Prepn process of germanium dioxide powder

A germanium dioxide and powder technology is applied in the field of preparation of inorganic catalysts, which can solve problems such as agglomeration, difficult hydrolysis process, bonding growth, etc., and achieve the effects of reducing content, avoiding agglomeration, and promoting rapid progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

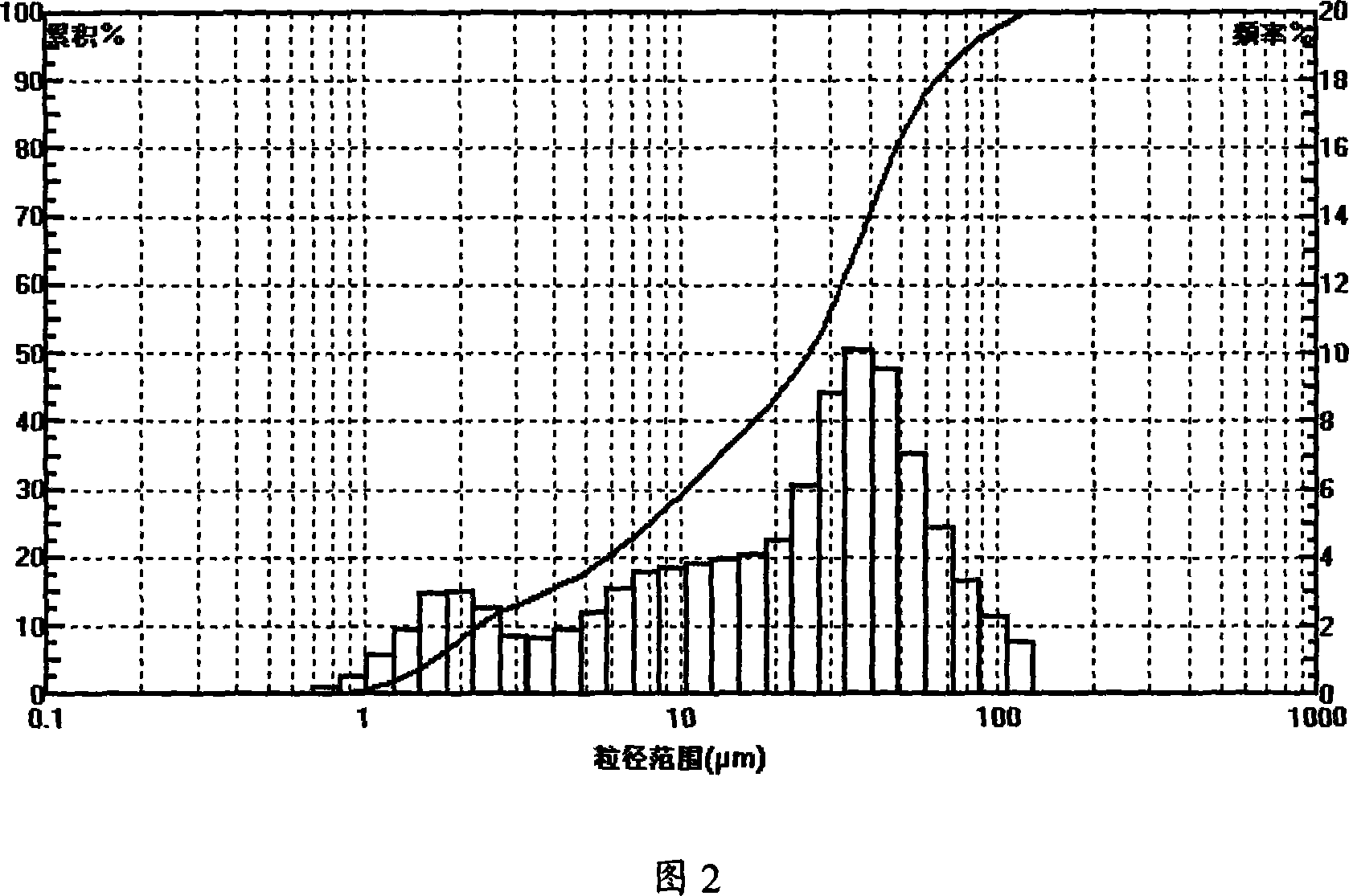

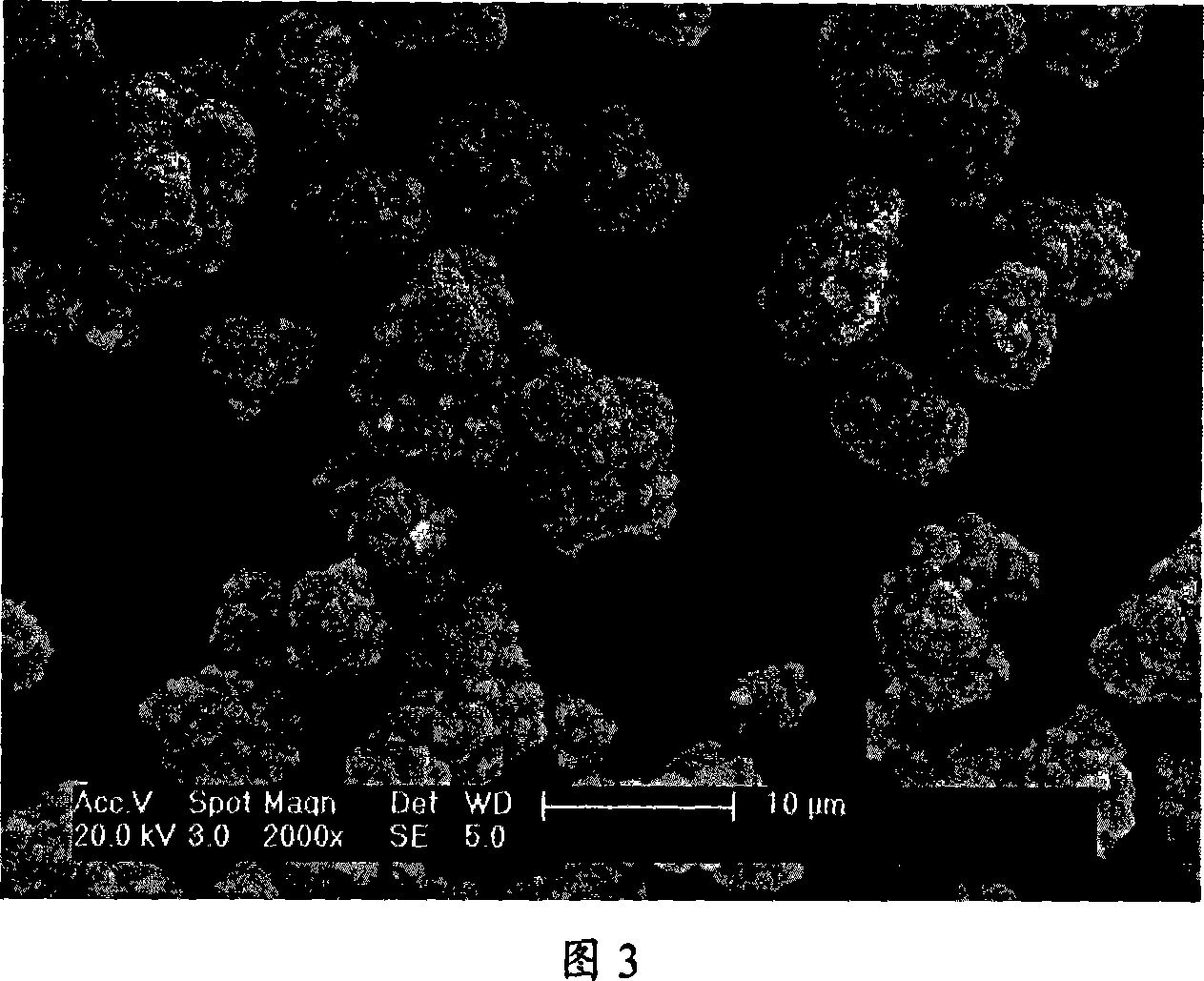

[0016] high purity GeCl 4 solution, GeCl by volume 4 :H 2 Slowly add O=1:9 ratio to electronic grade deionized water for hydrolysis, and feed while stirring. The feeding speed is 30ml / min; the stirring speed is 1000 rpm; the hydrolysis process temperature is controlled at 10°C; after the feeding is completed, the stirring paddle continues to stir, the stirring speed is 800 rpm, the ultrasonic oscillation frequency is 40KHz, the oscillation power is 100W, and the time is 20min; 2 The particles were washed with water and dried at 180°C for 8 hours to obtain GeO with a central particle size of 5 μm. 2 powder.

Embodiment 2

[0018] high purity GeCl 4 solution, GeCl by volume 4 :H 2 Slowly add O=1:7 ratio to electronic grade deionized water for hydrolysis, and feed while stirring. The feeding speed is 30ml / min; 10°C; after the feeding is completed, the stirring paddle continues to stir, the stirring speed is 800 rpm, the ultrasonic oscillation frequency is 40KHz, the oscillation power is 50W, and the time is 30min; 2 The particles were washed with water and dried at 180°C for 8 hours to obtain GeO with a central particle size of 6 μm. 2 powder.

Embodiment 3

[0020] high purity GeCl 4 solution, GeCl by volume 4 :H 2 The ratio of O=1:7.5 is slowly added to electronic grade deionized water for hydrolysis, while stirring, the feeding speed is 50ml / min; the stirring speed is 1000 rpm; the temperature of the hydrolysis process is controlled at 5°C; after feeding, the stirring paddle continued to stir, the stirring speed was 700 rpm, the ultrasonic oscillation frequency was 40KHz, the oscillation power was 80W, and the time was 20min; 2 The particles were washed with water and dried at 180°C for 8 hours to obtain GeO with a central particle size of 6 μm. 2 powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com