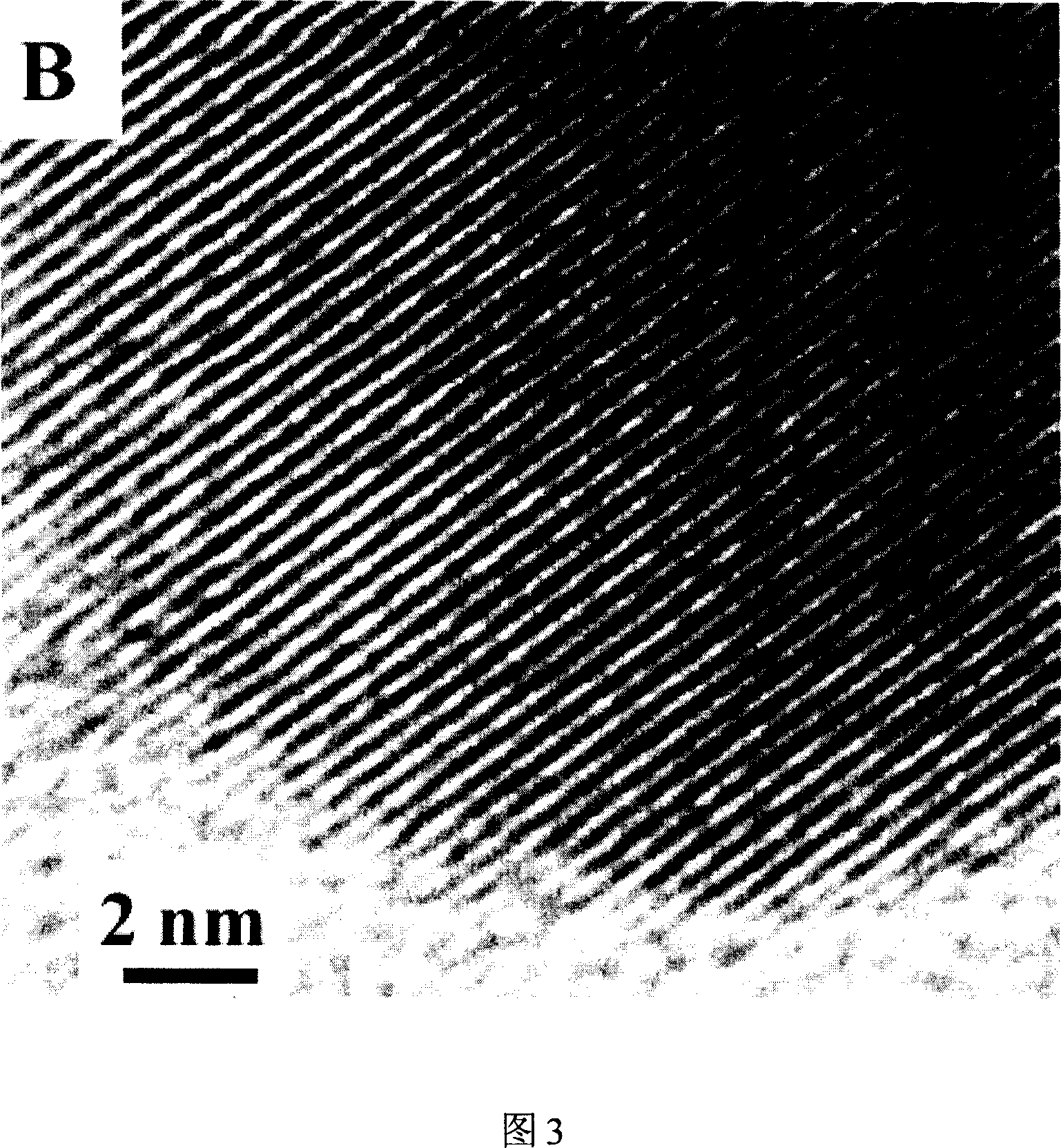

[0028] Embodiment 1: the preparation process of catalyst CdS. Dissolve 20g of cadmium acetate in 500mL of water to form a solution, then add 500mL of 0.14M Na 2 S·9H 2 O solution. After continuing to stir for 24 hours, 830 mL of water was filtered off, and the remaining slurry was transferred to a 200 mL polytetrafluoroethylene-lined autoclave for hydrothermal treatment at 200°C for 24 hours. After filtration, washing and vacuum drying, an orange-yellow precipitate was obtained. The catalyst prepared in this embodiment is a hexagonal phase (see accompanying drawing 1), and the catalyst is a nanoparticle with a high degree of crystallinity, and its diameter is 30-50 nm (see accompanying drawing 2, accompanying drawing 3).

Embodiment 2

[0029] Embodiment 2: Catalyst Cd 0.84 Zn 0.16 The preparation process of S. 20g of cadmium acetate and 3.12g of zinc acetate were dissolved in 500mL of water to form a solution, and then 500mL of 0.14M Na 2 S·9H 2 O solution. After continuing to stir for 24 hours, 830 mL of water was filtered off, and the remaining slurry was transferred to a 200 mL polytetrafluoroethylene-lined autoclave for hydrothermal treatment at 200°C for 24 hours. After filtration, washing and vacuum drying, an orange-yellow precipitate was obtained. The catalyst prepared in this embodiment is mainly based on cubic phase and contains hexagonal phase (see accompanying drawing 4)

Embodiment 3

[0030] Embodiment 3: Catalyst Cd 0.88 Zn 0.12 The preparation process of S. Concrete process is as embodiment 2, but the amount of zinc acetate is changed into 2.26g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com