Extensible mirror body with shape memory material lining substrate

A technology of memory materials and mirrors, applied in the directions of mirrors, antennas, electrical components, etc., can solve the problems that aerospace mirrors cannot achieve a large expansion volume to shrinkage volume ratio, low precision, and small diameter, and shorten the production cycle. The effect of less system structure and control links and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

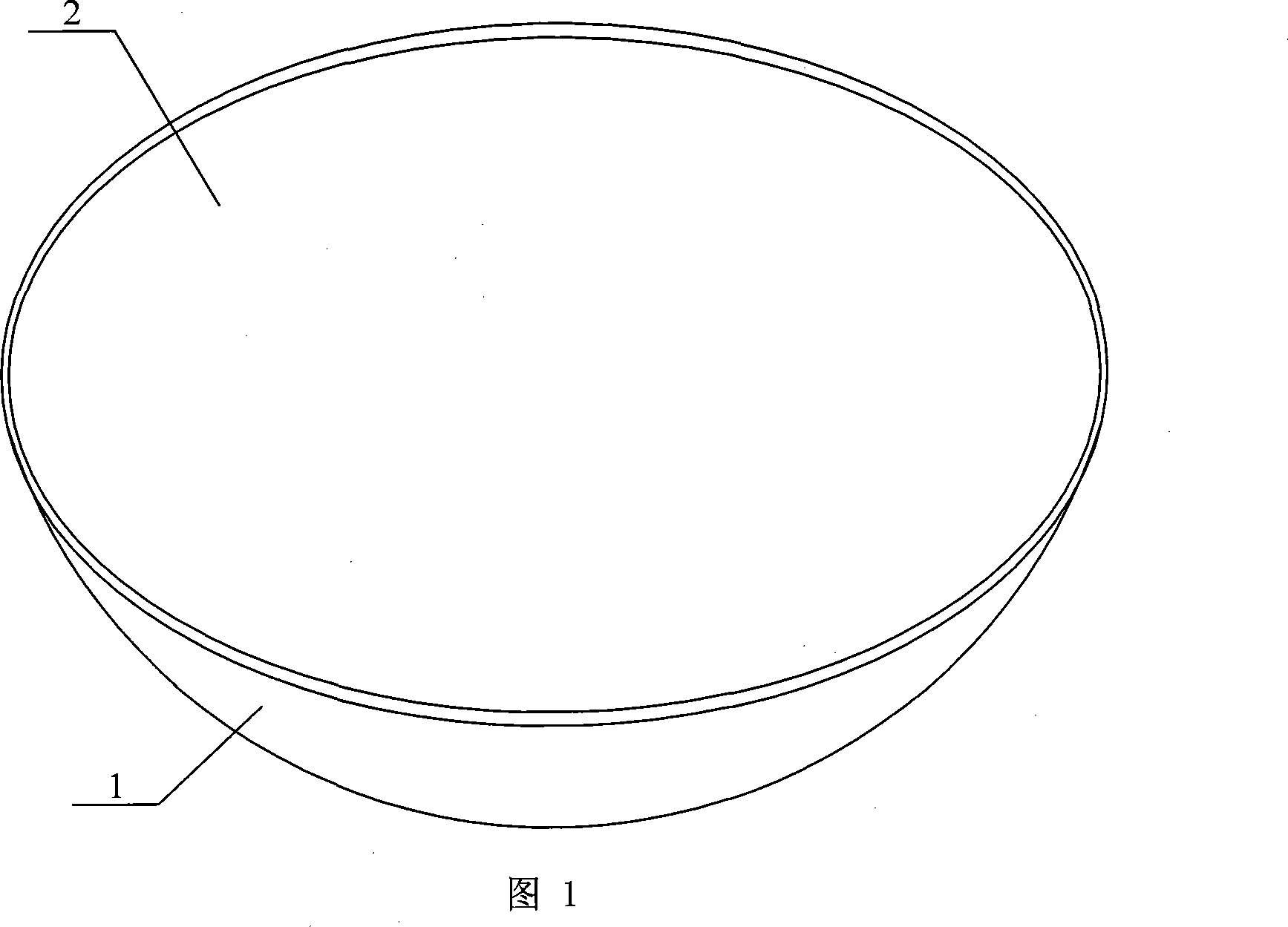

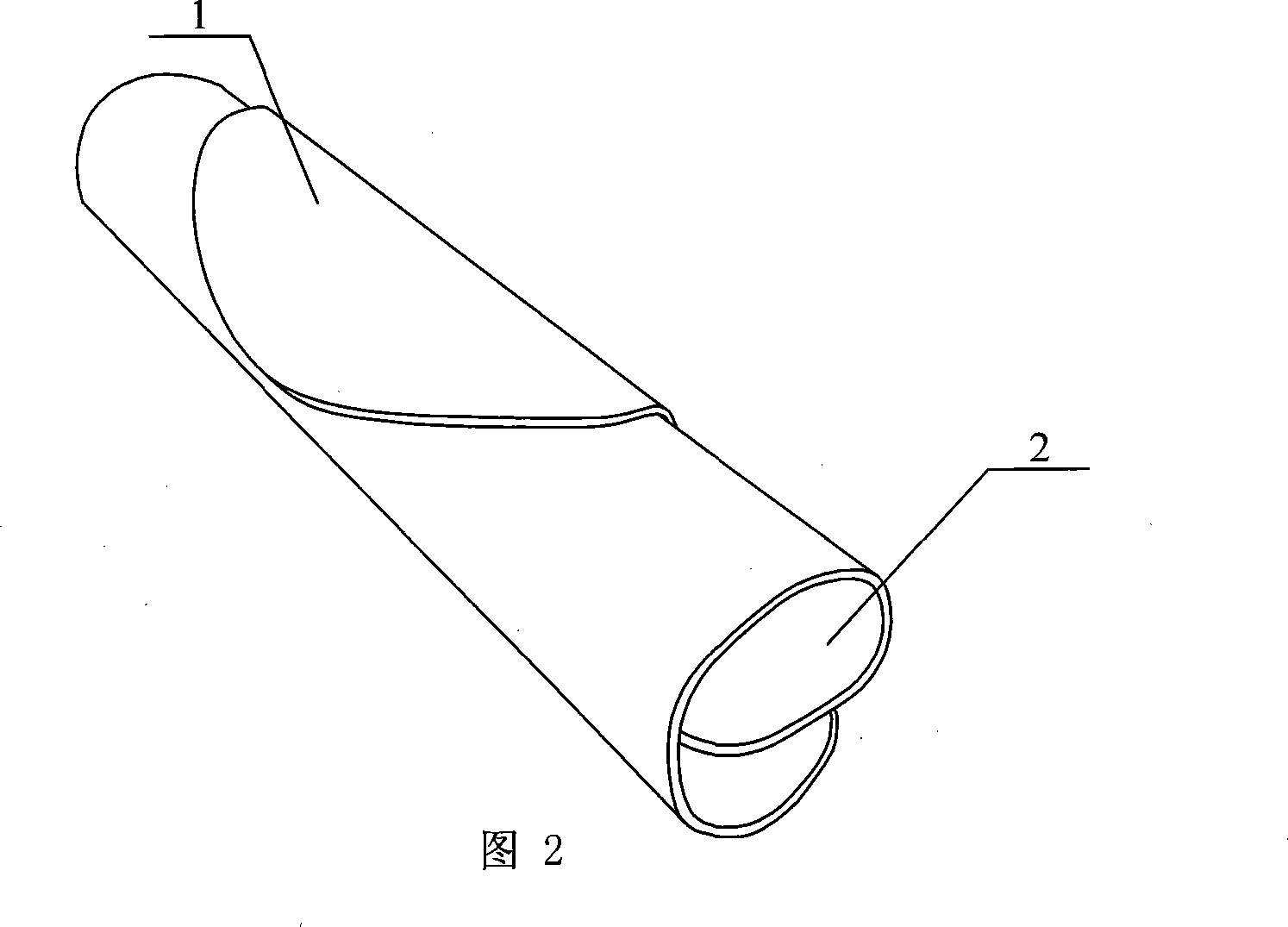

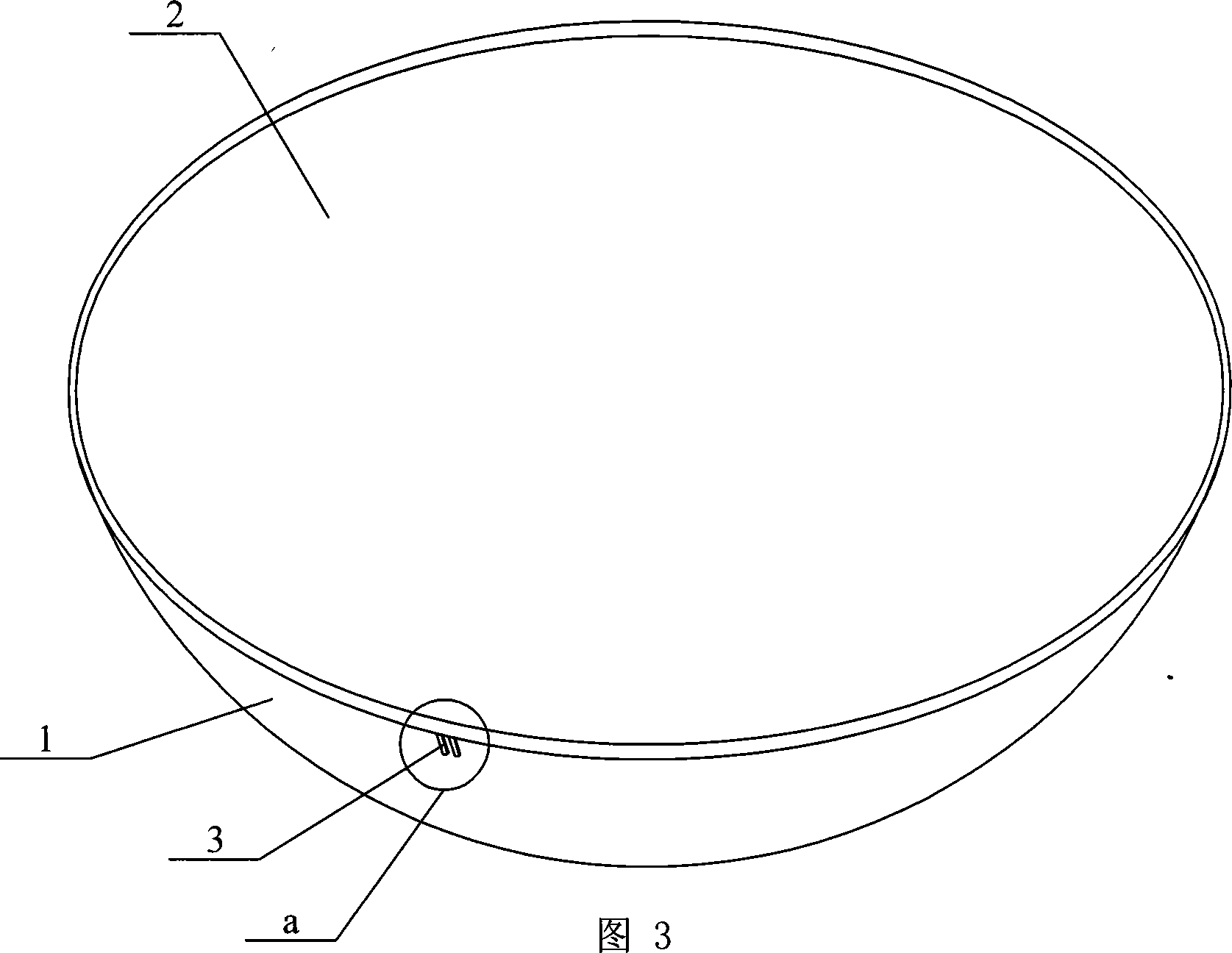

[0013] Embodiment 1: This embodiment is described in conjunction with Fig. 1 and Fig. 2. This embodiment is composed of a shape memory composite material base substrate 1 and a metal layer 2; the shape of the shape memory composite material base substrate 1 is a paraboloid, The inner surface of the base substrate 1 of shape memory composite material is electroplated with a metal layer 2 . The metal layer 2 provides a high-precision reflective surface, improves the surface smoothness of the expandable mirror body, and reduces its surface scattering rate. The shape-memory composite material underlay substrate 1 plays a dual role of carrying the structure and driving the structure to unfold.

specific Embodiment approach 2

[0014] Embodiment 2: This embodiment is described with reference to FIG. 1 and FIG. 2 . The difference between this embodiment and Embodiment 1 is that the thickness of the metal layer 2 is 0.001 mm to 1 mm, and the material of the metal layer is nickel metal. Other compositions and connection methods are the same as those in Embodiment 1.

specific Embodiment approach 3

[0015] Specific Embodiment 3: This embodiment will be described with reference to FIG. 1 and FIG. 2. The difference between this embodiment and Embodiment 1 is that the thickness of the shape memory composite substrate 1 is 0.1 mm to 80 mm. The focal length of the paraboloid of the backing substrate 1 and the aperture ratio of the paraboloid of the shape memory composite backing substrate 1 are 0.025-2.5; other components and connection methods are the same as those in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com