Method for separating and purifying hydrophobin

A technology of hydrophobin and purification method, which is applied in the field of separation and purification of hydrophobin, can solve problems such as separation and purification difficulties, hinder development speed, and limited production capacity of hydrophobin, and achieve broad application prospects, easy industrial application, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1. Separation and purification of hydrophobin and detection of the influence of ultrasonic oscillation treatment with different powers on the purification effect

[0022] 1. Preparation of solid substrate with Teflon particles distributed on the surface for separation and purification of hydrophobin

[0023] Put the clean polished quartz substrate into the ion beam sputtering coating machine, install the Teflon target, vacuumize to 1.3E-3pa, take it out after sputtering for 5s, and obtain a solid substrate with Teflon particles distributed on the surface. The observation results of the atomic force microscope are shown in the figure 1 (the size of Figure A is 5 microns, and the size of Figure B is 1 micron), the surface roughness of the clean and polished quartz substrate is very low, and it can be seen from the atomic force image after sputtering that there are many particles distributed on the surface of the substrate. Particles, through the test of the water ...

Embodiment 2

[0026] Embodiment 2, the separation and purification of hydrophobin

[0027] 1. Preparation of solid substrate with Teflon particles distributed on the surface for separation and purification of hydrophobin

[0028] Put the clean glass substrate into the ion beam sputtering coating machine, install the Teflon target, vacuumize to 1.3E-3Pa, take it out after sputtering for 300s, and obtain a solid substrate with Teflon particles distributed on the surface.

[0029] 2. Separation and purification of hydrophobin

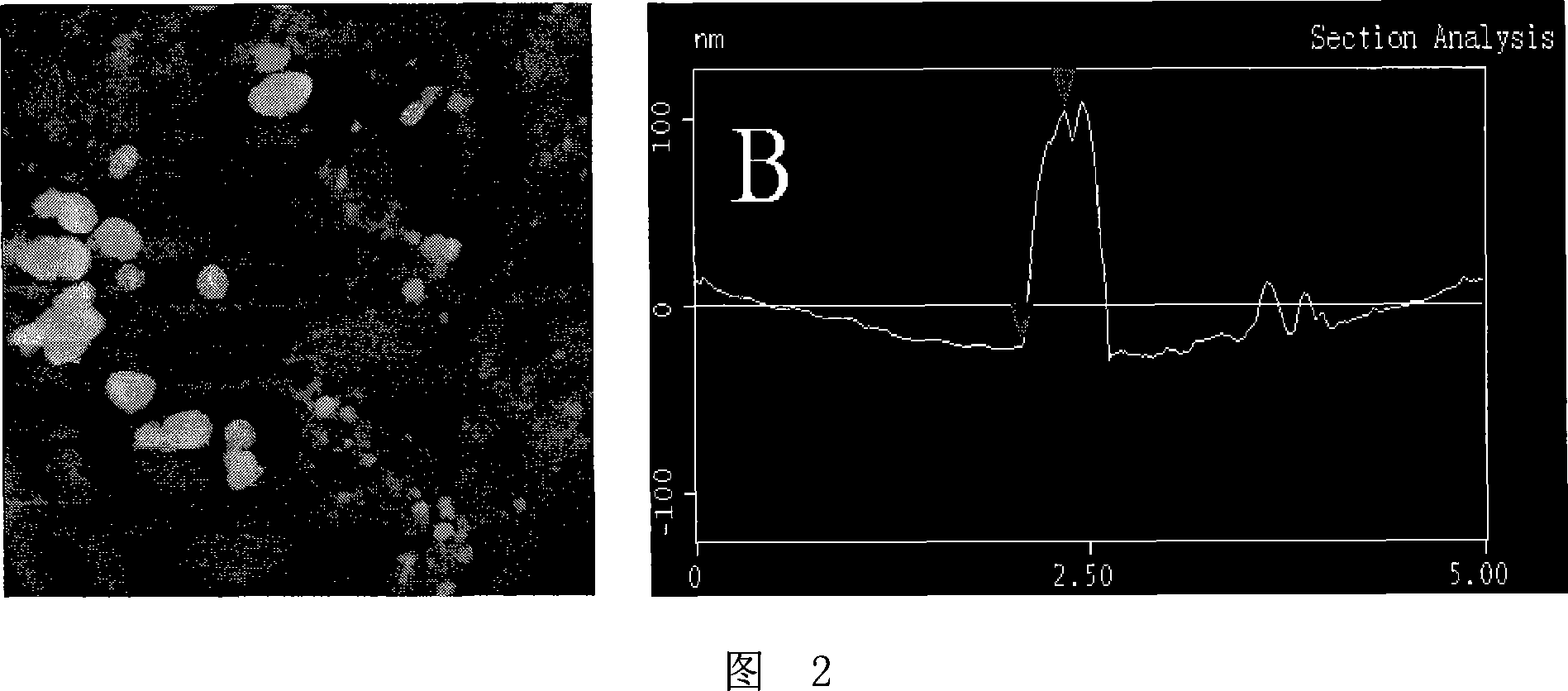

[0030] Put the solid substrate with Teflon particles distributed on the surface prepared in step 1 in the hydrophobin HFBII solution to be purified and soak for 72 hours, then take the substrate out of the hydrophobin solution, observe and analyze the image under an atomic force microscope, you can see Large irregular-shaped hydrophobin aggregates grew on the surface of the substrate, which was caused by the adsorption and nucleation of hydrophobin on the surface of Te...

Embodiment 3

[0031] Embodiment 3, the separation and purification of hydrophobin

[0032] 1. Preparation of solid substrate with Teflon particles distributed on the surface for separation and purification of hydrophobin

[0033] Put the clean glass substrate into the ion beam sputtering coating machine, install the Teflon target, vacuumize to 1.3E-3Pa, take it out after sputtering for 600s, and obtain a solid substrate with Teflon particles distributed on the surface.

[0034] 2. Separation and purification of hydrophobin

[0035] Soak the solid substrate with Teflon particles on the surface prepared in step 1 in the hydrophobin HFBII solution to be purified for 24 hours, then take the substrate out of the hydrophobin solution, observe and analyze the image under an atomic force microscope, you can see Large irregular-shaped hydrophobin aggregates grew on the surface of the substrate, which was caused by the adsorption and nucleation of hydrophobin on the surface of Teflon particles. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com