1CdS, CdSe or CdTe hollow Nano ring, and preparation method

A hollow nano- and nano-ring technology, applied in the fields of nanostructure manufacturing, nanotechnology, nanotechnology, etc., to achieve the effects of easy availability of raw materials, simple raw materials and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] The preparation of embodiment 1.CdTe hollow nano ring

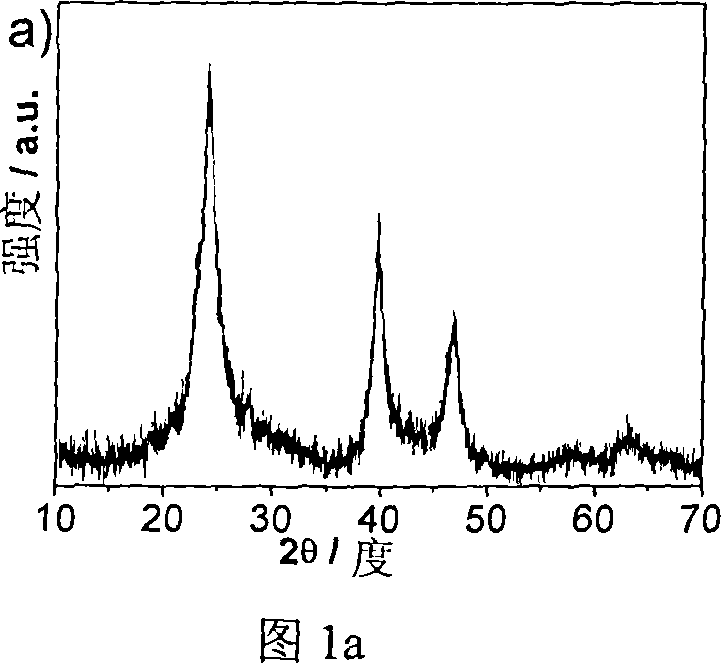

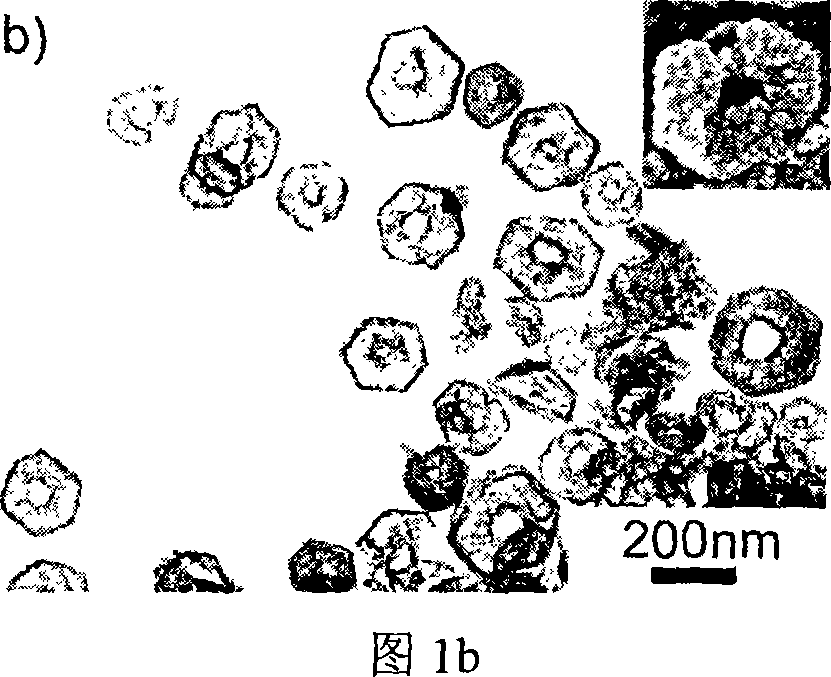

[0015] 1.5mmol Cd(OH) 2 Add nanorings to 30ml aqueous solution containing 1.5mmol NaHTe, stir and react for 20 minutes under nitrogen protection, centrifuge the product, wash the precipitate with distilled water and ethanol in sequence, and then dry the obtained precipitate in an oven at 60°C . The XRD measurement results (see accompanying drawing 1a) show that the product is pure cubic phase CdTe, and no heterophase peaks are found, indicating that the product has a relatively high purity. Through the TEM photo (accompanying drawing 1b), it is observed that the CdTe ring product has a hexagonal shape, an outer diameter of 200-260 nanometers, an inner diameter of 50-70 nanometers, and a hollow structure inside the ring body. The scanning electron microscope illustration in the accompanying drawing b can be clearly seen The see interior is hollow.

Embodiment 2

[0016] The preparation of embodiment 2.CdTe hollow nano rings

[0017] Cd(OH) 2 The amount of nanorings and NaHTe was changed to 6 mmol, the volume of the aqueous solution was 30 ml, and the other preparation conditions were the same as in Example 1. A product similar in crystal structure and morphology to Example 1 was obtained.

Embodiment 3

[0018] The preparation of embodiment 3.CdTe hollow nano rings

[0019] The reaction time was changed to 30 minutes, and other conditions of preparation were the same as in Example 1. A product similar in crystal structure and morphology to Example 1 was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com