Control device for fully-automatic constant-flow super-filtering water treatment

A control device and constant flow technology, which is applied in the field of membrane separation technology and water treatment, can solve the problems of difficult to meet the application of membrane treatment, complex operation of the control process, low degree of automation, etc., to achieve real-time observation, advanced technology, and filtration accuracy high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

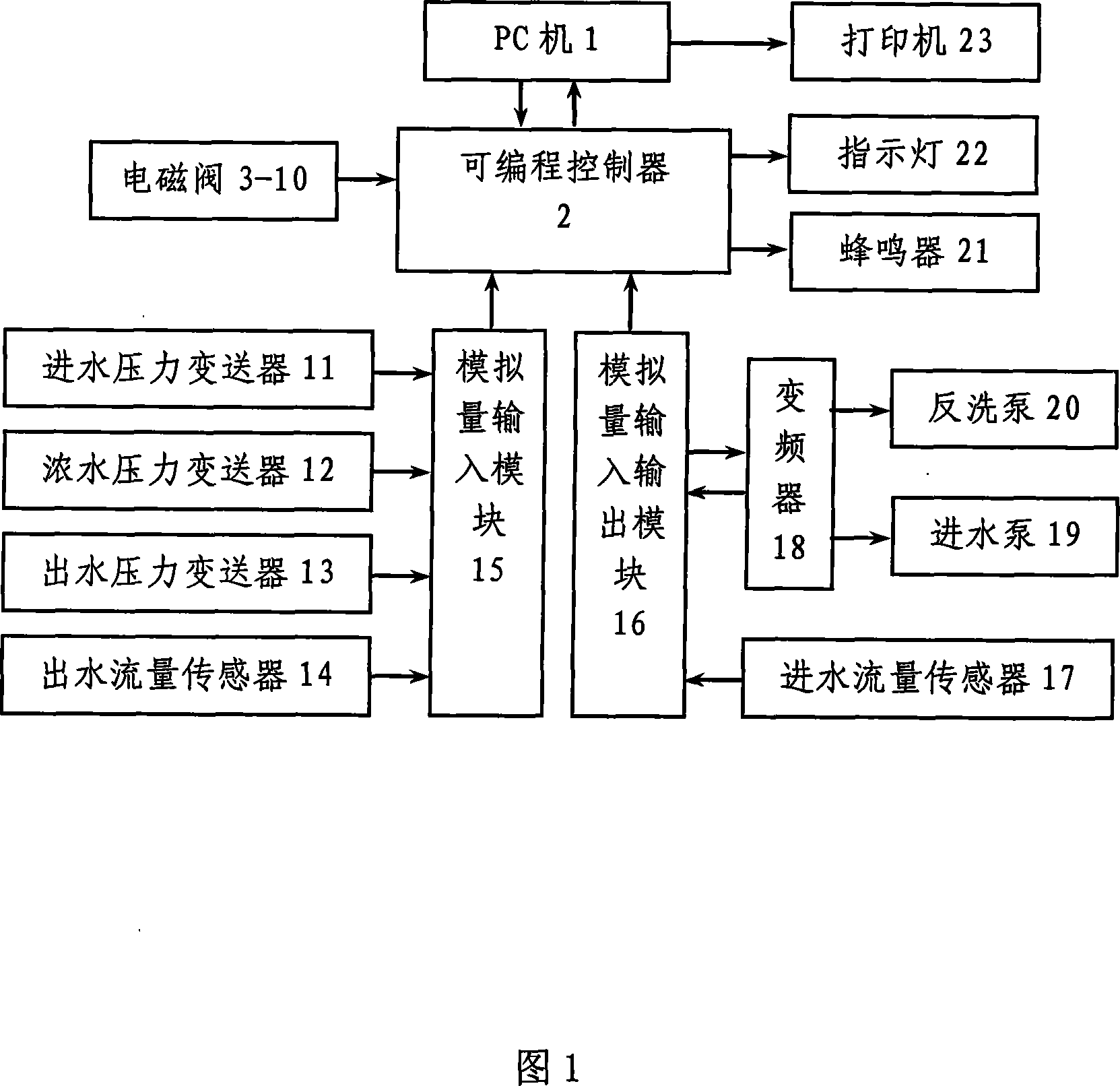

[0026] The programmable controller used among the present invention is SIMATIC S7-200, and its CPU unit is CPU226, itself has 24 digital quantity input and 16 digital output ports. The analog quantity input module adopts EM231 and has 4 analog quantity input ports. The analog input and output module adopts EM235, which has 4 analog input ports and 1 analog output port. The inverter adopts Siemens MMV420 inverter.

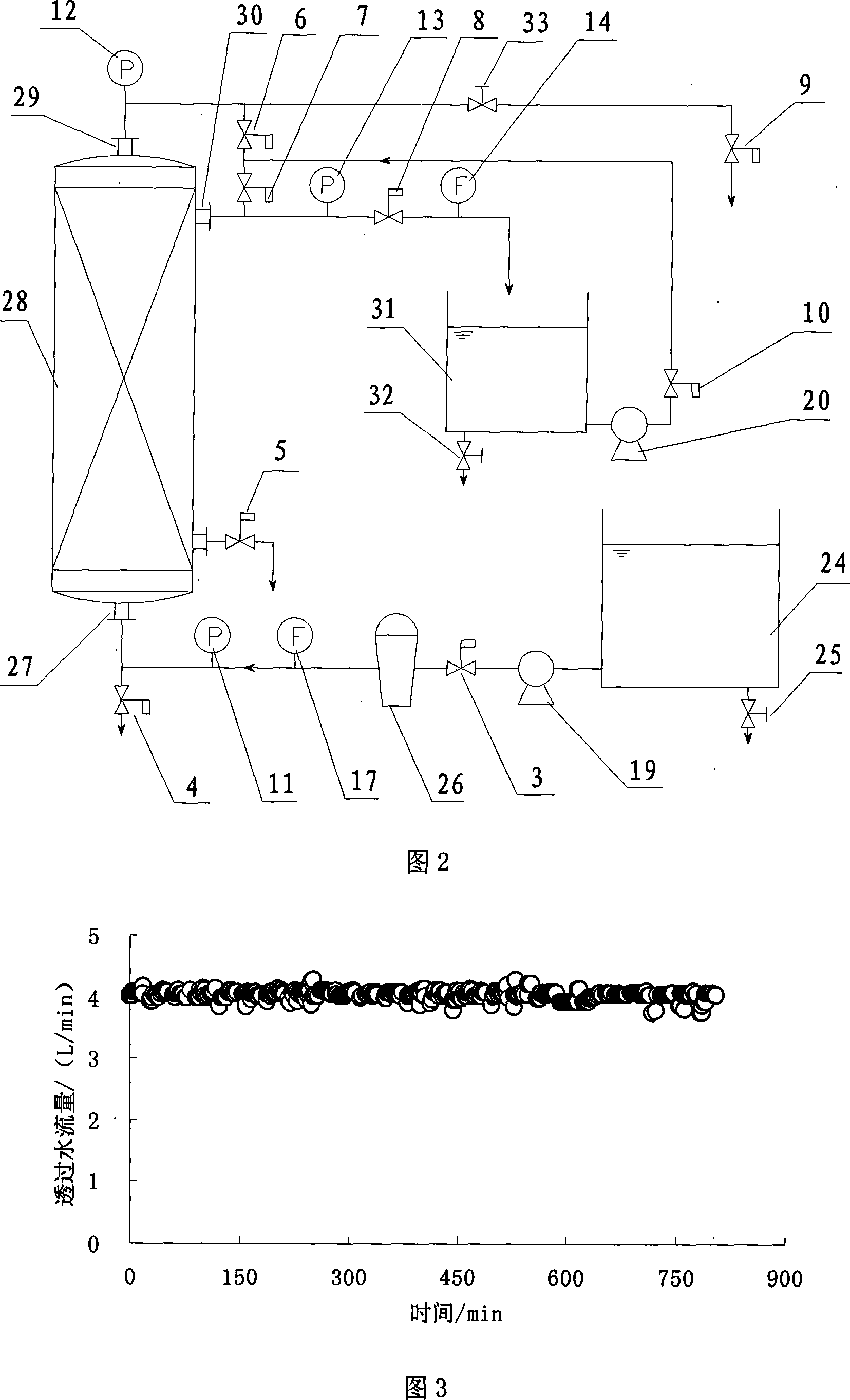

[0027] Fig. 2 is the implementation structure diagram of the present invention, the raw water to be treated is pressurized by the raw water tank 24 through the water inlet pressure pump 19, enters the security filter 26 through the electromagnetic valve 3, and then flows through the water inlet flow sensor 17 and the water inlet The pressure transmitter 11 enters the ultrafiltration membrane from the water inlet 27 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com