Wood-plastic material and its preparation method

A technology for wood-plastic materials and waste plastics, which is applied in the production of wood-plastic materials, components of wood-plastic materials, and the production process of materials to achieve the effects of increased strength, good environmental and social benefits, and improved strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

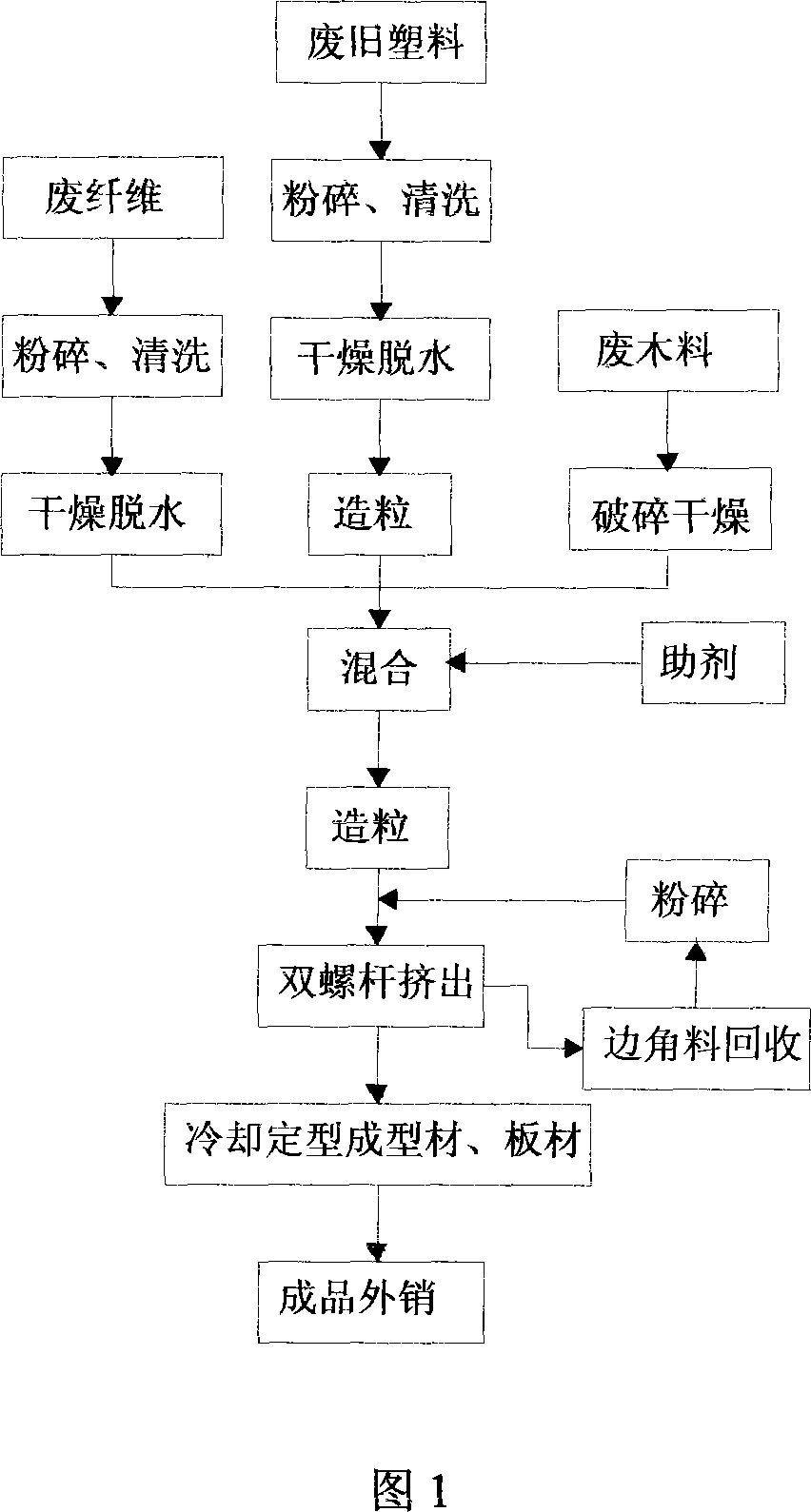

[0019] Please refer to attached picture 1.

[0020] Remove the dust from the plastic (LDPE and PP mass ratio of 5:2) and chemical fiber (acrylic and polyester mass ratio of 1:1) screened in the mineralized garbage, and use a plastic crusher to crush it to 4-6mm. After cleaning Dry until the moisture content is less than 5%. Crush the waste wood blocks in the mineralized garbage to less than 6mm, and use a mill to grind to a particle size of less than 20 mesh.

[0021] The weight ratio of raw materials is (based on the total mass of the product): waste plastics: 25%; wood flour: 55.5%; waste chemical fibers: 15%; silane coupling agent (KH570): 1.5%; Butyl p-cresol: 2.0%; Stearic acid: 0.5%; Paraffin: 1.5%.

[0022] Put the chemical fibers and plastics into the high-speed mixer, and mix briefly at a low speed of 700rpm for 1 minute, then add 0.5% silane coupling agent and mix at a high speed of 1400rpm for 4-6 minutes; after stopping, add dried wood powder and 2-6 di tert-but...

Embodiment 2

[0025] Remove the dust from the plastic (LDPE material) and chemical fiber (acrylic fiber) in the mineralized garbage, use a plastic crusher to crush it to 4-6mm, wash it and dry it until the moisture content is less than 5%. Crush the waste wood blocks in the mineralized garbage to less than 6mm, and use a mill to grind to a particle size of less than 20 mesh.

[0026] The weight ratio of raw materials is (based on the total mass of the product): waste plastics: 45%; wood powder: 50%; waste chemical fibers: 4.0%; silane coupling agent (KH570): 0.2%; Butyl p-cresol: 0.5%; Stearic acid: 0.3%; Paraffin: 0.0%.

[0027]Put the chemical fibers and plastics into the high-speed mixer, and mix briefly at a low speed of 700rpm for 1 minute, then add 0.5% silane coupling agent and mix at a high speed of 1400rpm for 4-6 minutes; after stopping, add dried wood powder and 2-6 di tert-butyl-p-cresol, stearic acid, paraffin, and then mix at high speed for 20-25 minutes. Use a granulator to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com