Sterilized micro nano-silver film having nonpoisonous and the process thereof

A manufacturing method and technology of antibacterial film, applied in application, printing, ink and other directions, can solve the problems of inability to cope with toxicity, limited application field, no temperature sensing, photosensitive and fragrance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

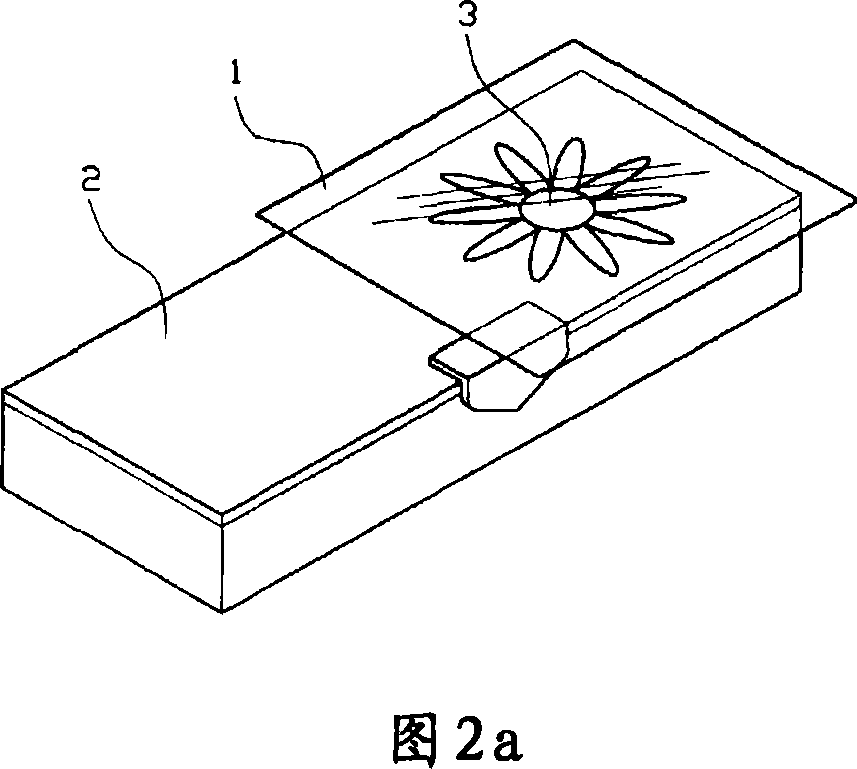

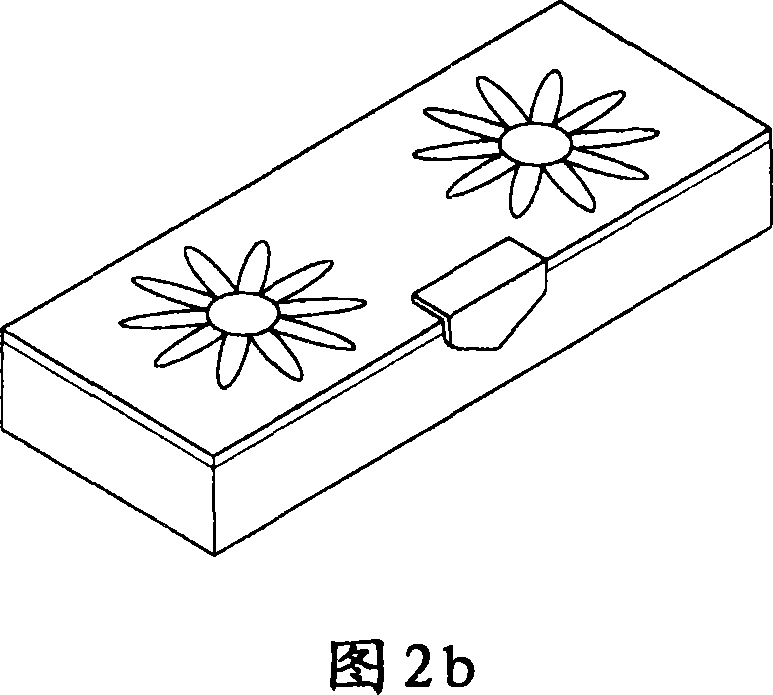

[0011] Beneficial embodiments of the present invention will be described in further detail below with reference to the accompanying drawings.

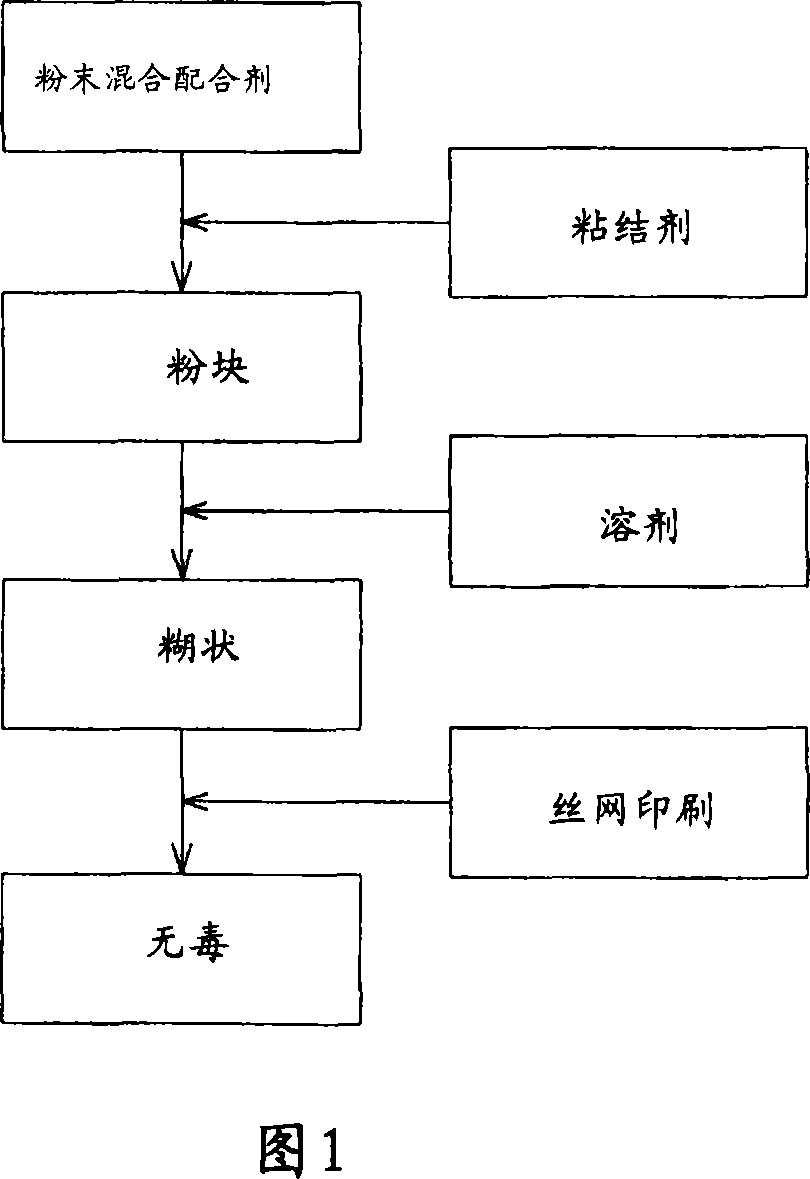

[0012] Fig. 1 is the process block diagram showing the manufacturing process of the non-toxic ultrafine nano-silver antibacterial film of the present invention.

[0013] As shown in the accompanying drawings, the present invention includes 4 processes, and the 1st process is to mix antibacterial agent powder, temperature-sensitive or photosensitive ink capsule powder, aromatic agent capsule powder and nano-silver powder and additives to manufacture powder mixed compounding agent.

[0014] Antimicrobial agent powder is used to inhibit bacterial growth, and it is sufficient to make well-known materials into powder form, for example, materials obtained from loess, antibacterial zeolite, or natural plant extracts.

[0015] Aromatic agent capsule powder is made of aromatic agents that emit fragrance, fruit, vanilla, coffee, etc. into powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com