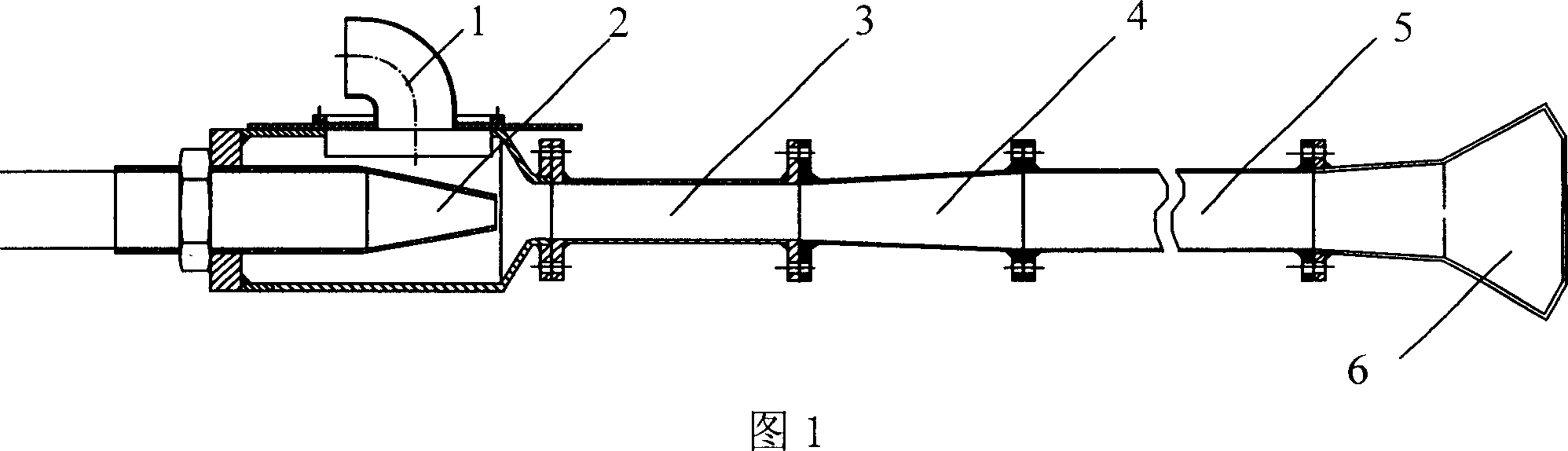

Detachable jet aerator and using method thereof

A jet aeration and split-type technology, applied in the field of water treatment, can solve problems such as not attracting enough attention, reducing air intake, increasing flow resistance, etc., to achieve rational use of input energy, improve oxygen utilization, and increase air bubbles quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

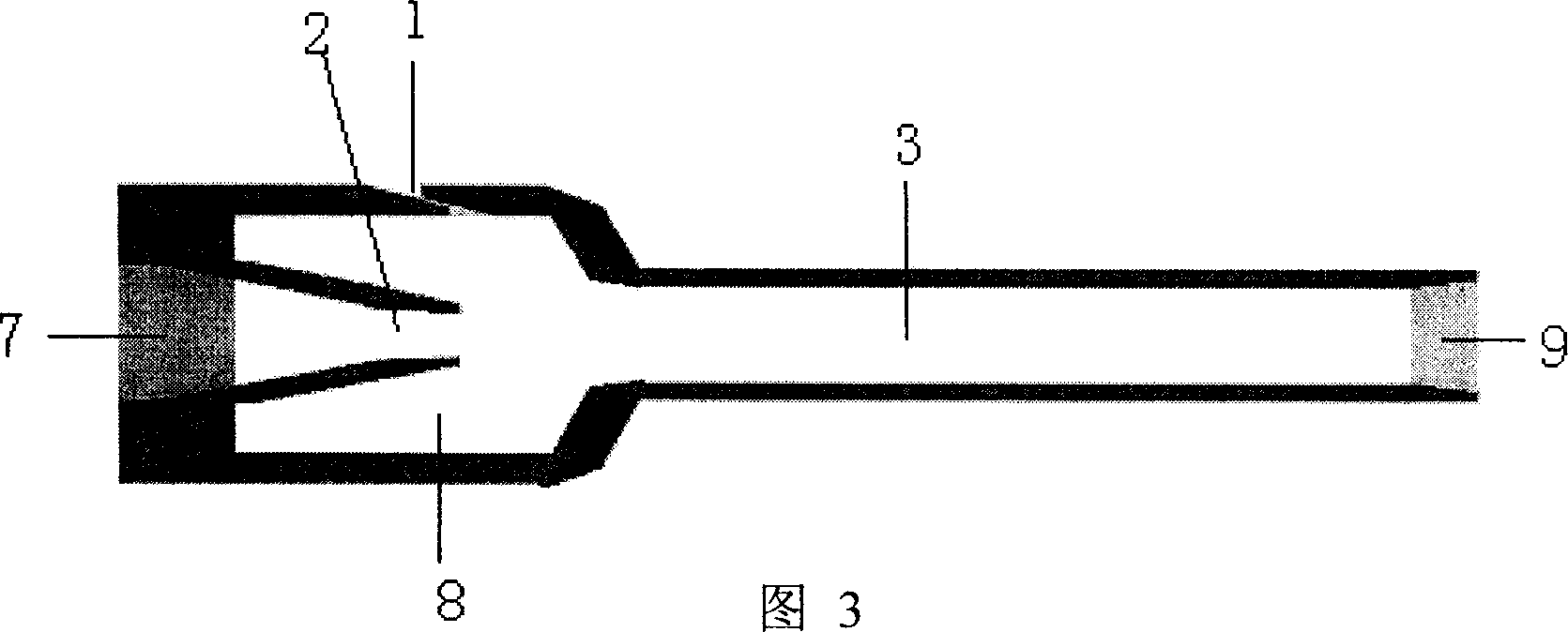

[0025] The research on the water distributor is an innovative point, and the name of the water distributor is generally called by the researchers according to its function. Its main function is to balance the contradiction between suction performance and agitation performance, promote the oblique and uniform flow of the three-phase mixed liquid, increase the agitation range of the jet aerator, and transfer the input energy to a wider water body, so as to achieve The purpose of rational utilization of input energy and energy saving.

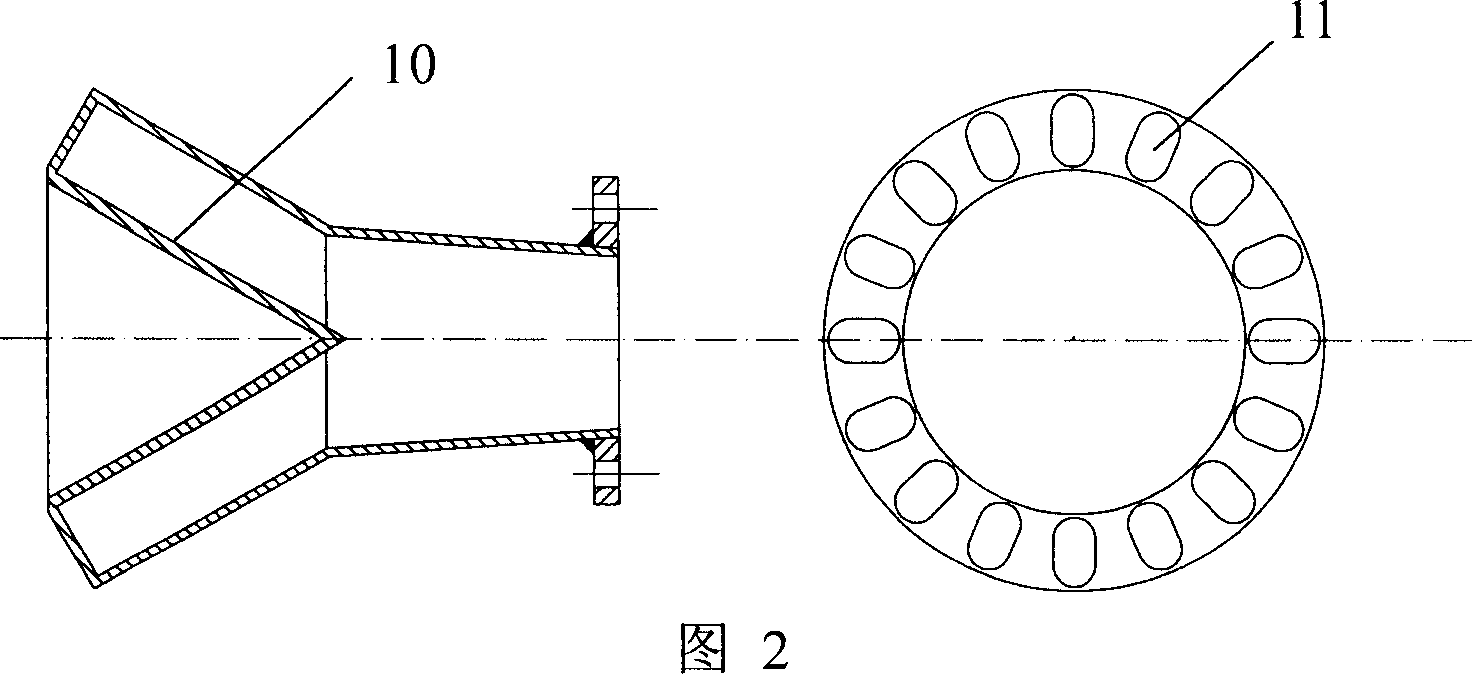

[0026] Specific working conditions: the water distributor 6 is installed at the rear of the tailpipe 5 and is connected by a flange, which is convenient for disassembly and maintenance. When working, when the gas-liquid foam flow enters the water distributor 6 through the tail pipe 5, because the internal design is equipped with a cone 10 with a certain angle, the flow of the mixed liquid will be deflected and flow from the water distributor at a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com