Apparatus for cold rolling copper ball

A technology of copper balls and rolls, applied in bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of long time for adjustment and maintenance, high equipment adjustment requirements, boring guide plate rolling mill, etc. Shorten welding, stable and reliable effect of forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

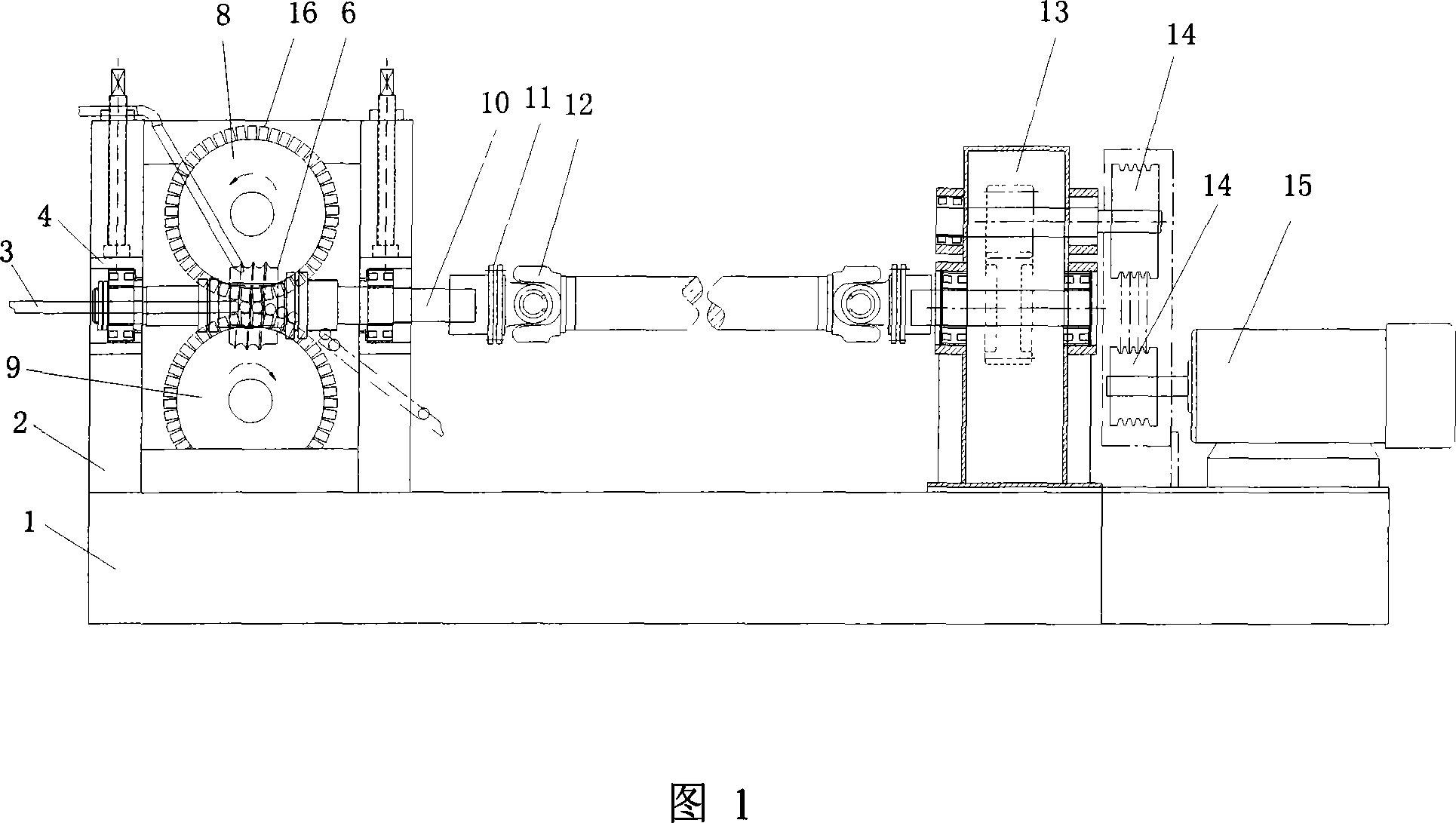

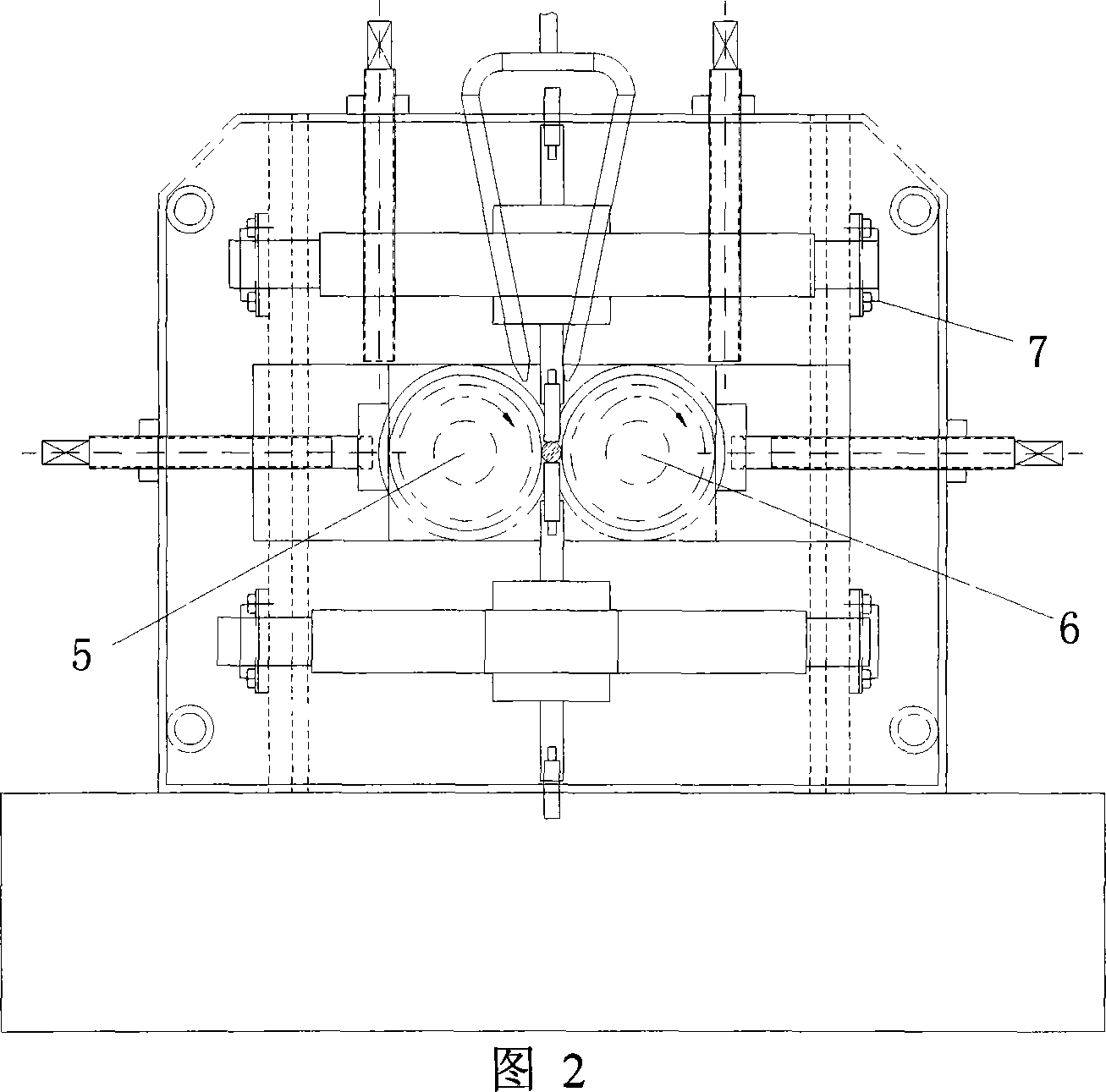

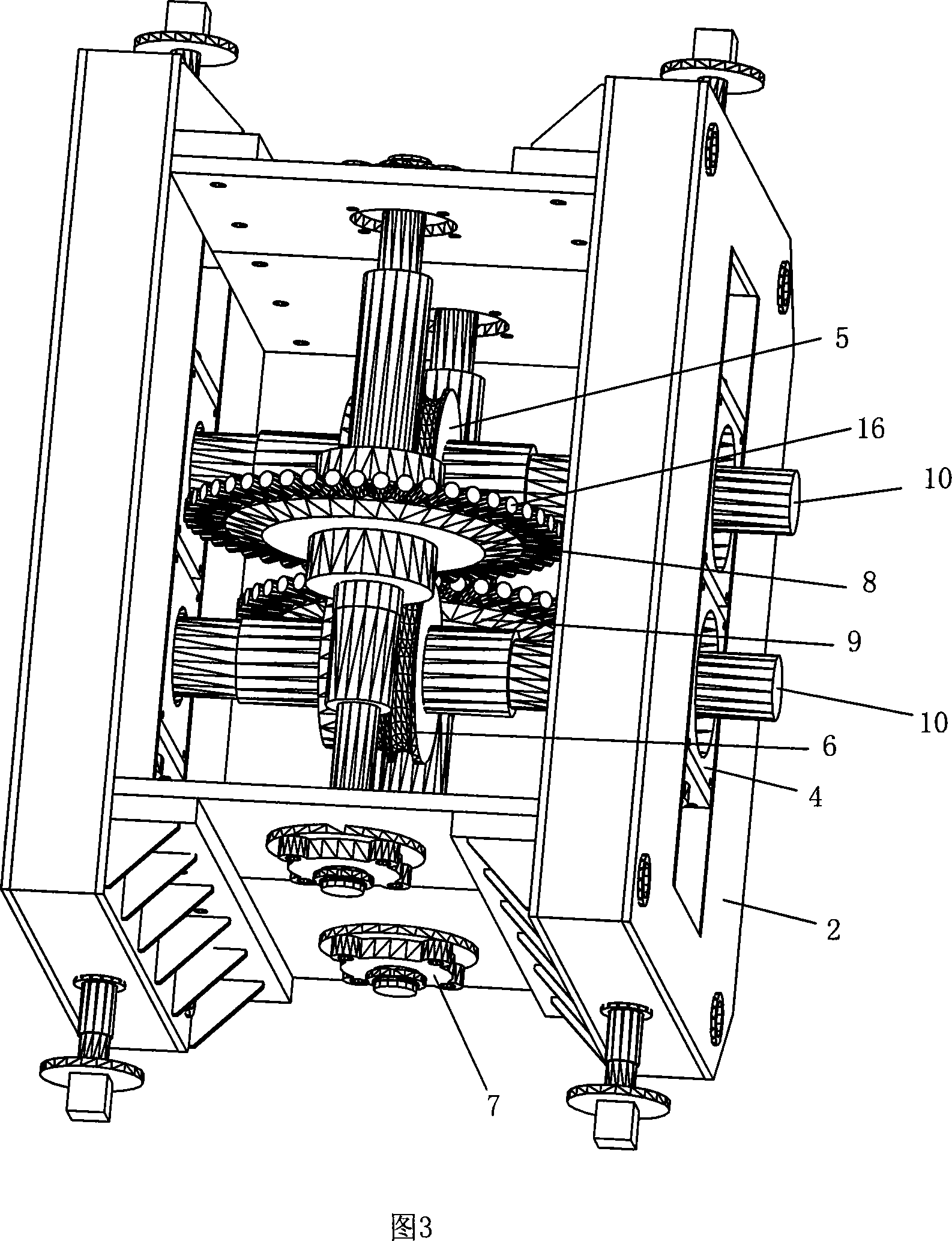

[0028] The copper ball cold rolling mill shown in Figure 1 and Figure 2 includes a fixed frame 1, a copper ball cold rolling device, a power mechanism, and a transmission shaft. The copper ball cold rolling device on the left is connected with the power mechanism on the right through the transmission shaft in the middle, and is installed on the fixed frame 1. The power mechanism on the right side comprises motor 15, belt pulley 14, speed reducer 13. The motor 15 drives the belt pulley 14 to rotate, and through the speed reducer 13, drives the transmission shaft to rotate. The copper ball cold rolling device includes a frame 2, an upper guide plate 8, a lower guide plate 9, a left roll 5, and a right roll 6. The upper guide disc 8 and the lower guide disc 9 are movable circular guide discs, the upper circular guide disc 8 and the lower circular guide disc 9 are rotatably connected on the frame 2, and the upper circular guide disc 8 and the lower circular guide disc 9 are on th...

Embodiment 2

[0035] Fig. 6 has shown another structure of the present invention, as can be seen from Fig. 6, this copper ball cold-rolling device is the same as embodiment 1 except the following features: the lower round guide plate 9 is replaced by the flat guide plate 17 that is arranged horizontally, described The upper circular guide plate 8 is rotatably connected to the frame 2, the flat guide plate 17 is fixed on the frame 2, and the left and right roll screws 5, 6 are embedded in the teeth of the upper circular guide plate 8. 16 and between the upper circular guide plate 8 and the lower flat guide plate 17.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com