Detection device for panel display test and its production method

A flat-panel display and detection device technology, applied in measuring devices, clothing, applications, etc., can solve problems such as short circuit, decreased accuracy, and poor electromechanical characteristics, and achieve the effects of eliminating noise, reducing failure rate, and suppressing misoperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Next, preferred embodiments of the present invention will be described with reference to the accompanying drawings. However, the embodiments of the present invention can be changed in various other forms, and it should not be construed that the scope of the present invention is limited only to the embodiments described below.

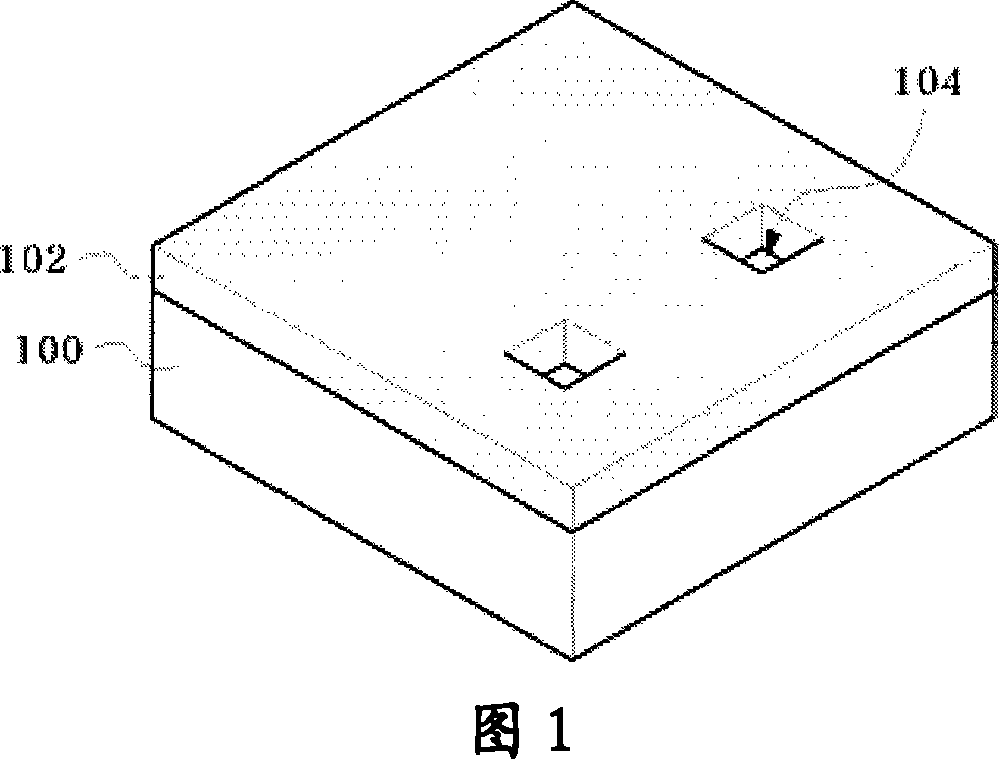

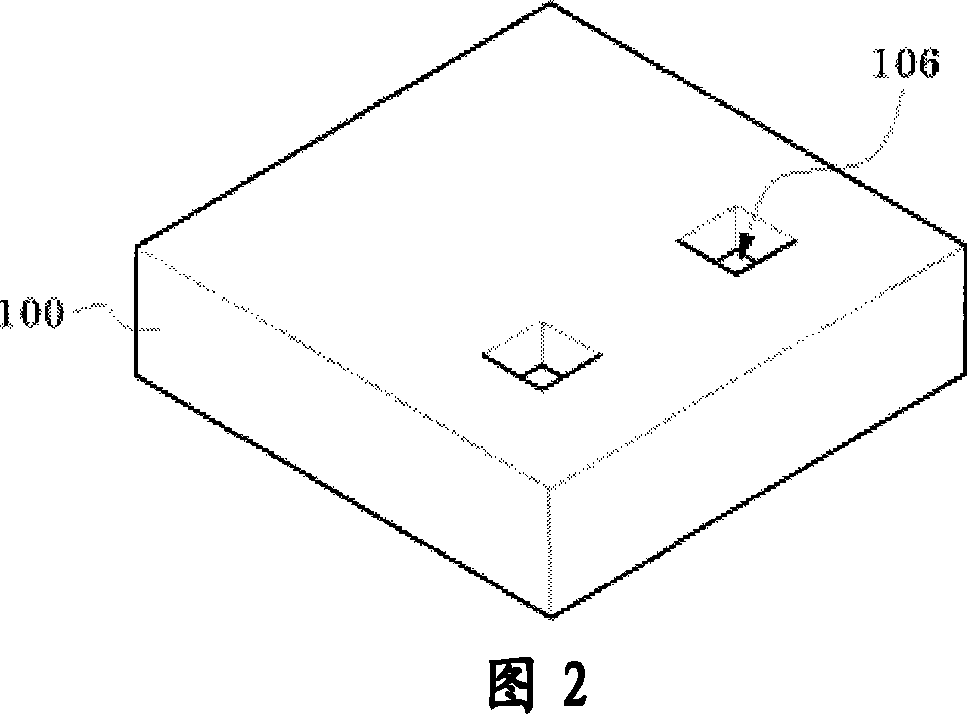

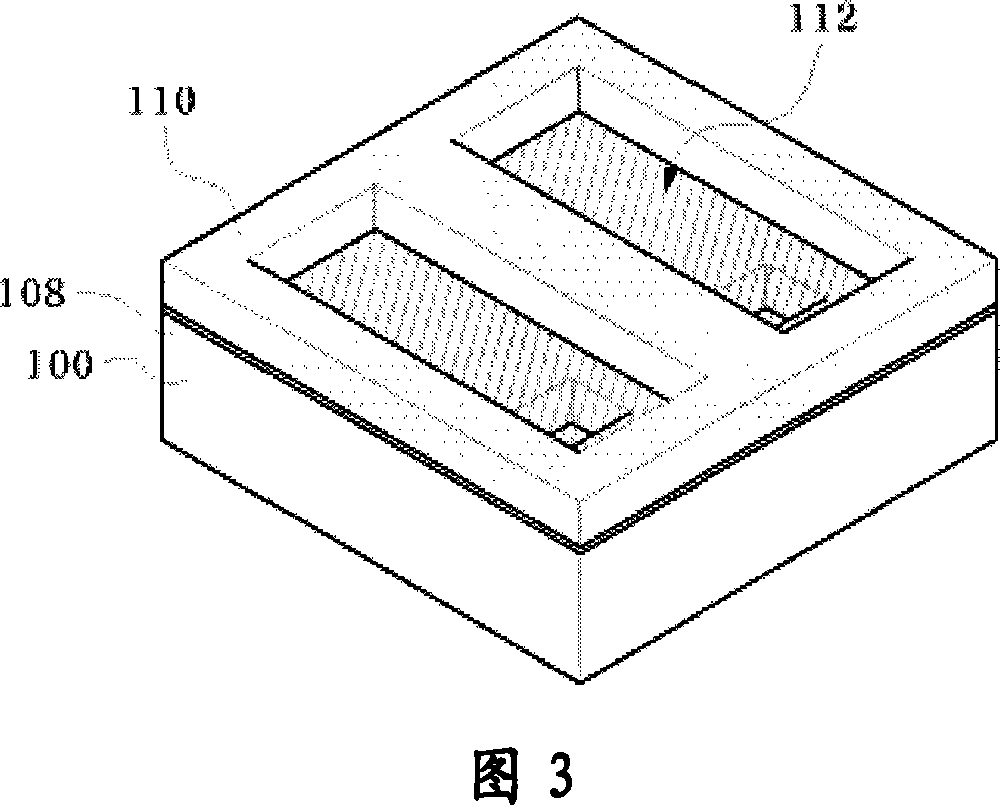

[0037]1 to 8 are perspective views illustrating a flat panel display testing device and a manufacturing method thereof according to an embodiment of the present invention.

[0038] First, as shown in FIG. 1 , a first mask pattern 102 is formed on a substrate 100 . The substrate 100 may be a silicon substrate. The first mask pattern 102 can be formed by exposure and development steps by photolithography. The first mask pattern 102 has an opening 104 through which a part of the surface of the substrate 100 , that is, the surface of the portion for forming the trench is exposed. Next, etching is performed using the first mask pattern 102 as an et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com