Sn-Zn series leadless solder alloy and its preparation method

A lead-free solder and alloy technology, used in metal processing equipment, manufacturing tools, welding equipment, etc., can solve the problems of poor wettability and easy oxidation, and achieve low cost, good wettability and excellent oxidation resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. Take LiCl and KCl respectively according to the mass ratio of LiCl: KCl component of 1.0: 1.3, a total of 10g, and mix them uniformly to prepare a protected molten salt;

[0032] 2. Take by weight respectively Zn is 8.0g (8%), Cu is 2.0g (2%) mixed rare earth RE is 0.05g (0.05%), all the other are Sn, gross weight 100%, quality is 100g altogether, And put them all into a graphite crucible and stir them into a uniform mixture, cover the mixture in the crucible with the prepared protective molten salt, put the crucible in a well-type vacuum furnace for melting, vacuumize and fill it with high Pure nitrogen, when the furnace temperature reaches 600°C, keep it warm for 60 minutes, after melting, take out the crucible, pre-cool and cast the alloy;

[0033] 3. Remelt the casted alloy above at 400°C, keep it warm for 50 minutes, stir, and finally cast it into an ingot.

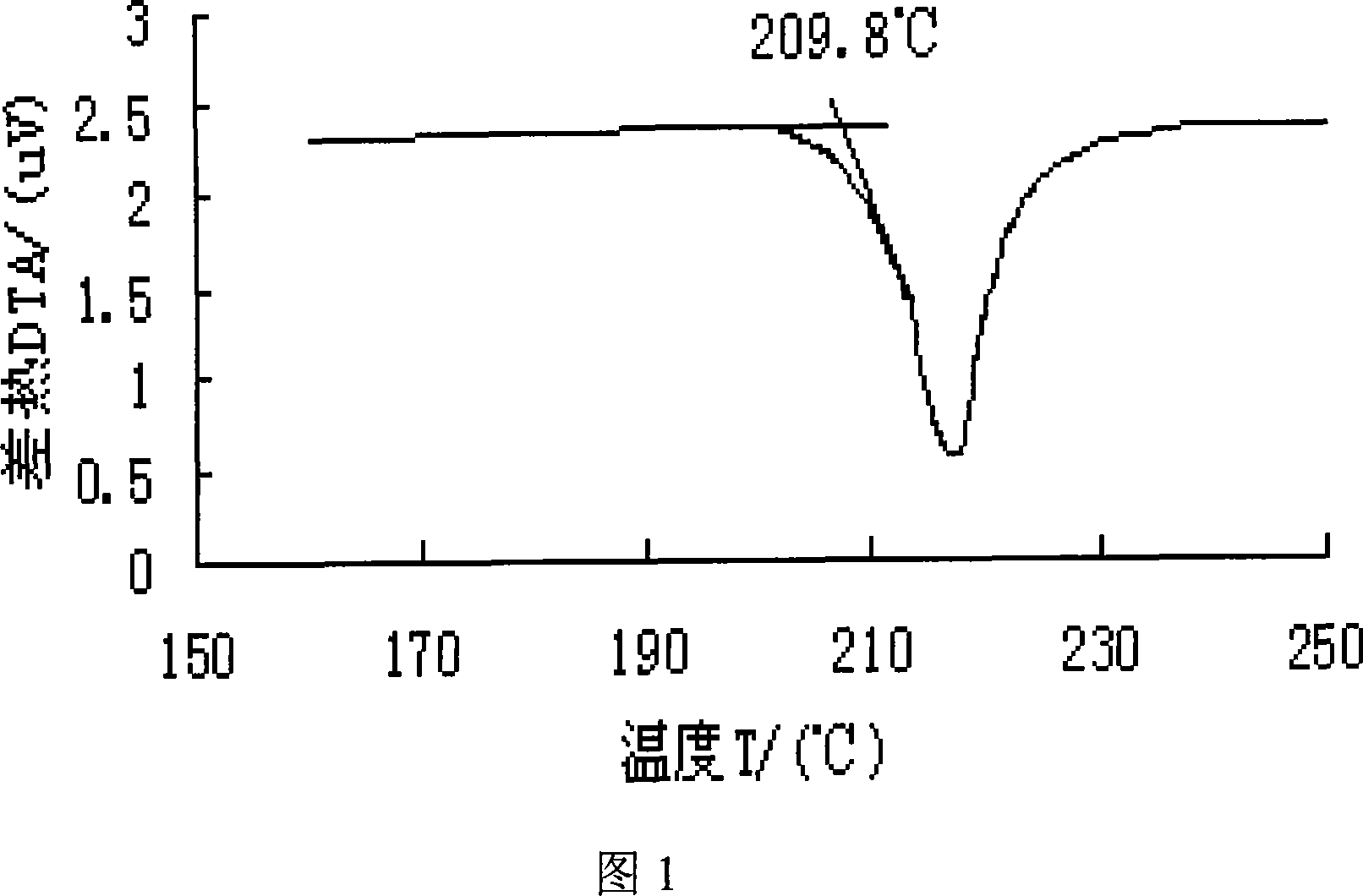

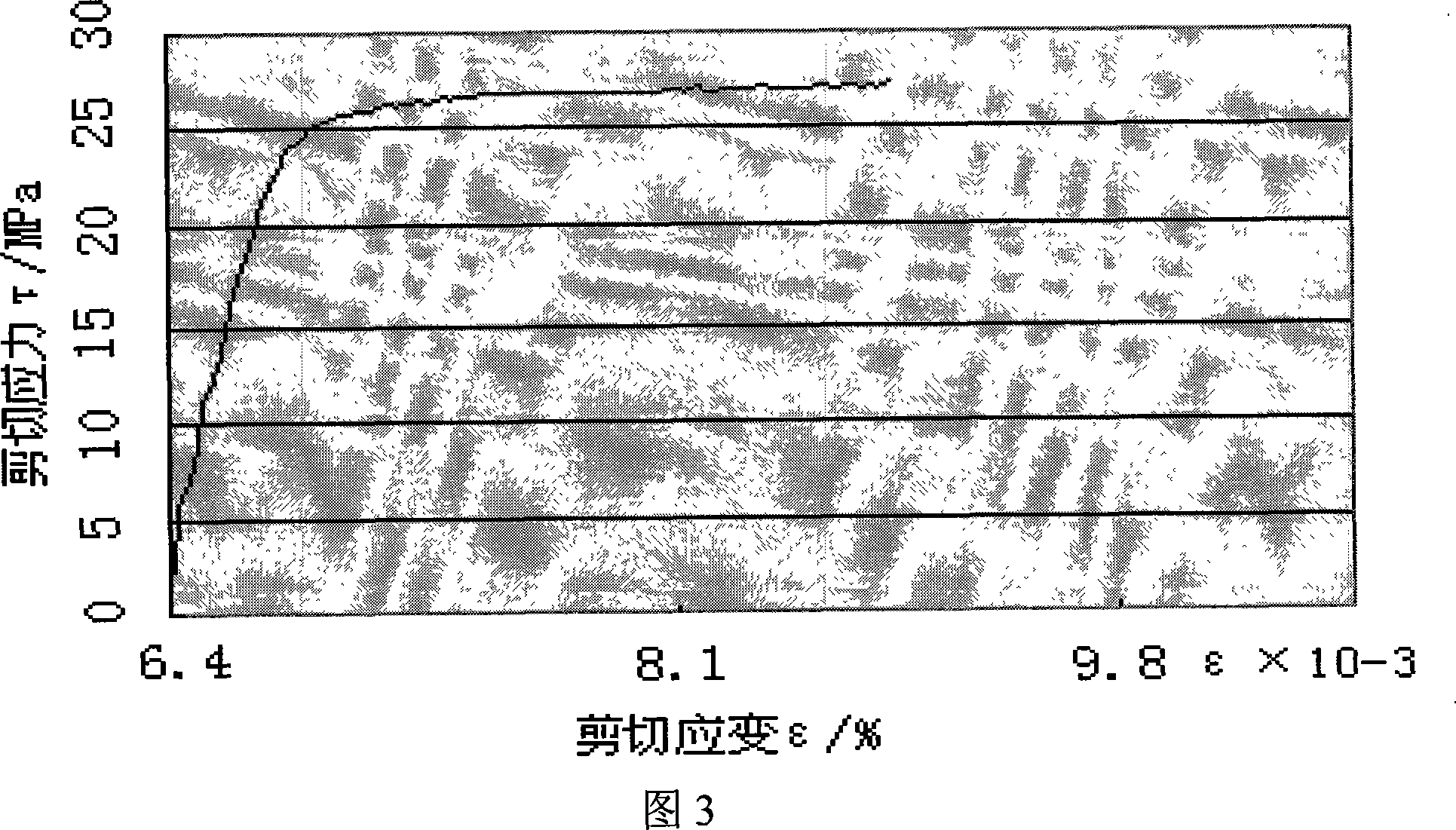

[0034] The cast ingot is prepared as a sample, and all aspects of its performance are tested. The allo...

Embodiment 2

[0040] 1. Take LiCl and KCl respectively at a mass ratio of 1.2:1 according to the LiCl:KCl component, which is 10 g in total, and mix them uniformly to prepare a protected molten salt;

[0041] 2. Take by weight respectively, Zn is 8.8g (8.8%), Cu is 1g (1.2%), mixed rare earth RE is 0.1g (0.1), and the rest is Sn, the total weight is 100%, and the quality is 100g in total. And put them all into a graphite crucible and stir them into a uniform mixture, cover the mixture in the crucible with the prepared protective molten salt, put the crucible in a well-type vacuum furnace for melting, vacuumize and fill it with high Pure nitrogen, when the furnace temperature reaches 650°C, keep it warm for 60 minutes, after melting, take out the crucible, pre-cool and cast the alloy;

[0042] 3. Remelt the casted alloy above at 420°C, keep it warm for 40 minutes, stir, and finally cast it into an ingot.

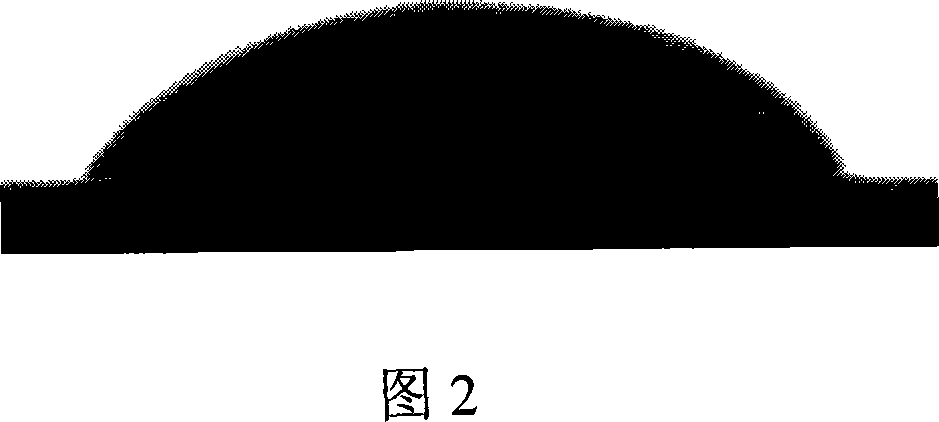

[0043] Wetting angle

Embodiment 3

[0045] 1. LiCl and KCl were taken in a mass ratio of 0.8:1.0 according to the LiCl:KCl component, which was 10 g in total, and mixed uniformly to prepare a protected molten salt;

[0046]2. Weigh respectively according to the mass ratio, Zn is 9.0g (9%), Cu is 3g (3%), mixed rare earth RE is 0.025g (0.025%), and the rest is Sn, the total weight is 100%, and the total mass is 100g , and put them all into a graphite crucible and stir into a uniform mixture, cover the mixture in the crucible with the prepared protective molten salt, place the crucible in a well-type vacuum furnace for melting, vacuumize and fill it with High-purity nitrogen, when the furnace temperature reaches 550°C, keep it warm for 90 minutes. After melting, take out the crucible, pre-cool and cast the alloy;

[0047] 3. Remelt the casted alloy above at 350°C, keep it warm for 60 minutes, stir, and finally cast it into an ingot to obtain the product.

[0048] The cast ingot is prepared as a sample, and all as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com