Nano mildew-proof quick-drying white emulsion and preparation method thereof

A nano, mildew-proof technology, applied in the direction of adhesives, adhesive types, starch adhesives, etc., can solve the problems of poor safety, poor heat resistance, toxicity, etc., and achieve the effect of good bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

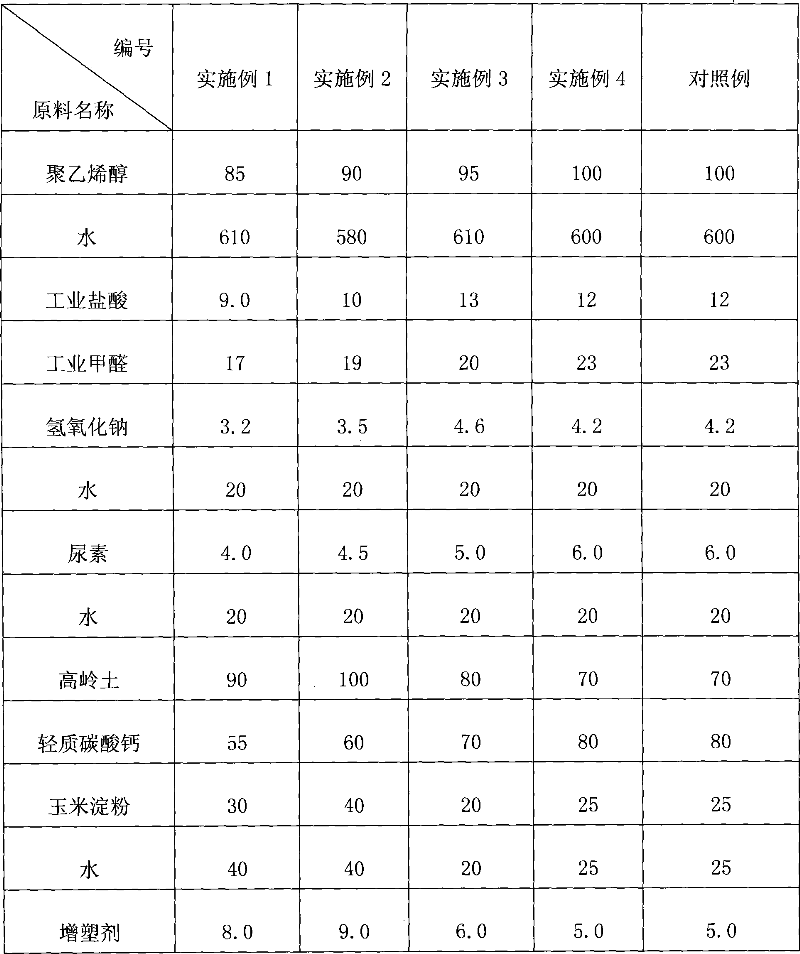

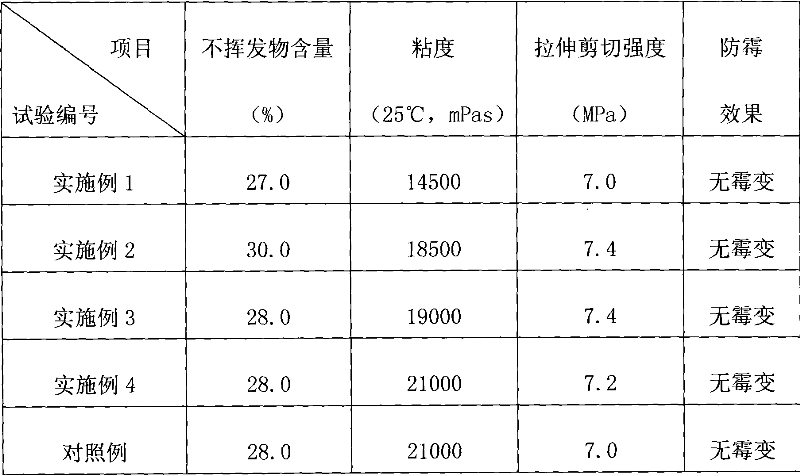

Embodiment 1

[0021] Add 610g of tap water to the reaction kettle, start stirring, add 85g of polyvinyl alcohol, heat up to 95°C to dissolve for 1 hour, add 9.0g of hydrochloric acid and 17g of formaldehyde, and control the reaction temperature at 90-95°C. When separation (water separation) occurs, add sodium hydroxide solution (sodium hydroxide 3.2g, water 20g), adjust the pH value of the material to 6.0-7.0, cool down to 80°C, add urea aqueous solution (urea 4.0g, water 20g), Maintain the temperature of 80°C for 30 minutes; adjust the temperature to 80-85°C, add 90g of kaolin and 55g of light calcium carbonate, stir and disperse for 30 minutes, then add cornstarch milk (30g of cornstarch, 40g of water), disperse and gelatinize for 30 minutes Minutes, lower the temperature to 45°C, add 8.0g of plasticizer, 2.0g of inorganic nano antifungal agent, add 6.8g of water, continue to stir for 1-2 hours, and finally filter the material through a 60-mesh filter to obtain the product of the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com