Preparation method of beta-glucan-rich tricholoma matsutake yoghurt tablets

A technology for yogurt tablets and glucan, which is applied in the directions of milk preparations, bacteria and dairy products used in food preparation, can solve the problems of affecting the original flavor of milk tablets, unable to satisfy consumers, etc., and improve the human intestinal tract. function, improve immunity, improve the effect of intestinal flora

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

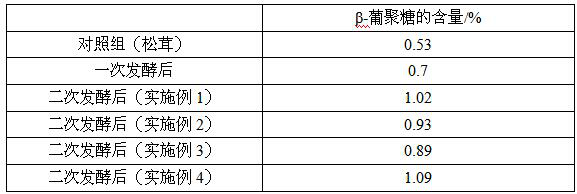

Examples

Embodiment 1

[0025] A preparation method of matsutake yogurt slices rich in β-glucan, comprising the steps of:

[0026] (1) Select 500g matsutake fruiting bodies, wash, dry and crush, then add 2000ml containing 10 strains 6 cfu / ml-10 7 cfu / ml Saccharomyces cerevisiae malt extract powder culture solution, cultured at 20°C for 26 hours and then filtered;

[0027] (2) Add 80g of milk powder to the filtered filtrate in step (1), add Lactobacillus bulgaricus for fermentation, ferment at 28°C for 15 hours, freeze-dry to obtain yogurt bacteria powder;

[0028] (3) Weigh 95g of the yogurt bacteria powder obtained in step (2), add 5g of white sugar and mix evenly, quickly granulate with ethanol with a volume ratio concentration of 80%, and immediately put it in an electric blast drying oven not higher than 55°C Dry, when the water content is 2%-3%, pass through a 20-mesh sieve and directly press into tablets.

Embodiment 2

[0030] A method for preparing yogurt slices rich in matsutake oligosaccharides, comprising the steps of:

[0031] (1) Select 500g matsutake fruiting bodies, wash, dry and crush, then add 2000ml containing 10 strains 6 cfu / ml-10 7 cfu / ml Saccharomyces cerevisiae malt extract powder culture solution, cultured at 37°C for 24 hours and then filtered;

[0032] (2) Add 80 g of milk powder to the filtered filtrate in step (1), add Bifidobacterium lactis to ferment, ferment at 32°C for 12 hours, and freeze-dry to obtain yogurt bacteria powder;

[0033] (3) Weigh 95g of the yogurt bacteria powder obtained in step (2), add 5g of xylitol and mix evenly, quickly granulate with ethanol with a volume ratio concentration of 75%, and immediately put it into an electric blast drying oven not higher than 55°C When the water content is 2%-3%, pass through a 20-mesh sieve and directly press into tablets.

Embodiment 3

[0035] A method for preparing yogurt slices rich in matsutake oligosaccharides, comprising the steps of:

[0036] (1) Select 500g matsutake fruiting bodies, wash, dry and crush, then add 2000ml containing 10 strains 6 cfu / ml-10 7 cfu / ml Saccharomyces cerevisiae malt extract powder culture solution, cultured at 38°C for 22 hours and then filtered;

[0037] (2) Add 80 g of milk powder to the filtrate filtered in step (1), add Streptococcus thermophilus, and ferment, ferment at 37°C for 8 hours, and freeze-dry to obtain yogurt bacteria powder;

[0038] (3) Weigh 91g of the yogurt bacteria powder obtained in step (2), add 9g of erythritol and mix evenly, quickly granulate with ethanol with a volume ratio concentration of 80%, and immediately put it into an electric blast drying at no higher than 55°C Dry in the box, and when the moisture content is 2%-3%, pass through a 20-mesh sieve and directly press into tablets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com