New technique for producing lactic acid through solid state fermenting dregs of potato by rhizopus of rice

A technology of solid-state fermentation and Rhizopus oryzae, applied in the directions of fermentation, microorganisms, microorganism-based methods, etc., can solve the problems such as the production of lactic acid by solid-state fermentation of potato residues of Rhizopus oryzae, which can save energy consumption, reduce production costs, The effect of promoting reproduction and accumulation of lactic acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

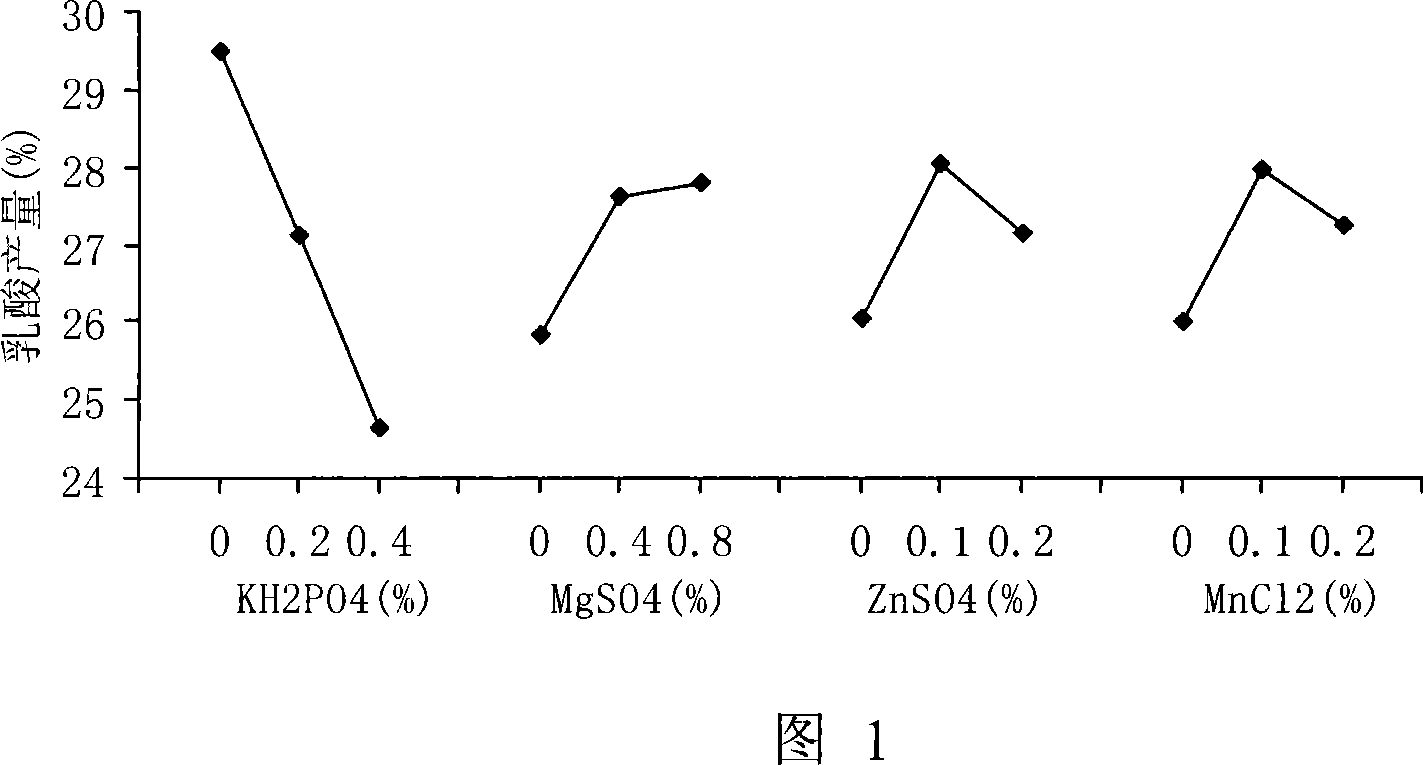

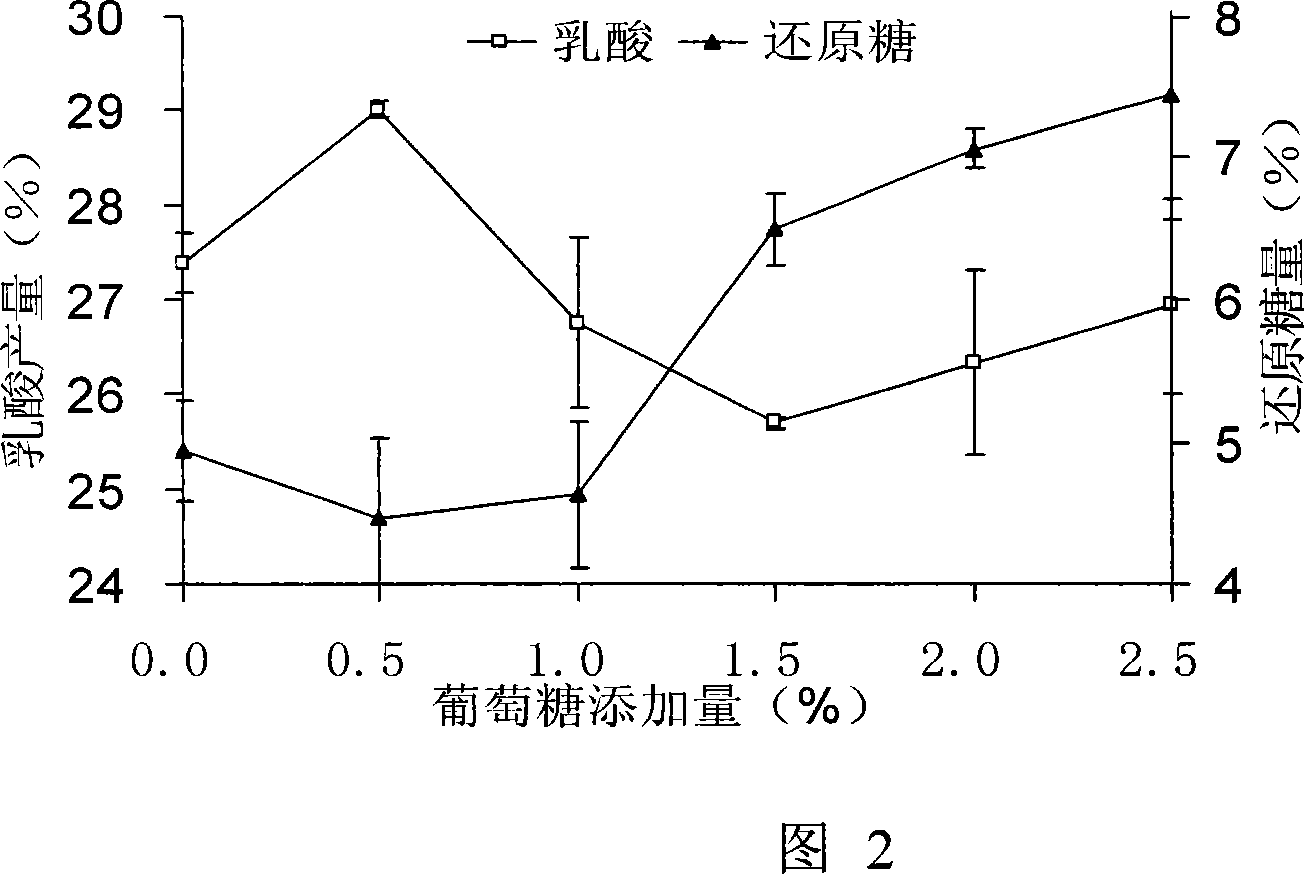

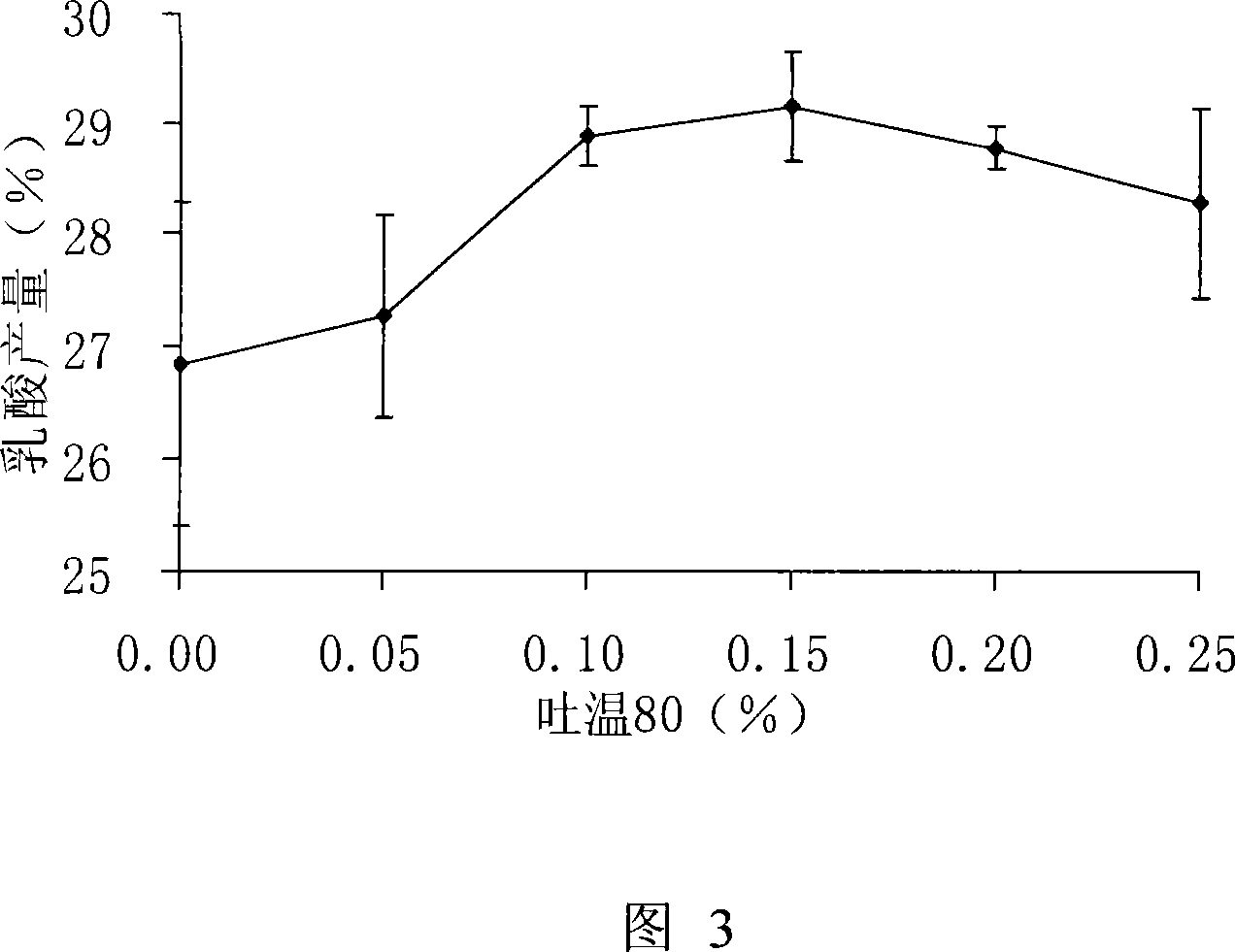

Method used

Image

Examples

example 1

[0041] Rhizopus oryzae PW352 slant seed culture: culture at 36°C for 3 days; solid-state fermentation culture: routine high-temperature sterilization of the medium, inoculation of 1-2ml spore suspension (1×10 7 spores / ml), stirred evenly, and cultivated at 34°C for 3 days, and the fermentation vessel was a 250ml Erlenmeyer flask.

[0042] The solid-state fermentation medium consists of: 10 g of sweet potato residue, and the weight percentages of all the other components in sweet potato residue are as follows: KH 2 PO 4 0%, MgSO 4 0.60%, ZnSO 4 0.15%, MnCl 2 0.15%, calcium carbonate addition 20%, glucose 1.0%, nitrogen source selection 2.0% (NH 4 ) 2 SO 4 , Tween 80 0.10%, add 66-70% water of the total weight of the above components, and the pH is natural.

[0043] The amount of L-lactic acid produced after 72 hours of fermentation reached 31.71 (±0.72)% (w / w) of the weight of sweet potato residue, and the conversion rate of starch sugar was 57.38% (±1.30).

example 2

[0045] Seed preparation and solid-state fermentation conditions are the same as Example 1, and the fermentation container is a 250ml Erlenmeyer flask.

[0046] The components of the solid-state fermentation medium are: sweet potato residue 10g, ZnSO 4 0.20%, MgSO 4 0.80%, MnCl 2 0.20%, calcium carbonate added 20%, glucose 0.50%, (NH 4 ) 2 SO 4 2.5%, Tween 80 0.15%, add 70% water of the total weight of the above components, and the pH is natural.

[0047] The amount of L-lactic acid produced by fermentation for 72 hours reached 28.74 (±0.48)% (w / w) of the weight of sweet potato residue, and the conversion rate of starch sugar was 52.01%.

example 3

[0049] Seed preparation and solid-state fermentation conditions are the same as Example 1, and the fermentation container is a 250ml Erlenmeyer flask.

[0050] The components of the solid-state fermentation medium are: sweet potato residue 10g, KH 2 PO 4 0.4%, ZnSO 4 0.1%, MgSO 4 0.8%, MnCl 2 0%, calcium carbonate addition 20%, glucose 0.5%, (NH 4 ) 2 SO 4 2.0%, Tween 80 0.20%, add 70% water of the total weight of the above components, the pH is natural.

[0051] The amount of L-lactic acid produced by fermentation for 72 hours reached 24.77 (±0.43)% (w / w) of the weight of sweet potato residue, and the conversion rate of starch sugar was 44.82% (±0.78).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com