Elevator and elevator sheave

A technology for elevators, sheaves, ropes or cables for elevators, transmission elements or pulleys used in buildings, textile cables, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

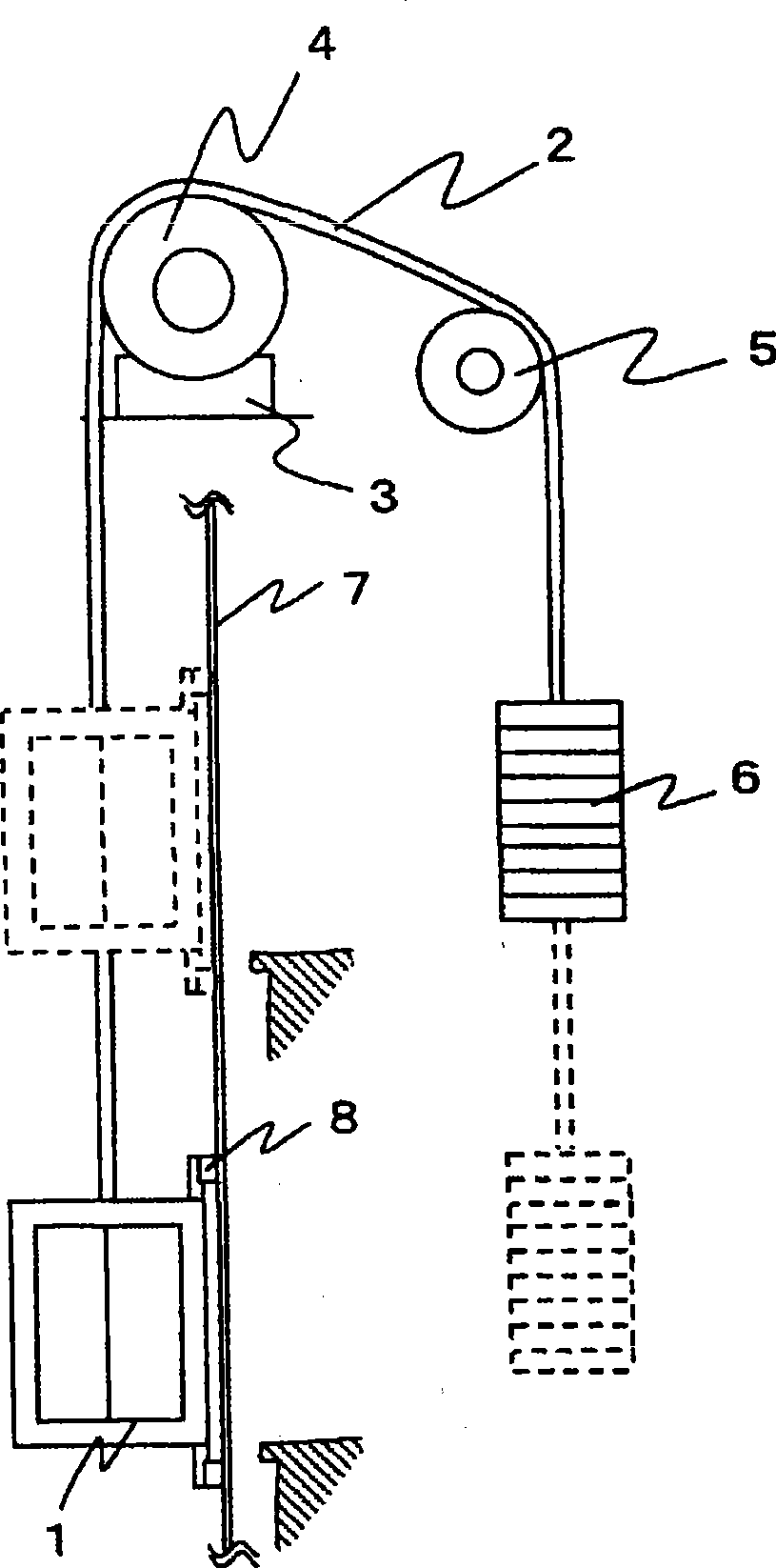

[0044] figure 1 It is a schematic diagram which shows the elevator which is one Example. exist figure 1 Among them, 1 represents the elevator car used to carry passengers, the elevator car 1 is connected with the sling 2, and the sling 2 is wound on the sheave 4 installed on the winch 3 . Furthermore, the sling 2 is connected to a counterweight 6 via a diverting pulley 5 . Guide rails 7 are arranged in the hoistway, and guide shoes 8 installed on the elevator car 1 clamp the guide rails 7 therebetween.

[0045] When the sheave 4 rotates under the drive of the winch 3, relying on the friction between the sling 2 and the sheave 4, the rotational force of the sheave 4 is transmitted to the sling 2 to move the sling 2, so that the elevator car The cabin 1 moves up and down in the hoistway along the guide rail 7 . figure 1 The dotted line part of represents the position of the elevator car and the counterweight when the elevator car 1 ascends a floor.

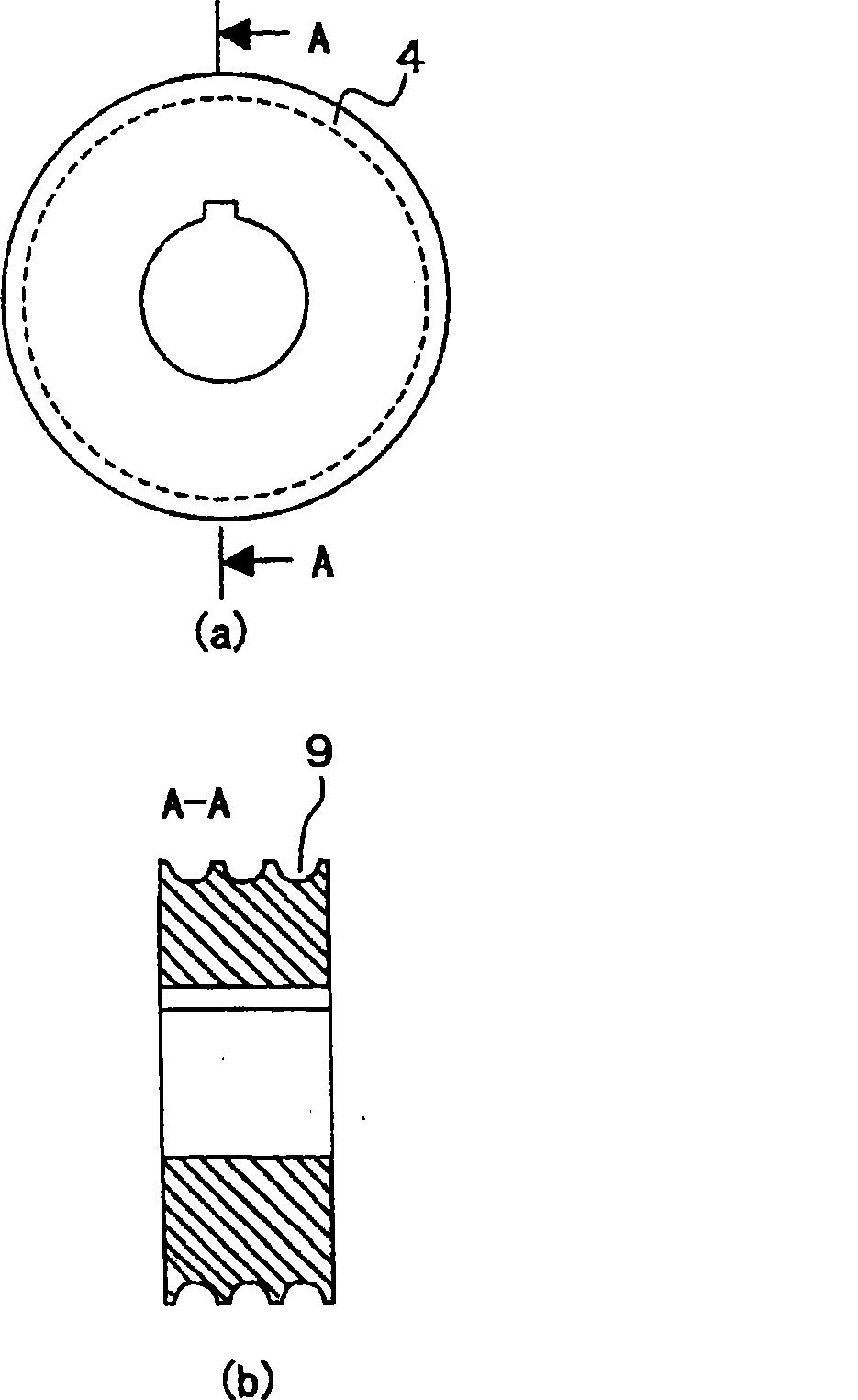

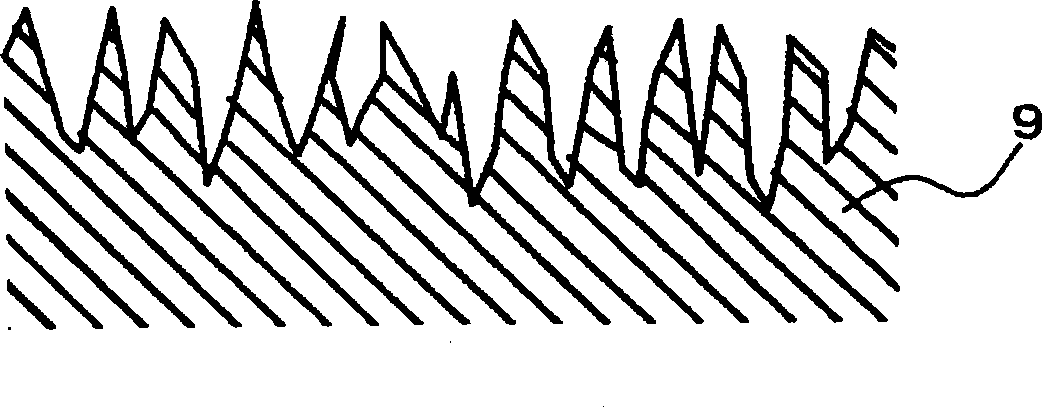

[0046] figure 2 (a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com