Chain grate-rotary kiln preheating section single-side air draft process

A technology of grate and preheating section, which is applied in the field of improving the ventilation process of the preheating section of the grate, which can solve the problems of high power consumption, increased ventilation resistance, low strength of preheating balls and finished balls, and achieve reduction Effects of energy consumption, reduction of power consumption, investment and maintenance cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

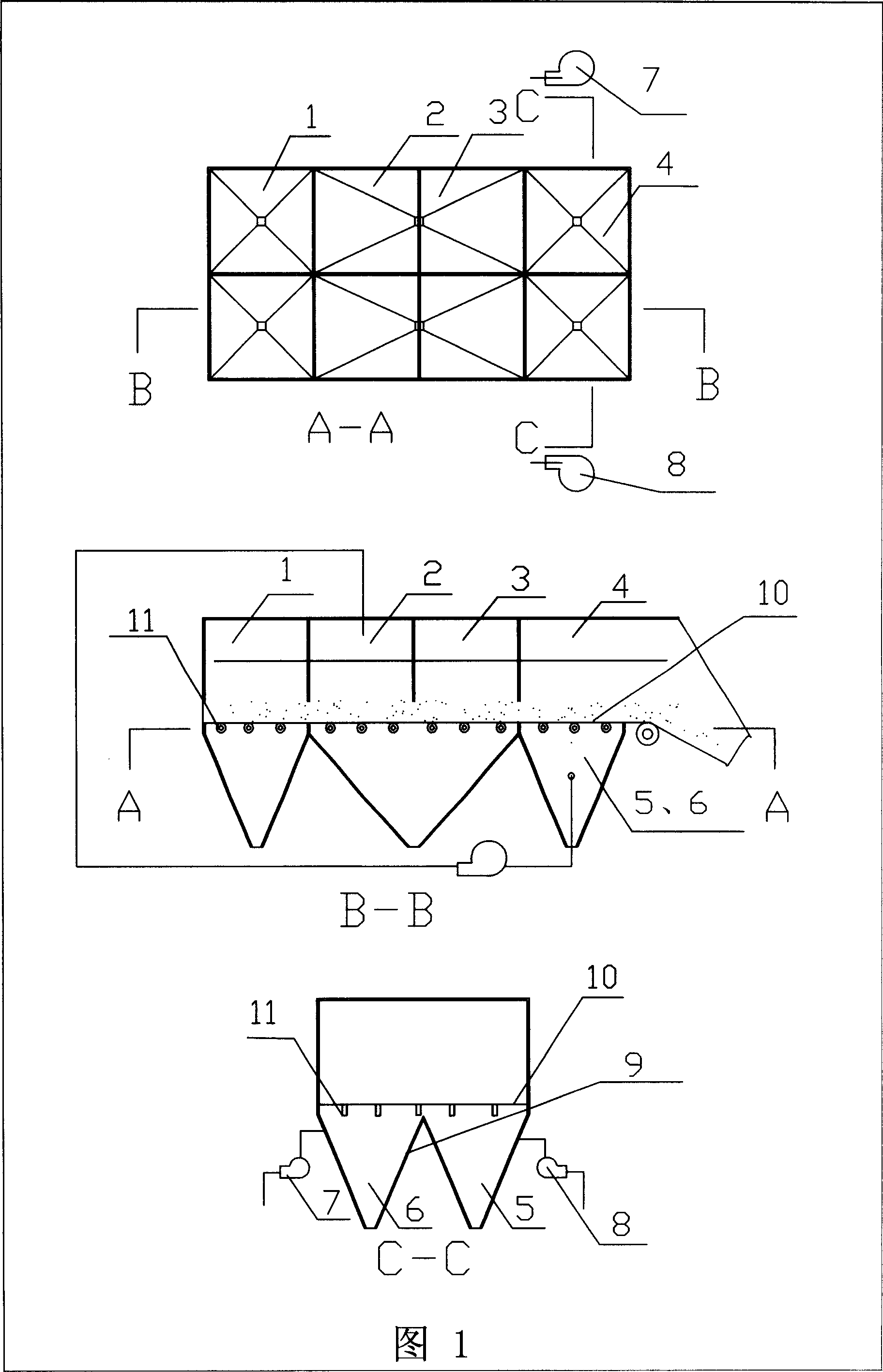

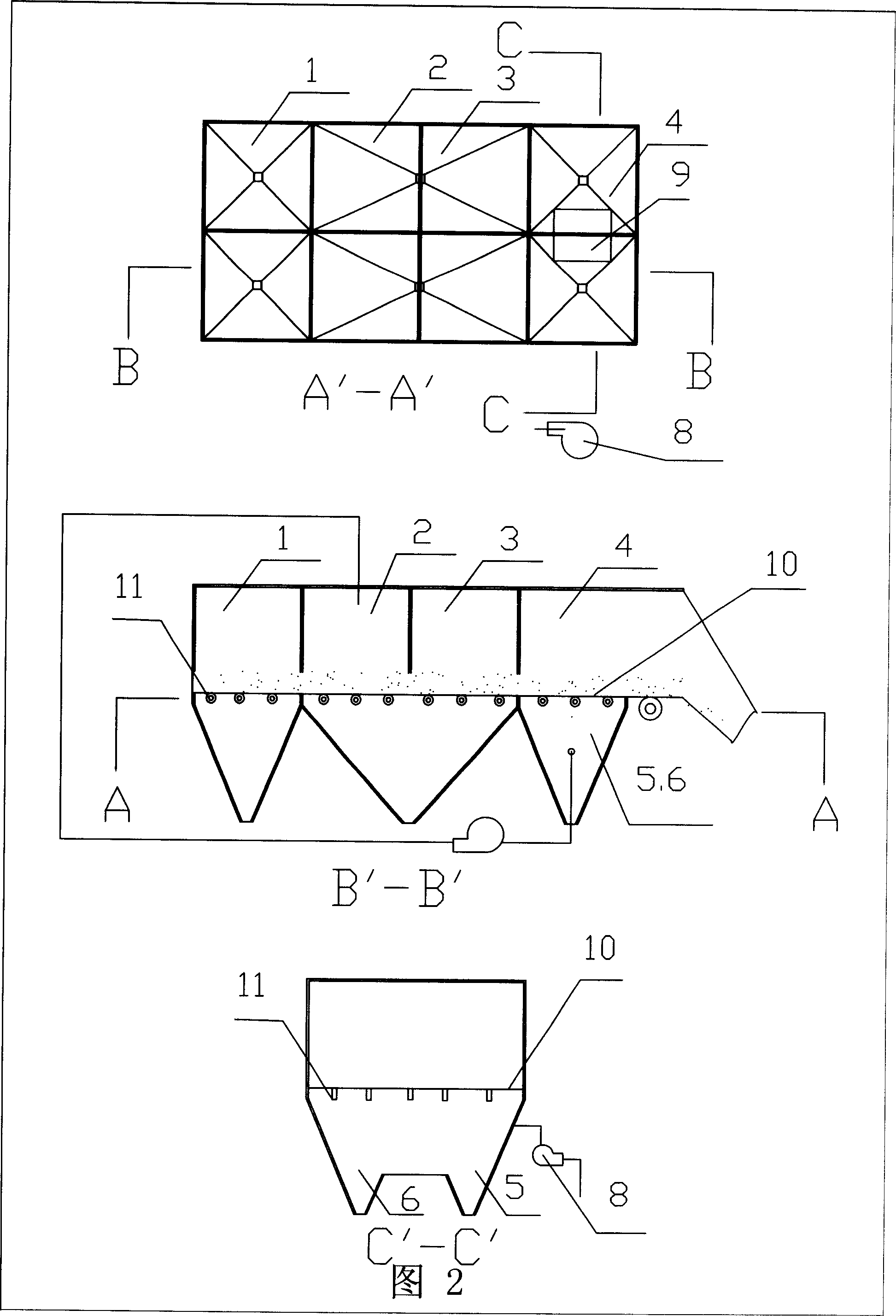

[0006] The schematic diagram of the exhaust process in the original preheating section is shown in Figure 1, and the schematic diagram of the modified process flow is shown in Figure 2. 1—blast drying section; 2—air drying section 1; 3—air drying section 2; 4—preheating section; 5—preheating section bellows; 6—preheating section bellows; 7—preheating Hot section exhaust fan; 8—preheating section exhaust fan; 9—the connection form of the bellows under the grate bed; 10—the grate bed; 11—the upper supporting wheel of the grate.

[0007] 1. Remove one of the two fans, expand the cross-section of the ventilation channel under the grate machine to be greater than or equal to the cross-sectional area of the total exhaust duct, see Figure C-C, cut 9 flat to increase the ventilation area, and the air box after transformation The internal structure is shown as C'-C'.

[0008] 2. The air volume of the fan is selected. Because one fan is used for air extraction, there is no turbulent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com