Integrated series-parallel combined electrolysis bath

An electrolytic cell and combined technology, applied in the field of electrolytic cells, can solve the problems of low utilization rate of electrode materials, many closed end faces of electrolytic cells, poor working conditions and parameters, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

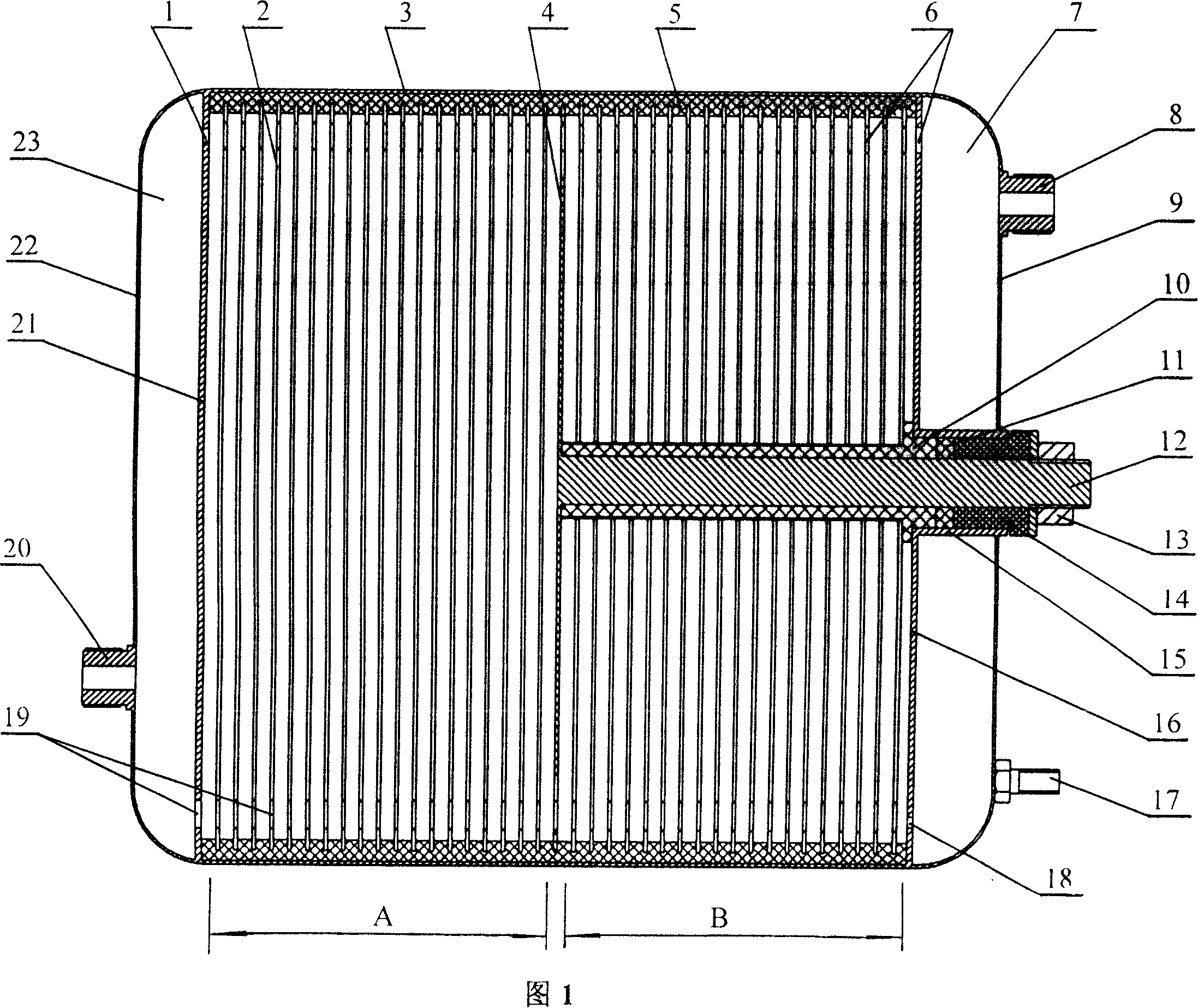

[0022] Embodiment 1 Referring to FIG. 1 , the insulating ring 5 is integral, and its inner ring is provided with equidistant ring grooves, and each ring groove has the same depth and thickness, and is used to embed the electrode sheet 2 . The liquid inlet 20 is welded at the bottom of the left end cover 22 , the gas-liquid outlet 8 is welded at the top of the right end cover 9 , and the cathode screw 17 is welded at the bottom of the right end cover 9 . The upper part of the left end plate 21 is provided with a guide hole 1, and the lower part is provided with a liquid guide hole 19. The upper part of the right end plate 16 is provided with an air guide hole 6, and the lower part is provided with a guide hole 18. The function of the guide holes is to strengthen the flow of liquid and prevent internal Impurities precipitate. A liquid buffer zone 23 and a gas-liquid buffer zone 7 are respectively formed between the end plates on both sides and the end covers on both sides. The ...

Embodiment 2

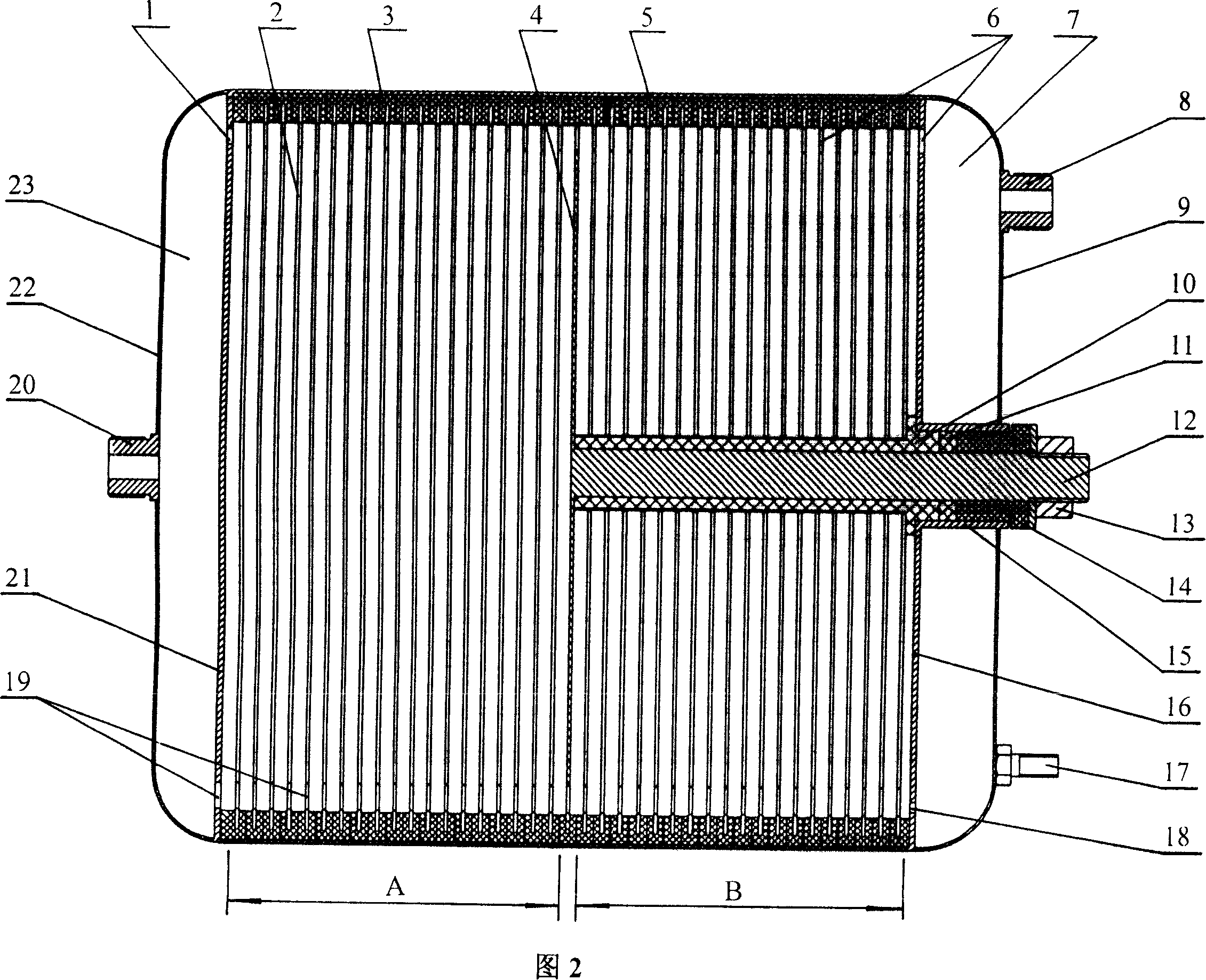

[0023] Embodiment 2 Referring to Fig. 2, the insulating ring 5 is multi-piece stacked, and the inner ring of each insulating ring is provided with equidistant annular grooves of the same specification, and the electrode sheets 2 are embedded. The liquid inlet 20 is welded in the middle of the left end cover 22, the gas-liquid outlet 8 is welded in the upper part of the right end cover 9, and the cathode screw 17 is welded in the lower part of the right end cover 9. The effects of the liquid buffer and the gas-liquid buffer of this scheme are the same as in Example 1.

Embodiment 3

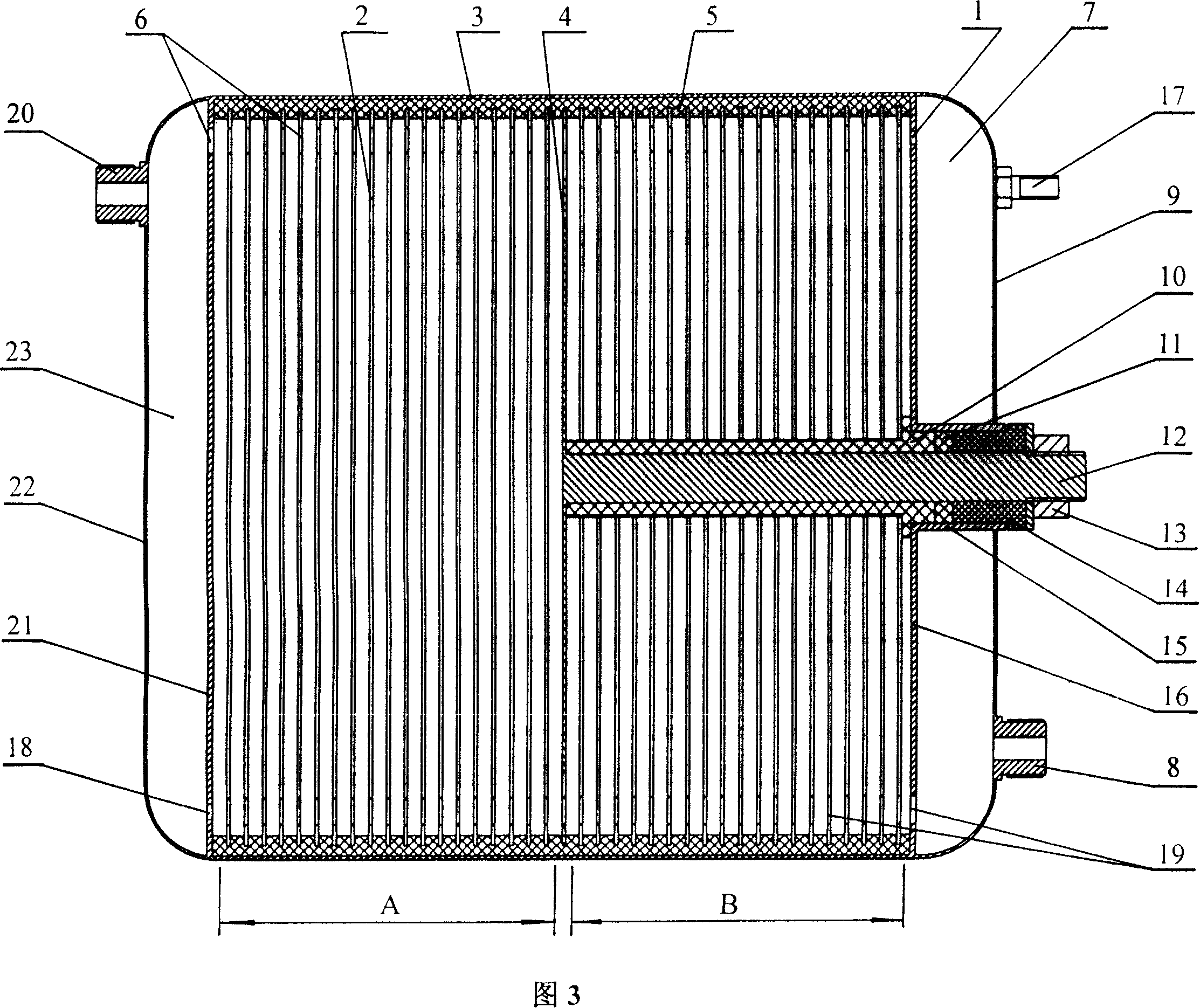

[0024] Referring to Fig. 3 for embodiment 3, the insulating ring 5 is the same as that of embodiment 1. The liquid inlet 20 is welded on the top of the left end cover 22 . The cathode screw 17 is welded on the upper part of the right end cover 9, and the gas-liquid outlet 8 is welded on the lower part of the right end cover 9. The liquid buffer of this scheme serves as a buffer for the liquid flowing out from the air guide hole and the guide hole, and the gas-liquid buffer serves as a buffer for the liquid flowing out of the guide hole and the liquid guide hole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com