Deep-processing method and product of highland barley wild oat

A technology of deep processing and highland barley, applied in food preparation, application, food science, etc., can solve problems such as uneven distribution of nutrients in highland barley grains, poor sanitation conditions in the production process, backward processing technology, etc., so as to improve the technological content and The effect of added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

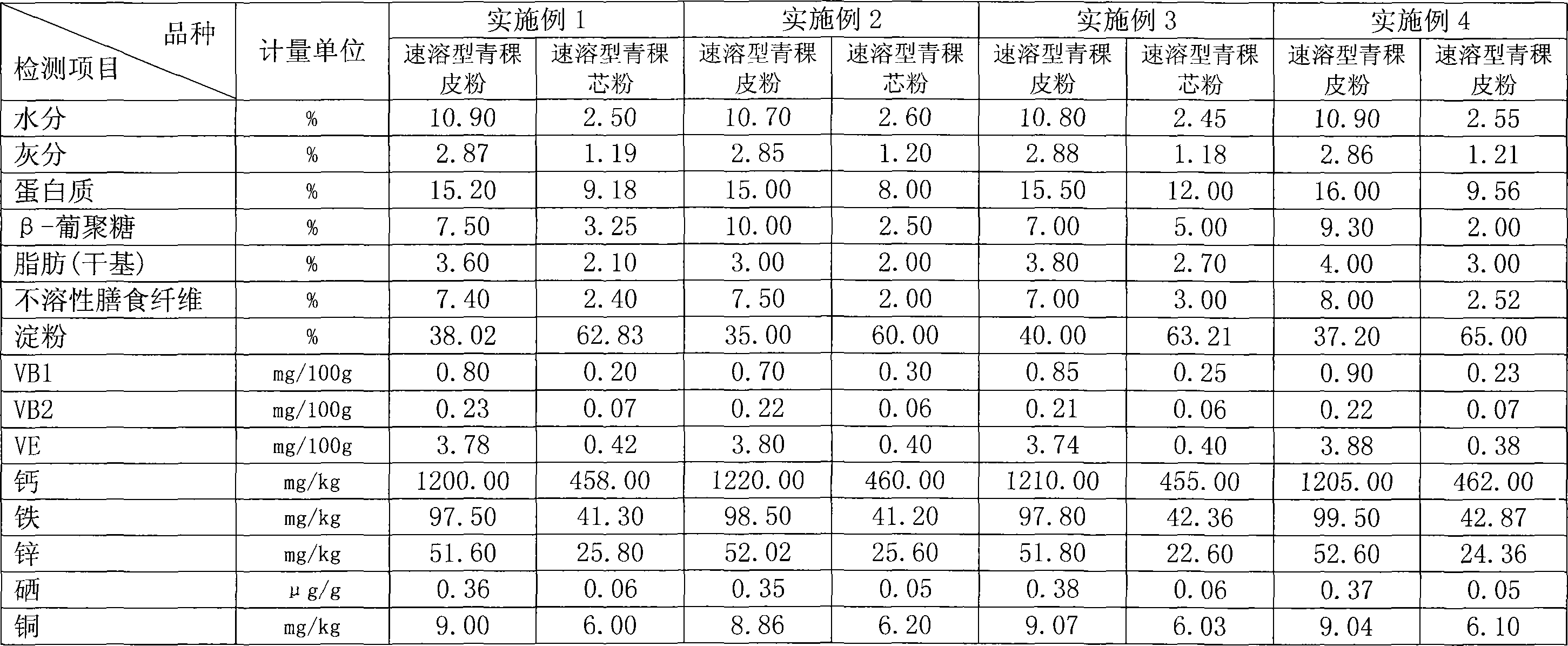

Embodiment 1

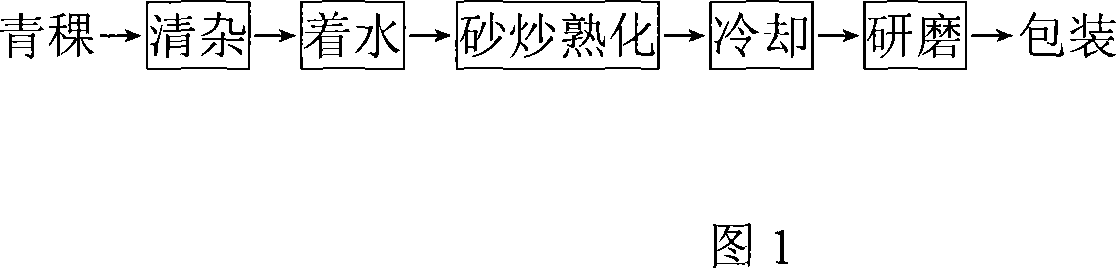

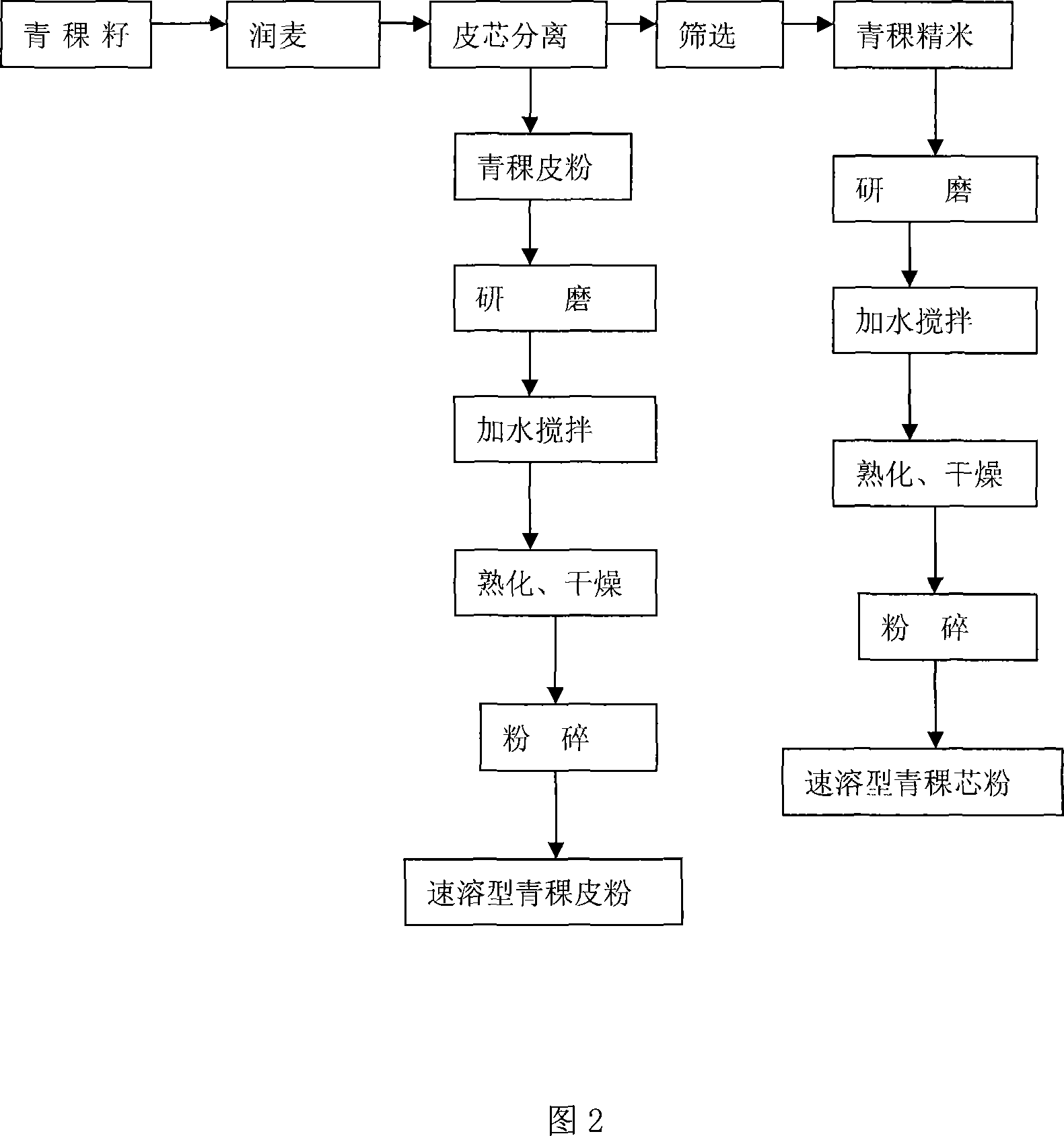

[0037] Embodiment 1: the deep processing method of highland barley

[0038] 1. Wash 5Kg of highland barley, remove sand, dust, straw and other sundries, moisten the wheat for 20 minutes, and then send it to the sheller to separate the skin and heart;

[0039] 2. Use a 3.8mm sieve to screen the polished highland barley rice for the first time. The highland barley grains under the sieve surface are directly used as polished highland barley rice, and then the large highland barley grains on the sieve surface are re-separated from the skin and core, and the process is repeated until all the highland barley grains pass through the sieve. Net, the color of the highland barley polished rice obtained is white, contains part of highland barley hypocotyls, and has no germ; the rest is highland barley rough skin powder; wherein highland barley polished rice 2.3Gg highland barley rough skin powder 2.3Kg;

[0040] 3. Grinding highland barley polished rice (or highland barley coarse husk po...

Embodiment 2

[0043] Embodiment 2: the deep processing method of highland barley

[0044] 1. Wash 5Kg of highland barley, remove sand, dust, straw and other sundries, and moisten the wheat for 40 minutes;

[0045] 2. Sending into a roller mill and separating the skin and heart to obtain 3.3Kg of highland barley fine-grained powder and 1.5Kg of highland barley coarse-grained powder;

[0046] 3. Grinding the highland barley fine-grained powder and the highland barley coarse-grained powder into fine powder respectively;

[0047] 4. Use clean tap water to stir the highland barley heart powder (or highland barley skin powder) evenly into a paste;

[0048] 5. Send the well-stirred highland barley heart powder (or highland barley skin powder) into the screw extrusion extruder respectively for expansion (temperature 120-150°C, working pressure in the extruder 0.8-1.0Mpa, feed moisture 7%-15 %, 200-250r / min), dry, and then go through ultrafine pulverization until all pass through 100 meshes and pack...

Embodiment 3

[0049] Embodiment 3: the production method of instant type highland barley barley powder and instant type highland barley heart powder

[0050] 1. Wash 5Kg of highland barley, remove sand, dust, straw and other sundries, fry the highland barley with sand frying method, obtain 4.5Kg of cooked highland barley grains, and then send them to the sheller for separation of skin and core;

[0051] 2. Use a 4.2mm sieve to screen the highland barley polished rice for the first time. The highland barley grains under the sieve surface are directly used as highland barley core grains, and then the large highland barley grains on the sieve surface are re-separated from the skin and core, and the process is repeated until all the highland barley grains pass through. Sieve; the rest is highland barley barley powder; of which highland barley heart grains are 2.4Kg, and highland barley coarse barley powder accounts for 2Kg;

[0052] 3. Grinding the highland barley fine-grained powder and the hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com