Three-dimensional multilayer vertical coupling optical interconnected structure and manufacturing method of soft lithography thereof

A vertical coupling, three-dimensional multi-layer technology, applied in the direction of optical waveguide light guide, light guide, optics, etc., can solve the problems of unsatisfactory connection loss, alignment error scattering loss affecting vertical coupling efficiency, low coupling efficiency, etc., to achieve easy soft light Engraving transfer printing, solving vertical coupling and low connection loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

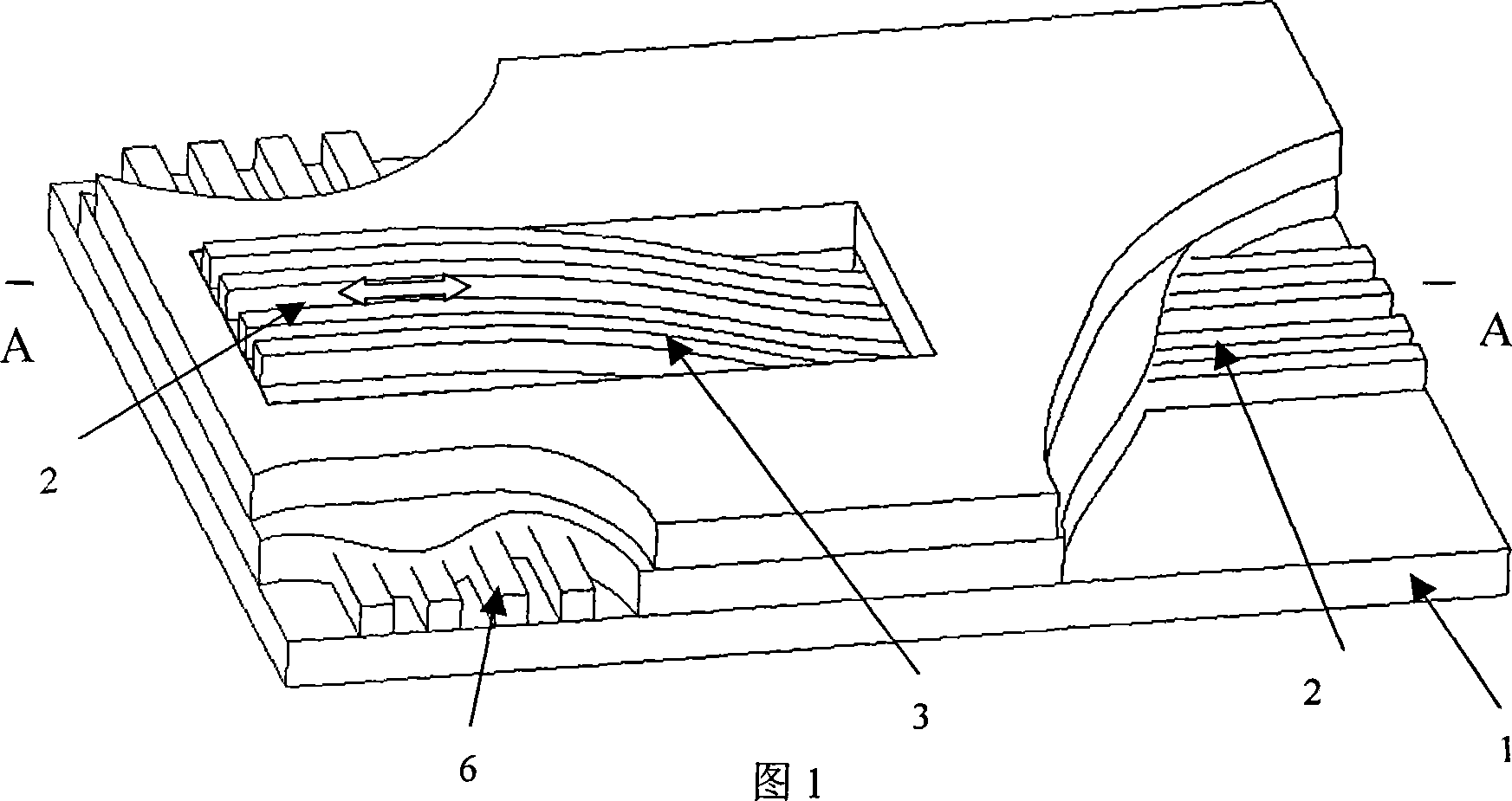

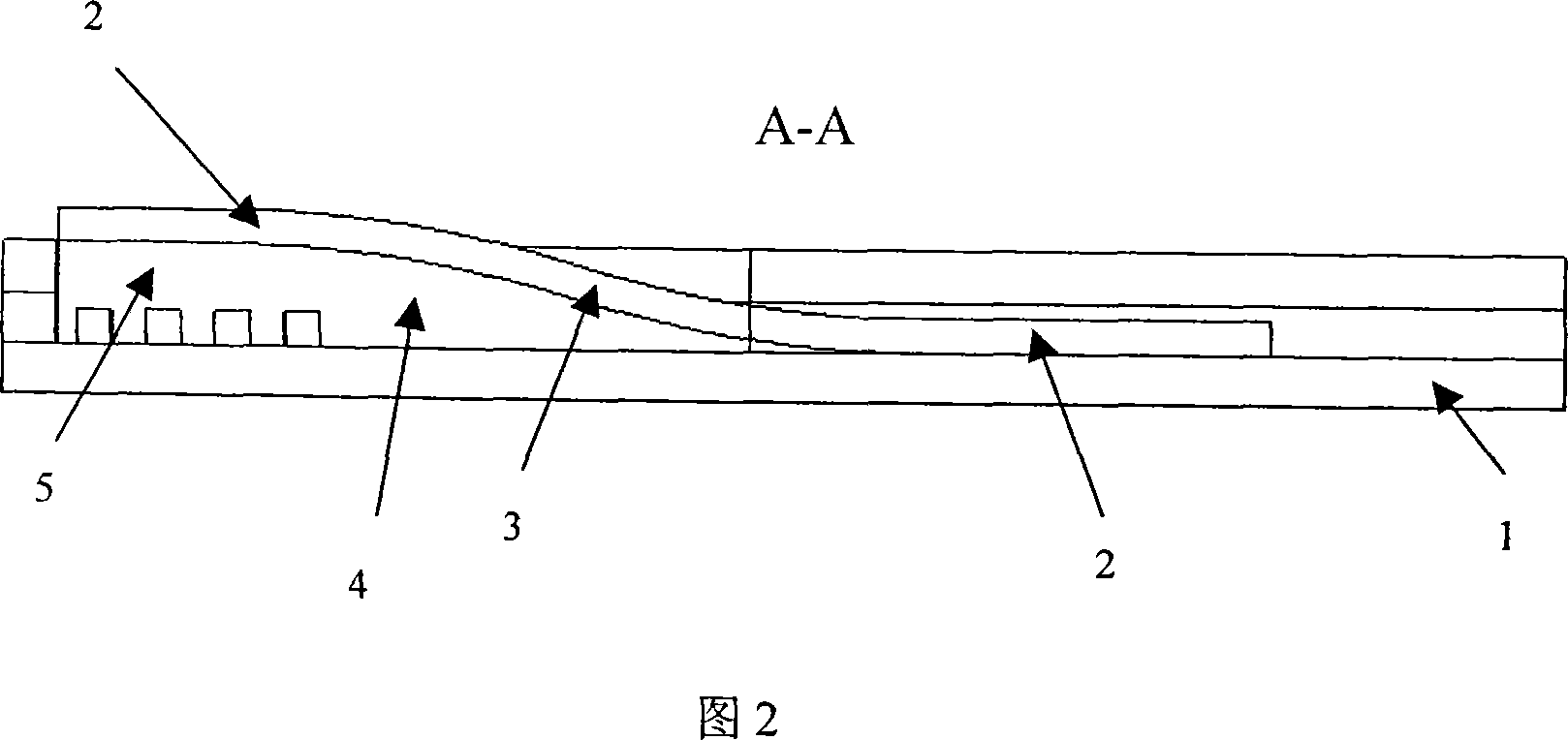

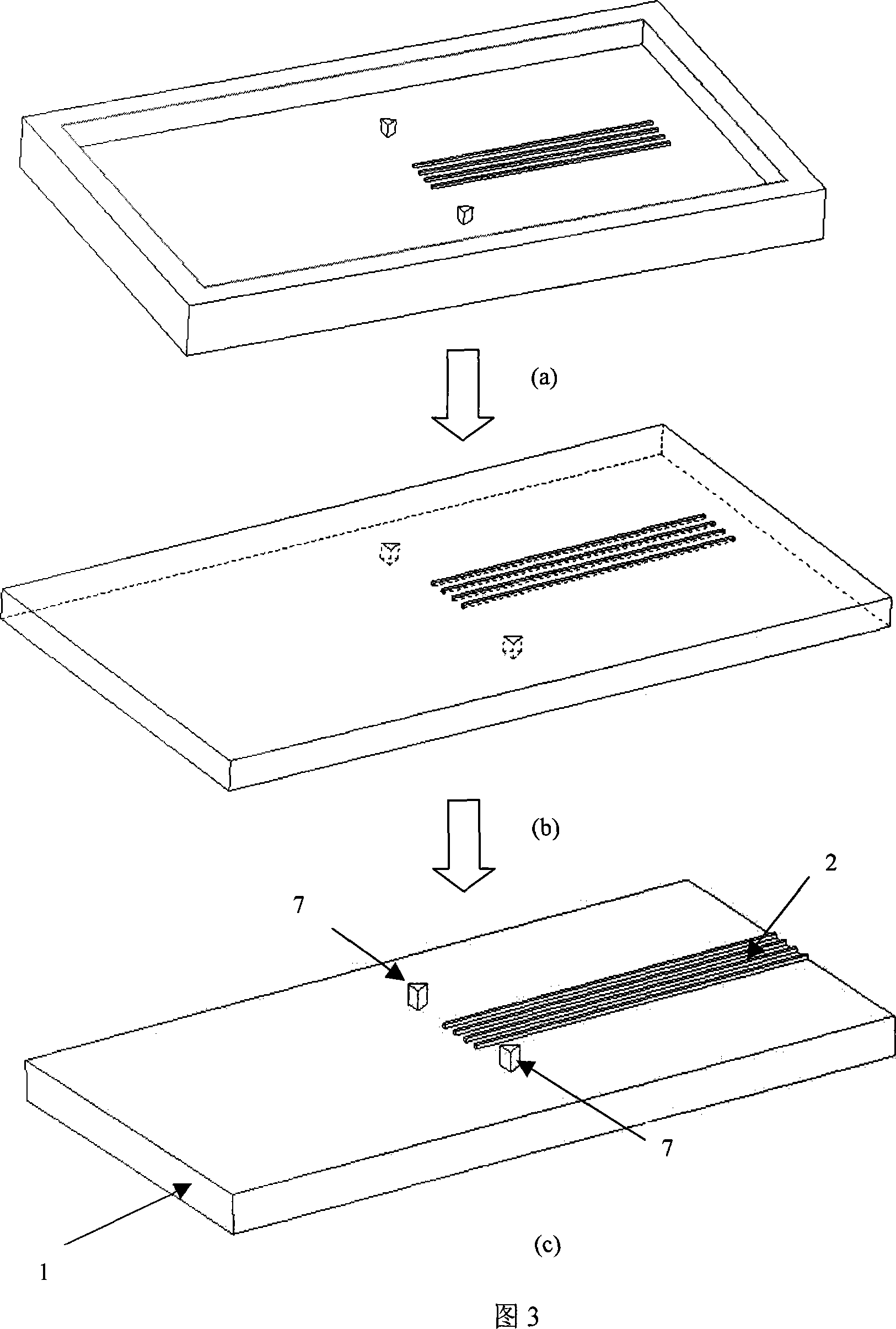

[0019] 1 and 2 are schematic diagrams of a three-dimensional multilayer vertically coupled optical interconnection structure. Including two sets of more than one straight waveguide input and output section 2, S-shaped curved waveguide 3, S-shaped curved slope structure 4, cuboid structure 5, and planar optical transmission waveguide 6; one or more straight waveguide input and output sections 2, S-shaped The curved slope structure 4, the cuboid structure 5 and the planar light transmission waveguide 6 are located on the surface of the substrate 1, the S-shaped curved waveguide 3 is located on the surface of the S-shaped curved slope structure 4, and the input and output section 2 of another or more straight waveguides Located on the surface of the cuboid structure 5, the straight waveguide input and output section 2 on the substrate 1 and the straight waveguide input and output section 2 on the cuboid structure 5 are connected by an S-shaped curved waveguide 3, and the two ends ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com