Cable running safety monitoring method

A safety monitoring and cable technology, applied in electrical signal transmission systems, thermometer parts, measuring devices, etc., can solve the problems of poor anti-interference ability, the transmission distance should not be too long, the development is slow, etc., to ensure the effect of safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

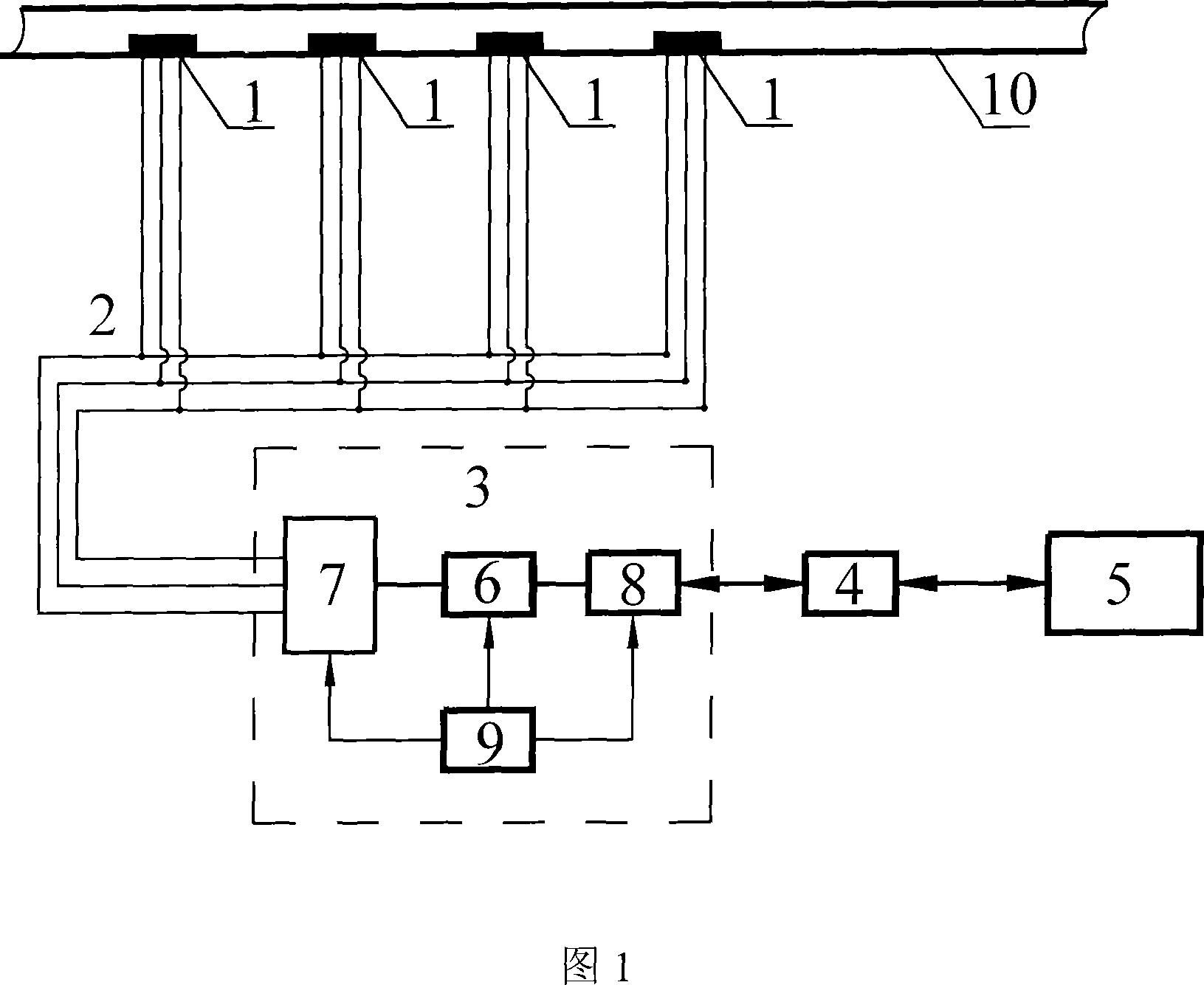

[0102] The cable safety monitoring and operation evaluation method and its device of the present invention are composed of a temperature measuring element 1, a data transmission line 2, a data acquisition circuit assembly 3, a data conversion circuit 4, a computer 5, a cable 10 and its control software.

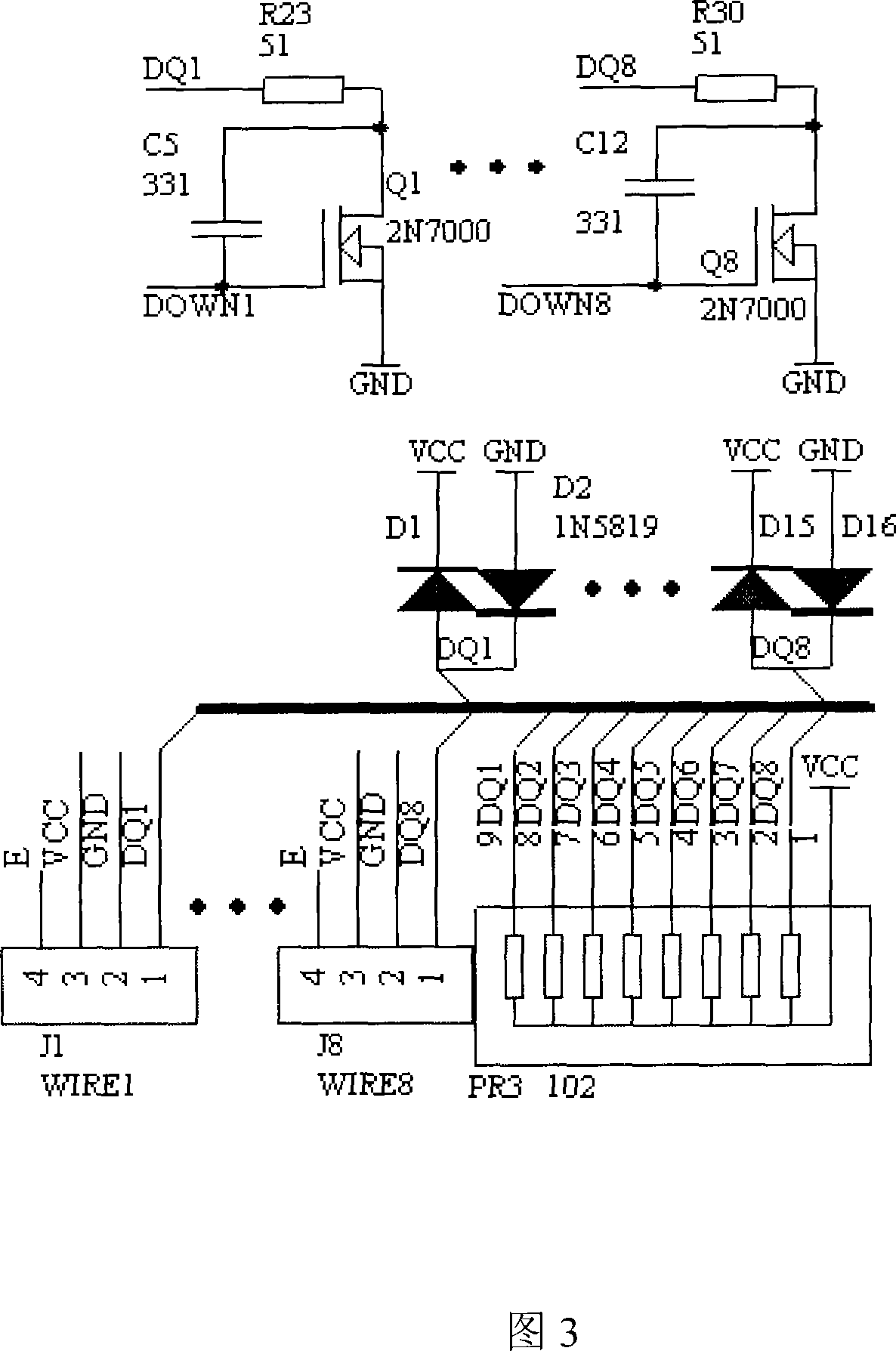

[0103] In this embodiment, the temperature measuring element 1 refers to the 18B20 semiconductor temperature probe, which is encapsulated in the metal shell by heat-conducting glue, and the metal shell is fixed on the outer wall of the cable by plastic cable ties. The three legs of the temperature probe are respectively connected to the data transmission line 2 The ground wire, the data wire and the power wire are connected, and the data transmission line 2 is composed of three-core wires, and the outer walls of the wires are respectively wrapped with aluminum foil, copper mesh, inner sheath layer, steel armor and outer sheath layer.

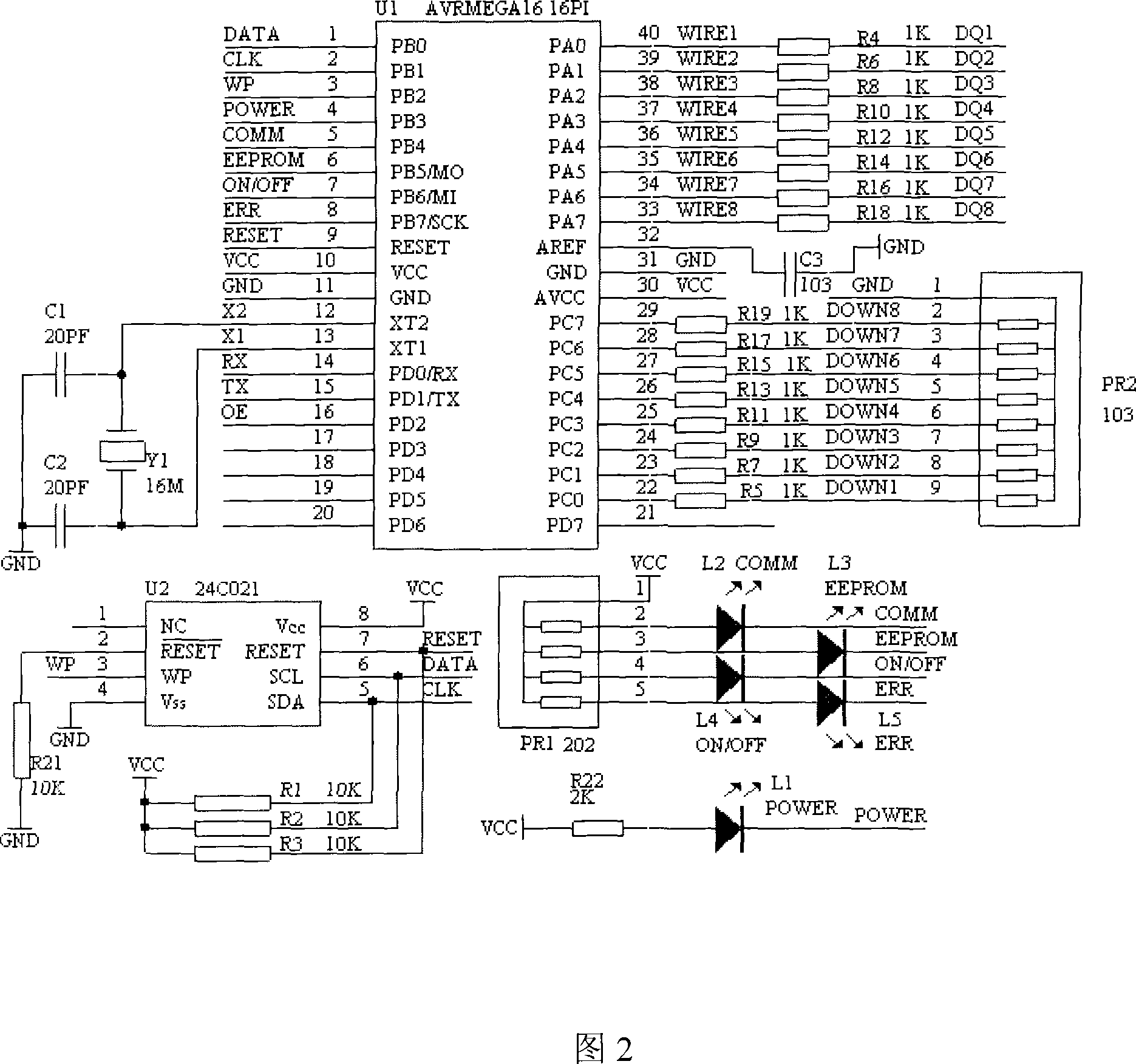

[0104] The data acquisition circuit assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com