Method for manufacturing commutating support plate shaped shell of accurate casting heavy type combustion turbine

A technology of gas turbines and rectifying struts, which is applied to casting molding equipment, casting molds, and casting mold components. It can solve the problems of large size, many casting hot spots, and economic losses, and achieve high yield, reasonable strength, and good yield. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

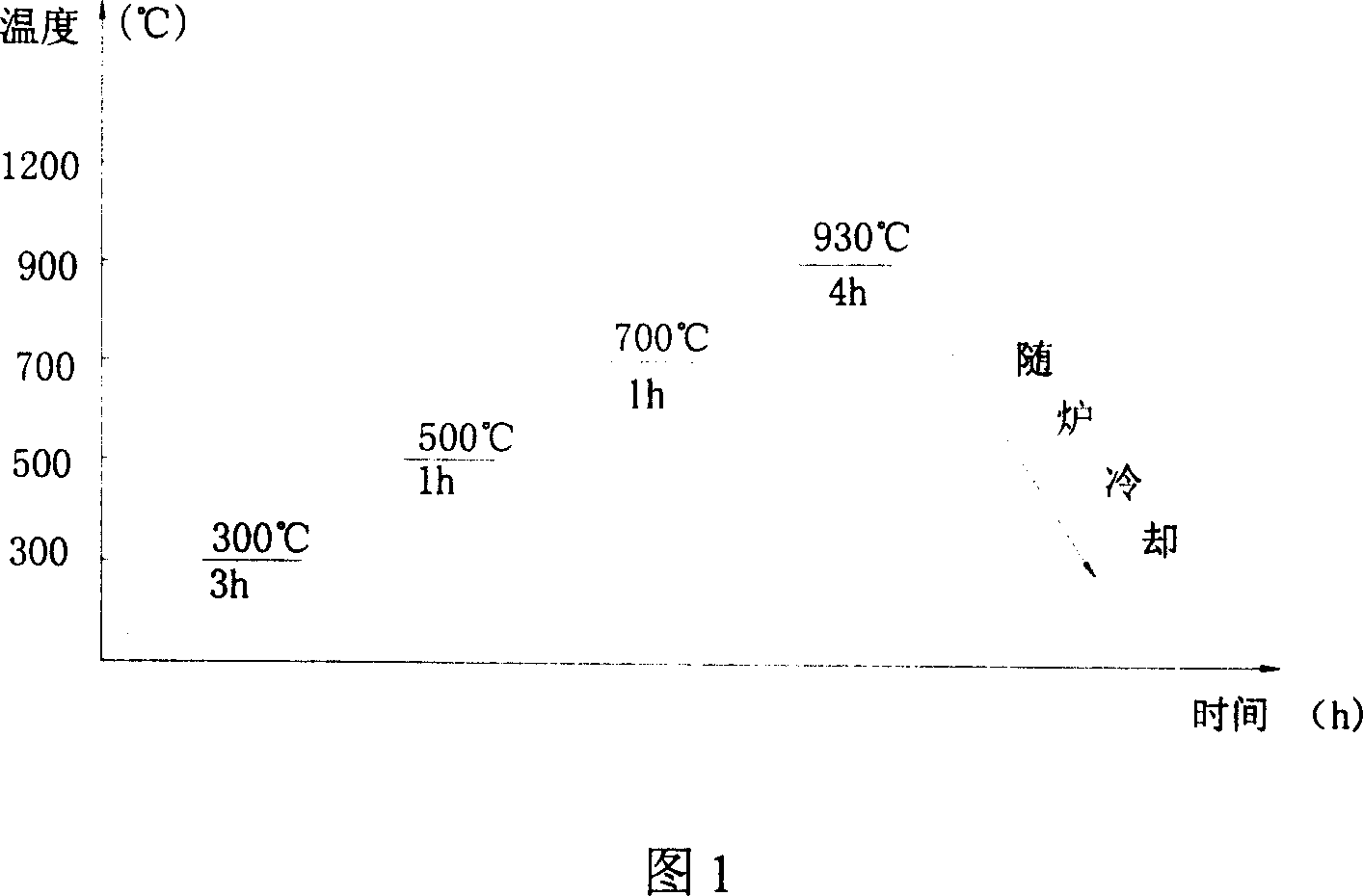

[0022] First, computer Ug modeling is carried out according to the technical requirements of the drawings (see Figure 1), and then the software design of the wax pattern combination and the location of the pouring system is carried out. Then, use computer simulation to verify whether the software design is reasonable, after simulation, repeated adjustments to determine the best process parameters. Finally, determine the combination scheme of the wax model and the pouring system (see Figure 2). Formwork manufacture is carried out from this combined solution.

[0023] A shell process:

[0024] Coating process flow: see Table 1

[0025] level

(second)

dry time

(Hour)

drying time

(Hour)

Material

level one

30

12

-

Corundum sand

80 mesh

Second floor

11

6

-

Corundum sand

the third floor

10

-

6

Corundum ...

Embodiment 2

[0033] The difference from Example 1 is that the coating process is shown in Table 3, the firing process is 300-500°C for 5 hours, and 930±10°C for 2 hours.

[0034] level

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com