Method for preparing aluminium alloy composite material for brazing type heat transmission

A composite material and manufacturing method technology, applied in metal rolling, manufacturing tools, metal rolling, etc., can solve the problems of environmental pollution, energy consumption, etc., and achieve the effect of preventing oxidation and reflecting good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

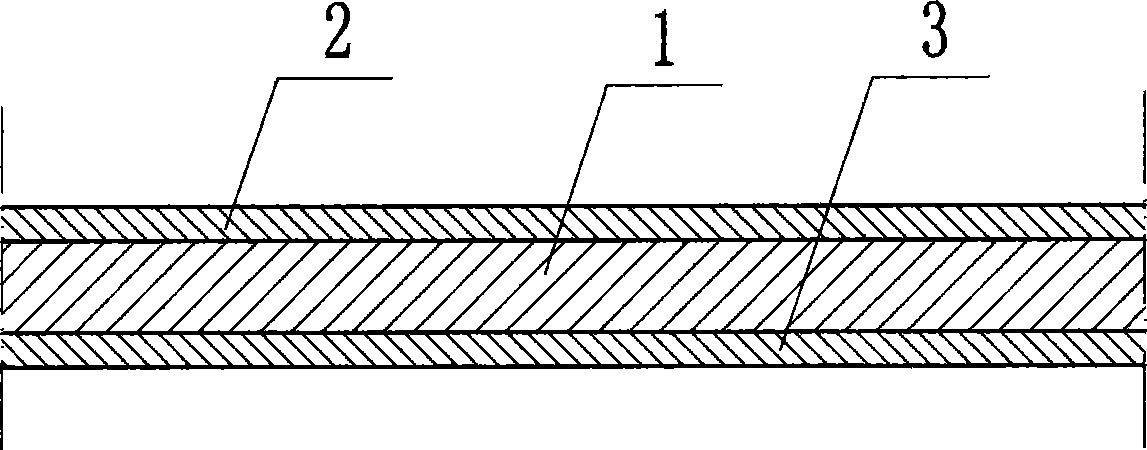

[0019] Aluminum alloy composite materials for heat transmission are welded aluminum alloy strips of different materials, rolled together at high temperature and high pressure on a hot rolling mill, and then cold rolled to finished products. According to different performances, each layer has the function of each layer. The composite material consists of two to three layers: ① its first layer is used for brazing, the second layer is the substrate, and the third layer is the waterproof layer; ② both sides of the substrate are composite brazing layers; ③ one side of the substrate is composite brazing layer.

[0020] Composite material matrix adopts AA3003, brazing layer adopts AA4343 or AA4045, and waterproof layer adopts AA7072. The selection of materials combines the advantages of core material and cladding layer material.

[0021] This embodiment describes the present invention in detail with a three-layer composite material.

[0022] The first step: according to the performa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com