Method for producing asphalt for high grade road

A technology of road asphalt and production method, which is applied in the processing of tar asphalt/petroleum asphalt/natural asphalt, processing tar asphalt/petroleum asphalt/natural asphalt by selective extraction, and petroleum industry, and can solve the problem of reducing the wax content of asphalt blending components Content, poor applicability and other problems, to achieve the effect of optimizing operation, solving the problem of operating rate and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

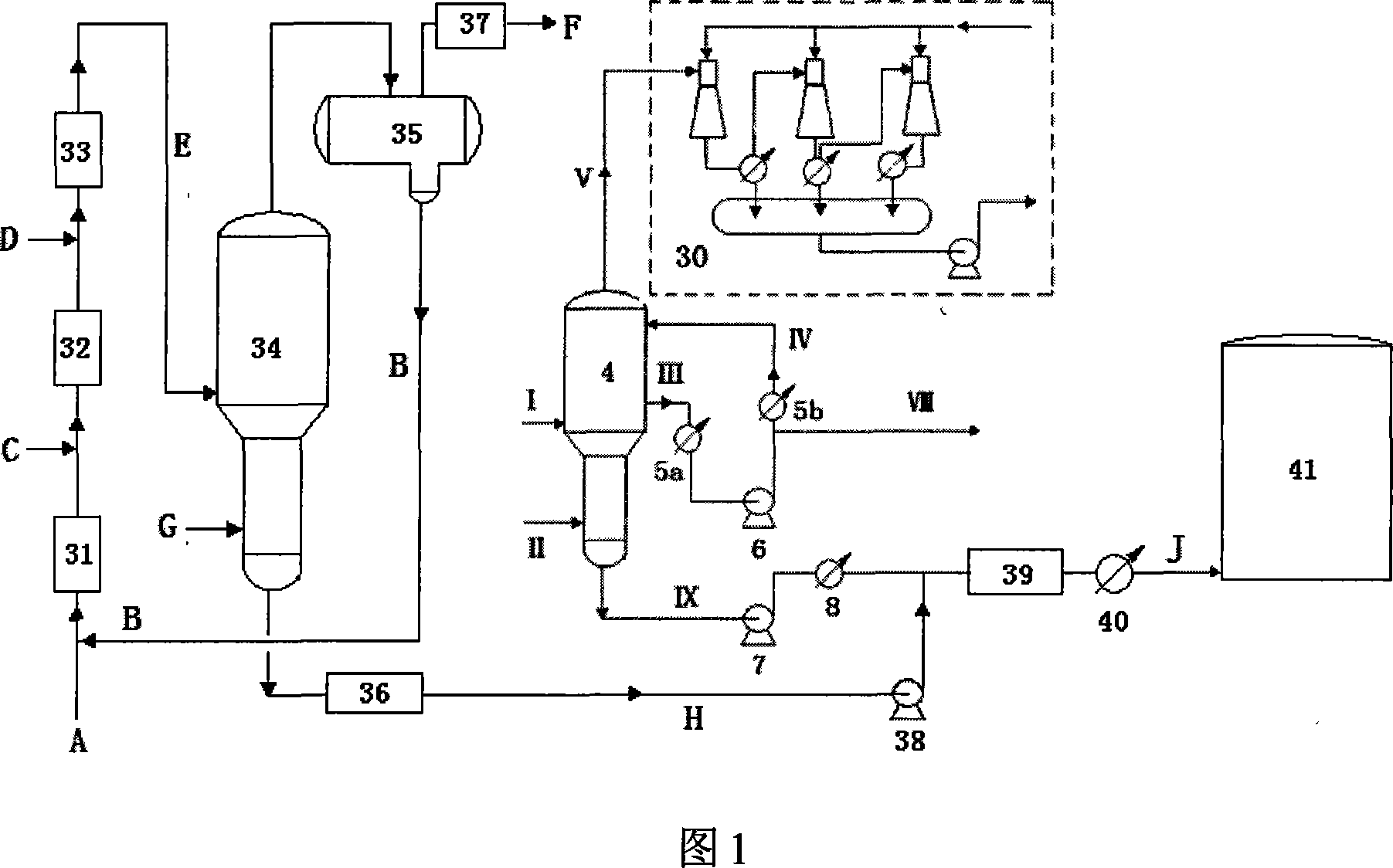

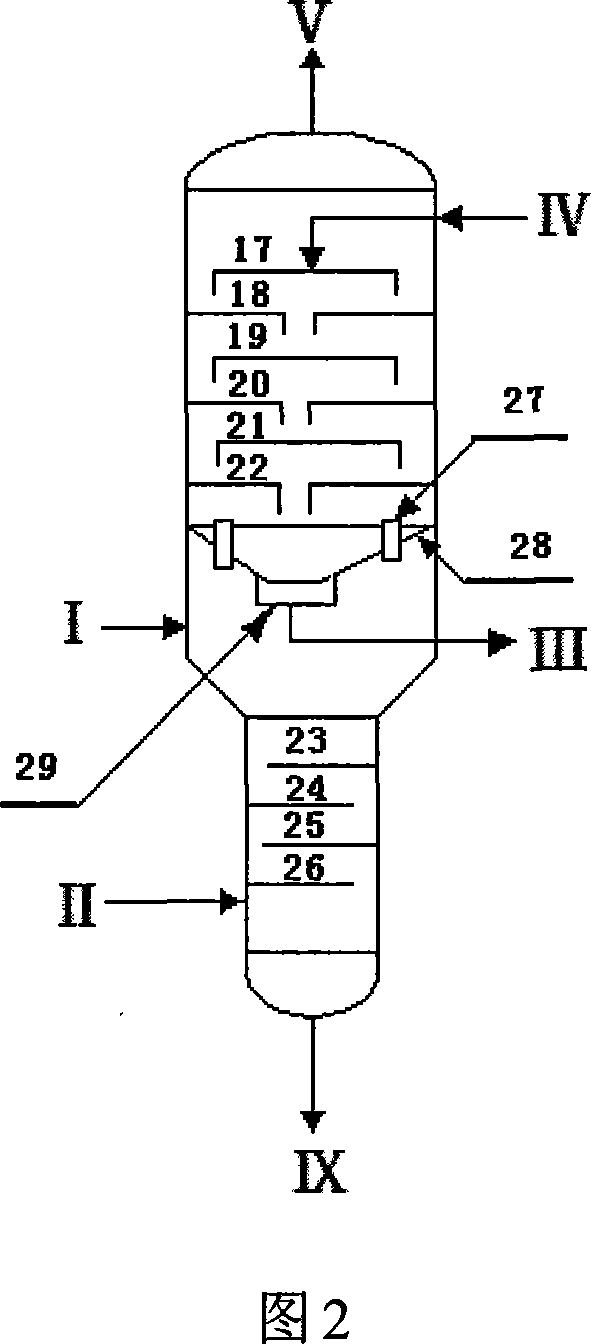

[0034] The mixed vacuum residue A with the blending ratio of Zhongyuan crude oil (paraffin base) and Oman crude oil (intermediate base) at a blending ratio of 30:70 (weight) enters the first-stage mixer 31 together with the circulating gum B, where it is fully mixed, and then beaten The diluent butane C, which accounts for 16% of the total solvent weight, enters the secondary mixer 32 for thorough mixing, and then the main solvent D, which accounts for 70% of the total solvent weight, is injected, and the temperature is controlled to 115°C. The lower part of 34 is driven into the sub-solvent butane G, which accounts for 14% of the total solvent weight, and the continuously sinking asphalt phase is further extracted on the tray to reduce the wax content of the asphalt phase. The butane solvent is used throughout the extraction process. The volume ratio of (dilution solvent + main solvent + auxiliary solvent) to vacuum residue is 8:1. The bitumen solution extracted from the bottom o...

Embodiment 3

[0043] The mixed vacuum residue A with the mixing ratio of Zhongyuan crude oil (paraffin base) and Oman crude oil (intermediate base) at a blending ratio of 40:60 (weight) enters the first-stage mixer 31 together with the circulating gum B, where it is fully mixed, and then beaten Into the diluent solvent butane C accounting for 8% of the total solvent weight enters the secondary mixer 32 for thorough mixing, and then enters the main solvent D accounting for 80% of the total solvent weight, and the temperature is controlled to 112°C. From the asphaltene extractor 34 The as-solvent butane G, which accounts for 12% by weight of the total solvent, is injected into the lower part of the solvent, and the continuously sinking asphalt phase is further extracted on the tray to reduce the wax content of the asphalt phase. The butane solvent ( The volume ratio of dilution solvent + main solvent + auxiliary solvent) to vacuum residue is 6:1. The bitumen solution extracted from the bottom of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com