Methods of processing a substrate with minimal scalloping

An optimization and pressure technology, applied in the direction of circuits, processes for producing decorative surface effects, decorative arts, etc., can solve problems such as the influence of physical characteristics of synthetic devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

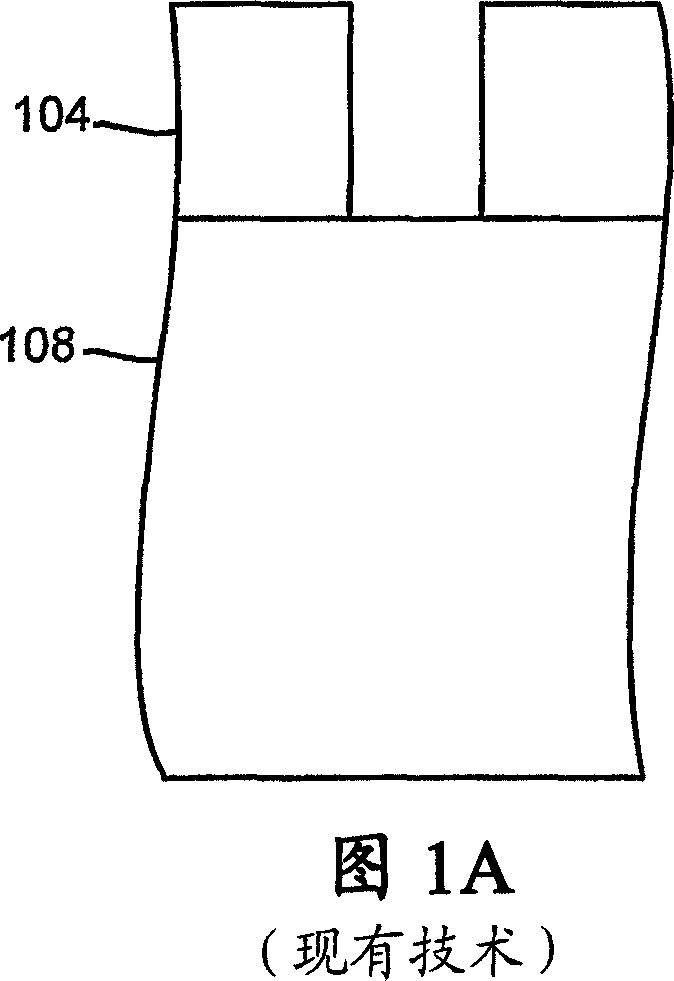

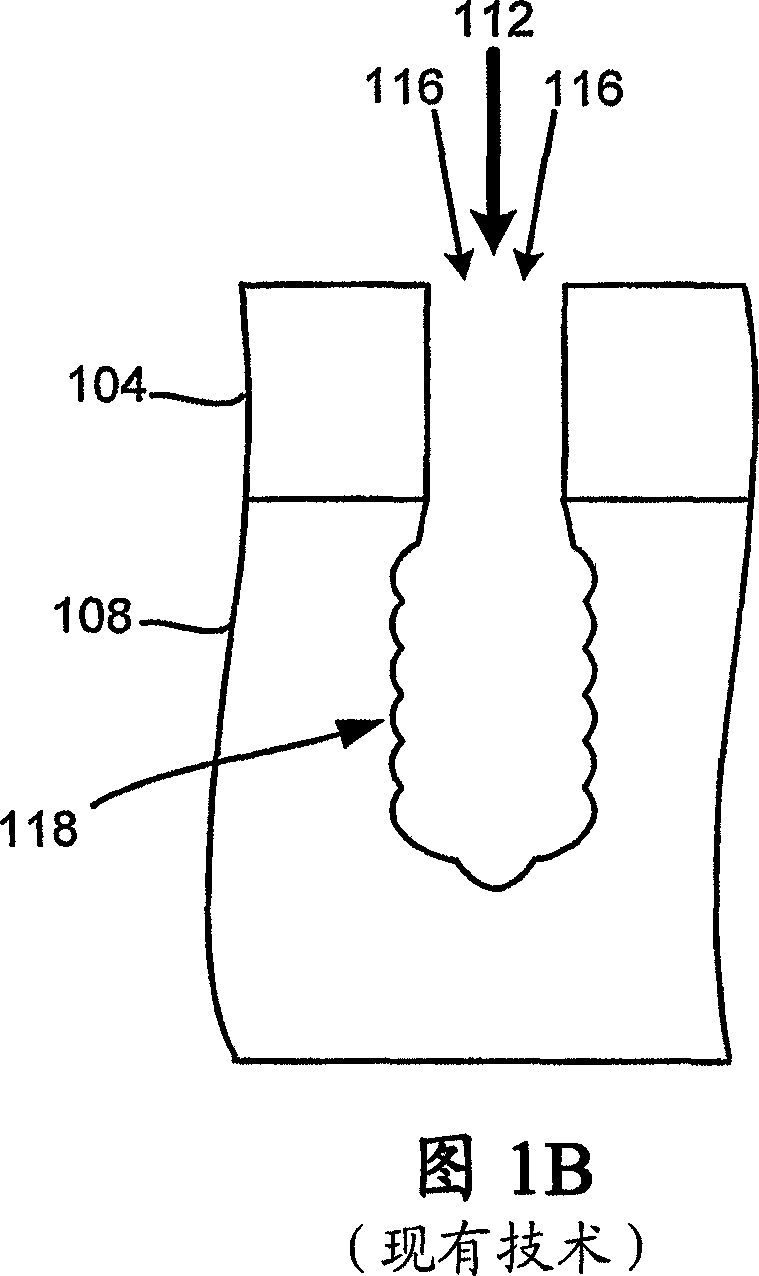

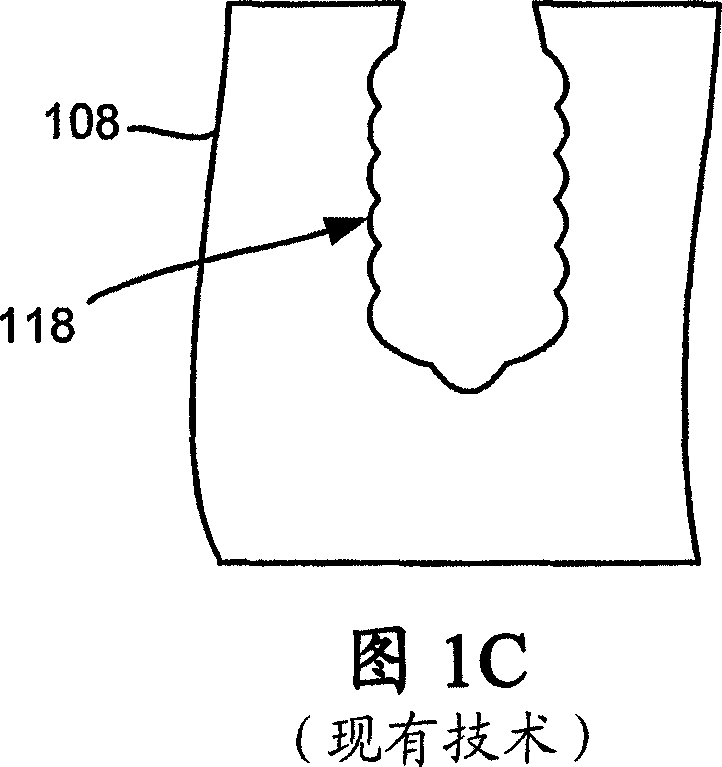

[0022] The method achieves advantages in etching the sidewall profile of the substrate. Specifically, scalloping is minimized during etching of crystalline silicon substrates, epitaxial silicon, polysilicon, amorphous silicon, and other suitable layers.

[0023] Method: Determining Optimal Process Parameters

[0024] In general, the entire etching process may include multiple cycles (eg, tens, hundreds, or more) of deposition sub-processes and etching sub-processes. It is believed that rapid switching between the deposition sub-process and the etch sub-process helps to avoid or substantially reduce scalloping in the resulting etch profile. Furthermore, it is believed that adjusting the overall etch process such that the chamber pressures during the etch sub-process and the deposition sub-process are substantially equal or as close as possible can be very helpful in avoiding or substantially reducing scalloping in the resulting etch profile. texture.

[0025] In the followin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com