LED vapor film pattern forming method and device

A light-emitting diode and evaporation technology, which is applied in the field of light-emitting diode evaporation film pattern formation, can solve the problems of cumbersome, complicated, and difficult to manufacture lithography etching process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Please refer to Fig. 1, the method of the present invention comprises the following steps:

[0025] Step a: placing the carrier above the magnetic adsorption element;

[0026] Step b: placing the chip on the carrier; and

[0027] Step c: placing a non-magnetic metal mask on the surface of the chip, and using a magnetic adsorption element to absorb the non-magnetic metal mask to clamp and fix the chip to facilitate evaporation.

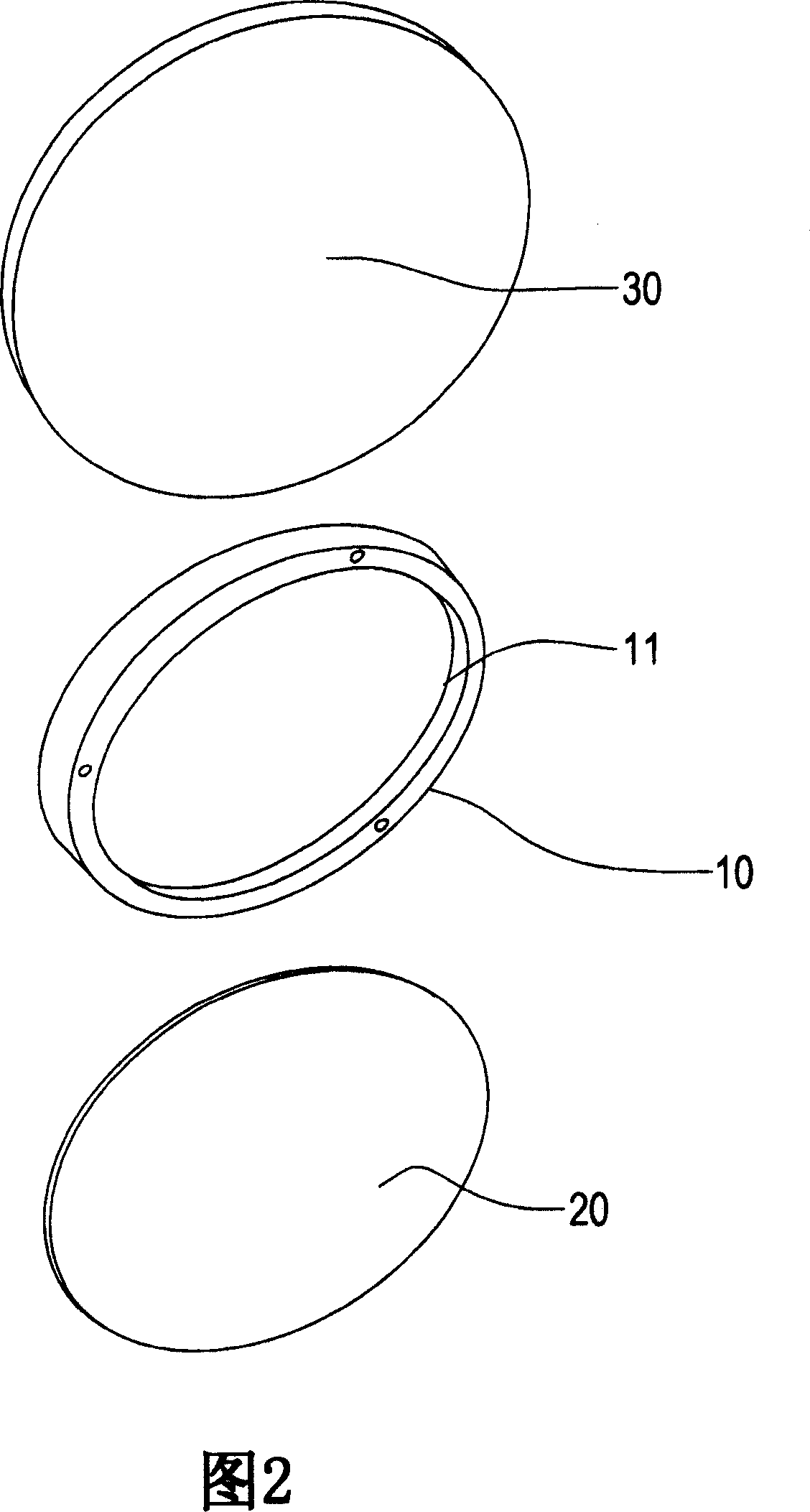

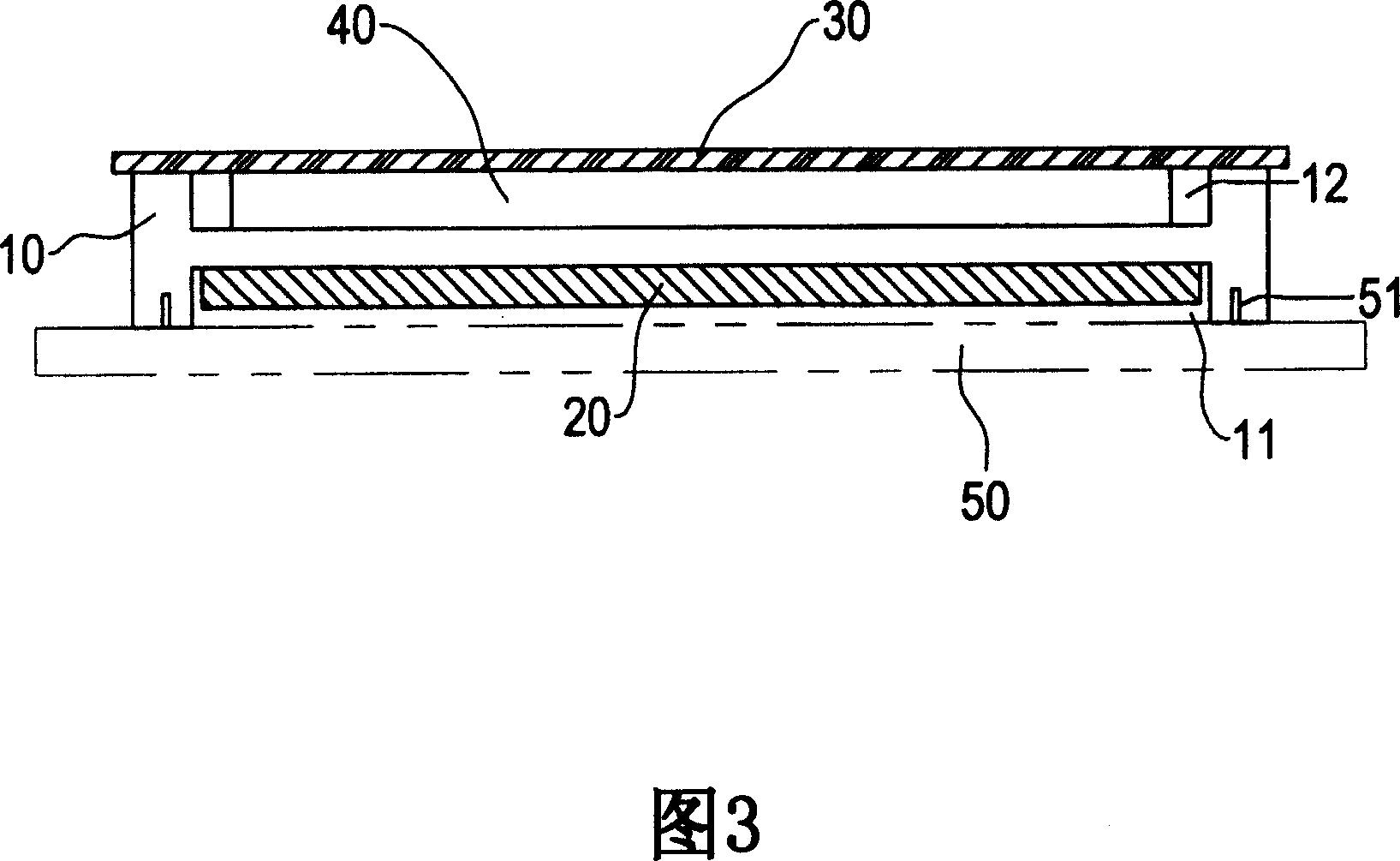

[0028] The device of the present invention comprises a carrier 10, a magnetic adsorption element 20 and a non-magnetic metal cover 30, as shown in FIG. A frame of appropriate length is extended above and below the peripheral edge of the carrier 10 so that accommodating spaces 11 and 12 are respectively formed above and below the carrier 10, and several positioning holes are provided on one side frame of the carrier 10.

[0029] The magnetic adsorption element 20 is provided in accordance with the shape of the carrier 10 and provided in the acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com