Visible light photocatalysis air purification material and air purification method

An air purification material and air purification technology, applied in chemical instruments and methods, catalyst activation/preparation, separation methods, etc., can solve problems such as ineffective use of visible light, low photocatalytic oxidation efficiency, and limited photocatalytic technology, etc. To achieve the effect of small secondary pollution, improved adsorption and purification effects, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

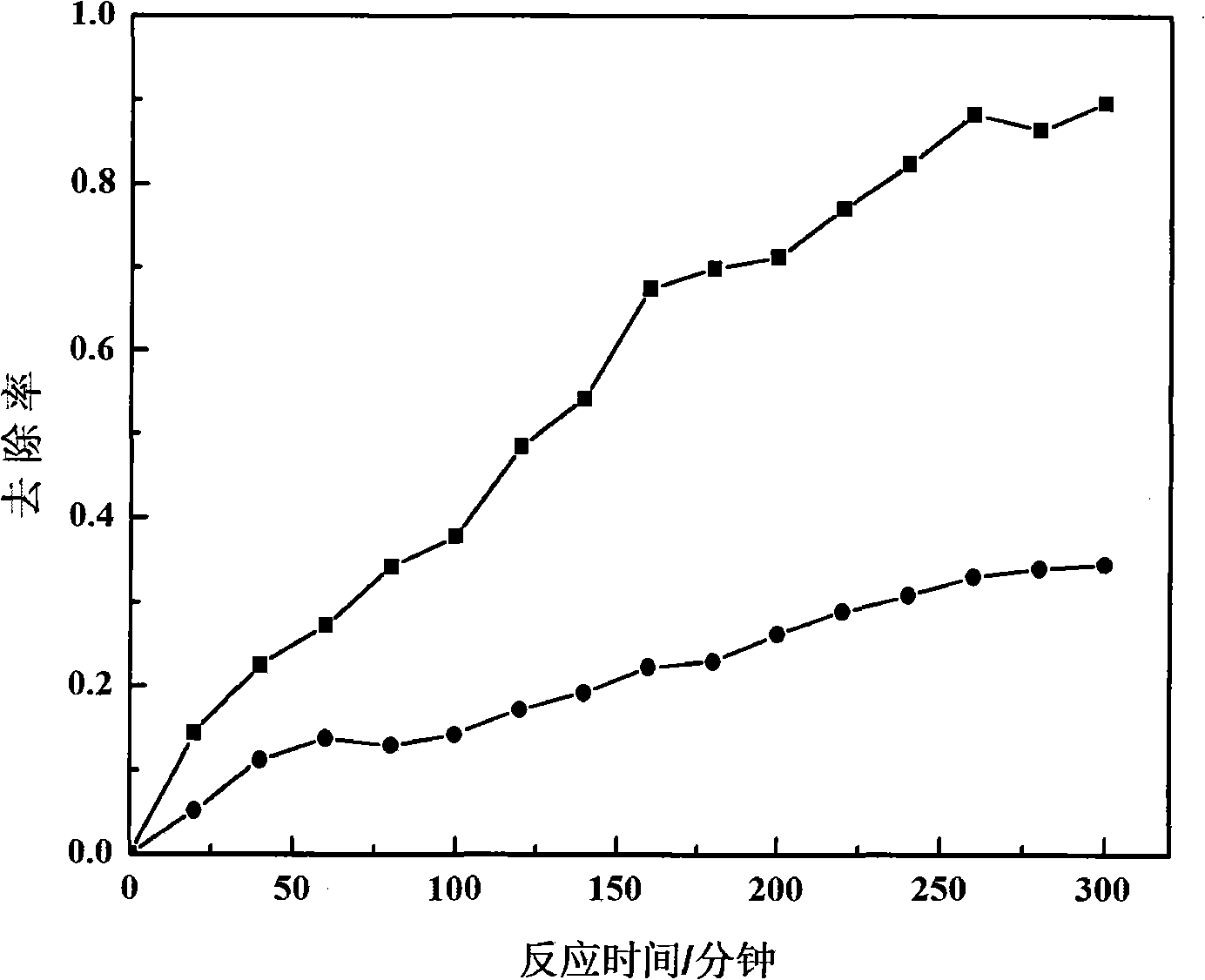

[0015] Preparation of copper oxide / bismuth vanadate composite photocatalyst. Dissolve bismuth nitrate and ammonium vanadate in 4mol / L nitric acid and sodium hydroxide solution at a molar ratio of 1:1, add surfactant P123, stir for half an hour respectively, then mix the above two solutions, and use 2mol / L hydrogen The sodium oxide solution was used to adjust the pH to neutral, and then stirred for half an hour. The precursor solution was poured into a 100mL reactor, and hydrothermally reacted at 200°C for two hours. The product was repeatedly washed with deionized water and absolute ethanol three times, and then dried at 100°C to obtain bismuth vanadate catalyst powder. The prepared bismuth vanadate powder and copper nitrate are weighed according to the weight ratio of copper and bismuth vanadate at 2.5% to 7.0%, mixed with deionized water, evaporated to dryness on a rotary evaporator to powder, and then heated at 300°C The copper oxide / copper vanadate composite nano photocat...

Embodiment 1

[0021] 1. Preparation of copper oxide / bismuth vanadate composite photocatalyst powder

[0022] Dissolve 2.45g bismuth vanadate and 0.58g ammonium vanadate in 10.0mL 4.0mol / L nitric acid solution and sodium hydroxide solution respectively, add 0.25g P 123 to the two solutions respectively, stir for half an hour each, and mix the two solutions The solutions were mixed, and the pH was adjusted to 7.0 using 2.0 mol / L sodium hydroxide solution, and then stirred for half an hour. Put the precursor liquid into a 100mL reaction kettle, and hydrothermally react in an oven at 200°C for two hours. After cooling down to room temperature, wash the product repeatedly with deionized water and absolute ethanol, and dry it at 100°C for four hours to obtain light yellow vanadic acid Bismuth powder. Weigh 0.8098g of bismuth vanadate and 0.1528g of copper nitrate, so that the weight ratio of copper to bismuth vanadate is 5.0%. Place it on a rotary evaporator and evaporate it to dryness to obtai...

Embodiment 2

[0028] 1. Preparation of copper oxide / bismuth vanadate composite photocatalyst powder

[0029] The preparation of bismuth vanadate powder is the same as in Example 1. Then weigh 0.8098g of bismuth vanadate and 0.0764g of copper nitrate, so that copper accounts for 2.5% of the bismuth vanadate. Place it on a rotary evaporator and evaporate it to dryness to obtain a powder, bake it in a muffle furnace at 300°C for four hours, and grind it evenly to obtain a copper-doped 2.5% bismuth vanadate composite photocatalyst powder.

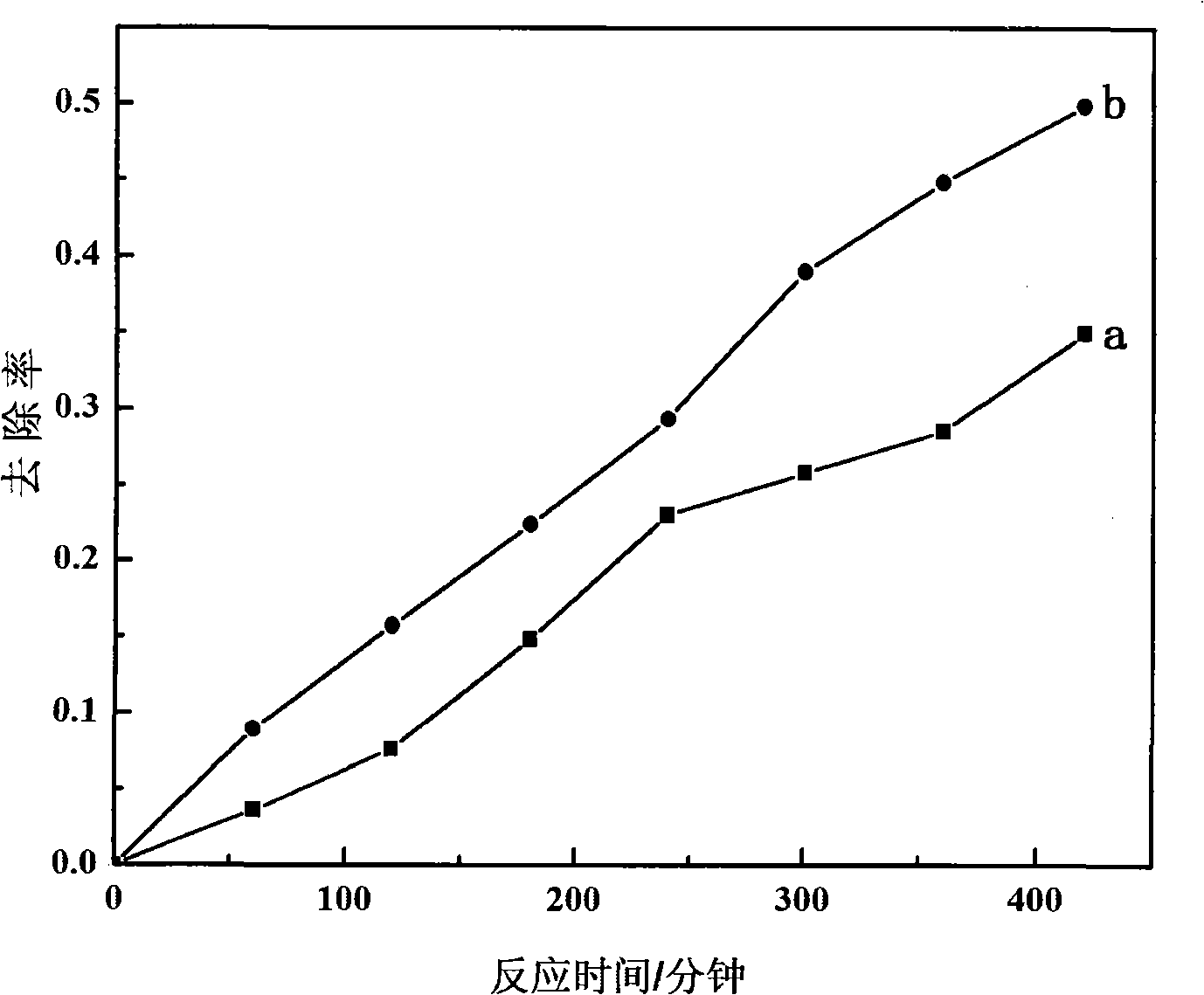

[0030] 2. Preparation of chitosan-modified nylon-supported copper-doped bismuth vanadate photocatalytic material

[0031]The nylon membrane was first hydrolyzed in 1mol / L hydrochloric acid solution at 40°C for four hours, then immersed in 20mL formaldehyde solution, added 0.2mL phosphoric acid, reacted at 60°C for seven hours, and washed with hot water at 40°C-50°C for several times. Then the formaldehyde-activated nylon membrane was immersed in 10mL of 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com