Detecting device and method for pipeline wall thickness

A detection device and detection method technology, applied in the field of ultrasonic detection, can solve the problems of high cost, complex structure, opening holes, etc., and achieve the effect of convenient operation, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

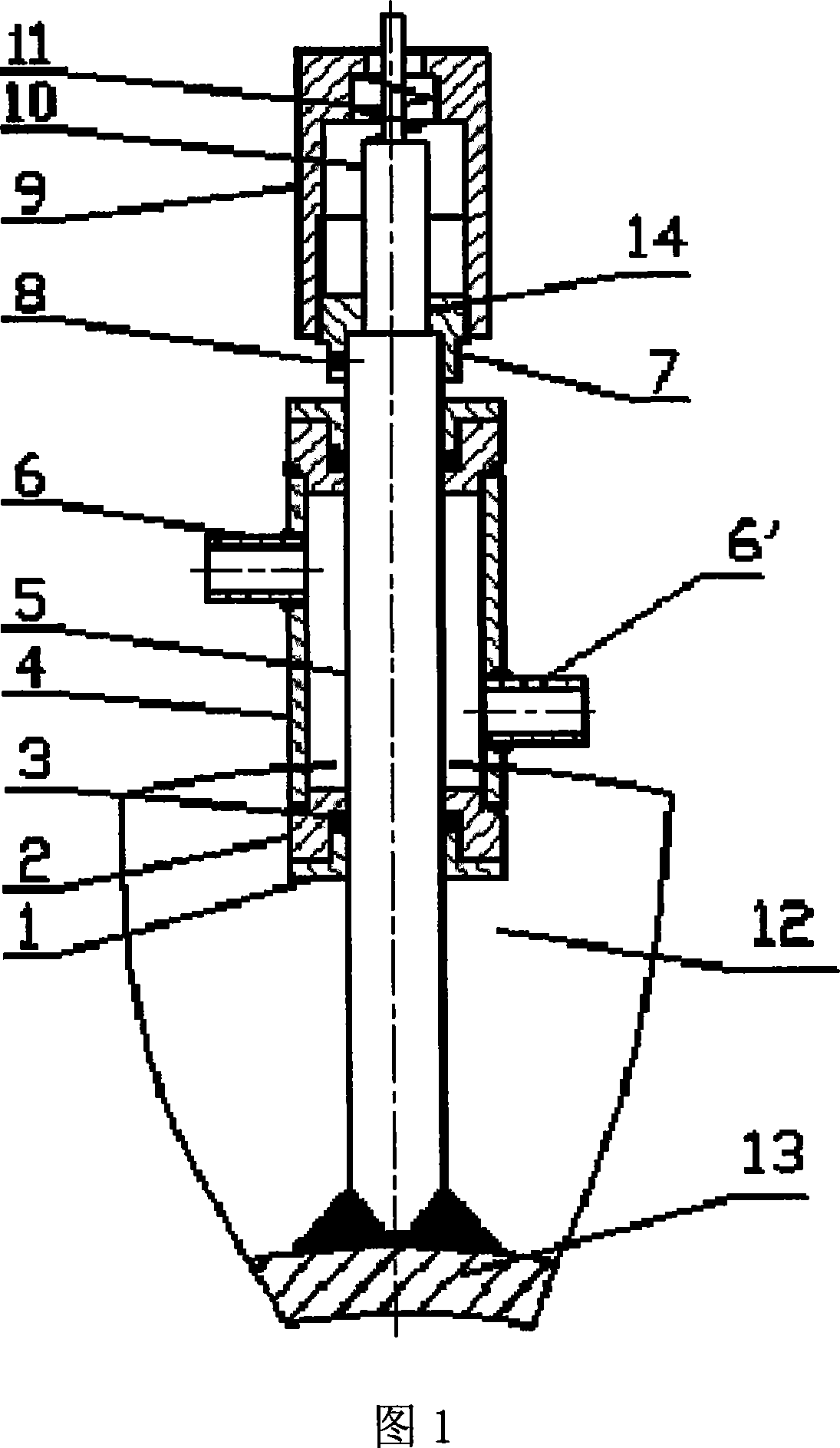

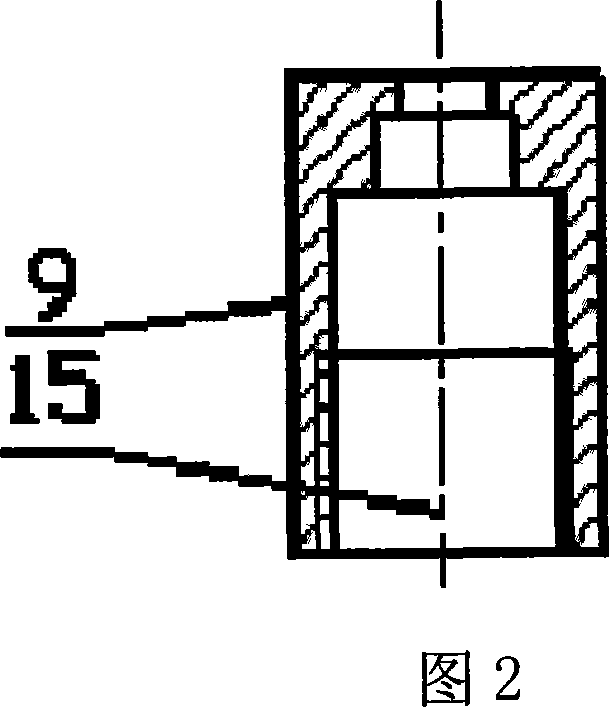

Embodiment 1

[0032] The lower end of the measuring rod 5 is welded on a flat circular plate (simulated pipeline). Both the measuring rod 5 and the circular plate are made of 20 steel. The diameter of the measuring rod 5 is 19 mm, the length is 150 mm, and the surface is sprayed with 1Cr18Ni9Ti stainless steel coating. Coating thickness 0.5mm. After calibration, the selected ultrasonic velocity is 5800 m / s; the thickness of the selected circular plate measured by a precision caliper is 15.7 millimeters, and the measuring rod 5 is welded on the circular plate with the welding rod of the same material. After welding, the upper end surface of the measuring rod to The distance between the upper surface of the circular plate is 151.4mm (including the weld seam of 1.4mm). Fix the probe positioning block 7 with the countersunk head screw 8 at 4-6 mm from the end of the measuring rod 5, place the probe 10 in the central stepped hole 15 of the probe positioning block 7, and fit the upper end of the ...

Embodiment 2

[0035] Based on Example 1, a cooling assembly is installed in the middle of the measuring rod 5; the sleeve 5 is a seamless steel pipe with an outer diameter of 57mm and a wall thickness of 3.5mm, equipped with an end cover 2 and a gland 1, and on the sleeve 5 The water inlet pipe interface 6 and the water outlet pipe interface 6' of the cooling water are set on the wall of the cylinder, and the cooling water circulation system is connected externally, and the cooling length is designed to be 50mm; Water flow 25m 3 / h, the temperature of the end surface of the measuring rod 5 is 40°C; in order to calibrate the sound velocity of the system under this temperature environment, set the sound velocity so that the measured H value is 15.7mm (remaining the same as implementation 1). Then, another set of testing devices with the same size welded measuring rods but with a circular plate thickness of 19.5 mm is installed with the same water circulation cooling system and heating system....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Total length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com